- Home

- Blog

- Top-rated Electric Car Polisher Pads: Enhance Your Vehicle's Shine with High-quality Polishing Pads

Top-rated Electric Car Polisher Pads: Enhance Your Vehicle's Shine with High-quality Polishing Pads

By:Admin

Introduction:

In the era of environmentally conscious initiatives and increasing popularity of electric vehicles, the automotive industry is experiencing a significant shift towards sustainable and efficient solutions. In line with this trend, a renowned manufacturer in the car care industry has developed an innovative line of Electric Car Polisher Pads that revolutionizes the polishing process for electric vehicles.

Company Introduction: (Brand name removed for compliance with user request)

With over two decades of experience in the car care industry, the company has established itself as a trusted provider of high-quality car care products. They are known for their commitment to innovation, environmental responsibility, and customer satisfaction. Building upon their expertise, they have created an exceptional range of Electric Car Polisher Pads specifically designed to cater to the unique needs of electric vehicle owners.

Article:

The unveiling of Electric Car Polisher Pads marks a significant advancement in car polishing technology. These pads not only ensure optimal results in terms of shine and polish but also contribute to the overall sustainability of the automotive industry. Let's delve deeper into the features and benefits of this ground-breaking product.

1. Superior Polishing Performance and Efficiency:

The Electric Car Polisher Pads have been engineered with advanced technology to deliver exceptional polishing performance. Their specially formulated materials prevent scratches, swirl marks, and holograms, leaving electric vehicle surfaces flawlessly clean and shiny. The velcro backing ensures quick and easy pad changes, reducing downtime during the polishing process and allowing users to complete the task efficiently.

2. Environmentally Friendly Materials:

The company has prioritized environmental responsibility while manufacturing these pads. They are proud to claim that all materials used in their Electric Car Polisher Pads are eco-friendly, with no harmful chemicals or toxins. This commitment to sustainability aligns perfectly with the eco-conscious electric vehicle owners who strive to minimize their carbon footprint.

3. Versatility and Compatibility:

Recognizing the diverse range of electric vehicles in the market, the Electric Car Polisher Pads come in various sizes and types. Whether it's a compact electric sedan or a large electric SUV, car owners can find the perfect pad size to suit their vehicle's unique requirements. Additionally, these pads are compatible with most electric car polishers available on the market, ensuring a smooth and hassle-free experience.

4. Longevity and Durability:

The company's meticulous attention to detail ensures that the Electric Car Polisher Pads are durable and long-lasting. With proper maintenance and care, these pads can be used for multiple polishing sessions, providing value for money to customers while reducing waste in the long run.

5. User-Friendly Design:

The Electric Car Polisher Pads have been designed with user convenience in mind. The ergonomically shaped pads provide a comfortable grip, reducing hand fatigue during polishing sessions. Furthermore, their efficient heat dissipation properties prevent overheating, enabling extended usage without compromising performance.

Conclusion:

The introduction of the Electric Car Polisher Pads represents a significant milestone in the car care industry, particularly for electric vehicle owners. By combining superior polishing performance, environmental responsibility, versatility, and user-friendly design, this product sets new standards in car polishing technology. With these pads, electric vehicle owners can maintain a showroom-quality shine while reducing their environmental impact. As the automotive industry continues to evolve, innovative products like Electric Car Polisher Pads play a crucial role in meeting the changing demands of environmentally conscious consumers.

Company News & Blog

Discover the Efficiency and Precision of 125mm Grinding Wheels for All Your Grinding Needs

Introducing the Next Generation Grinding Wheel: A 125mm Innovation for Enhanced PerformanceInnovation has always been a quintessential aspect of every industry, driving progress and redefining standards. The grinding wheel industry is no exception, constantly striving to achieve greater efficiency, precision, and durability in the pursuit of excellence. Embracing this spirit of innovation, {}, a renowned name in the field, proudly presents their latest breakthrough - the 125mm Grinding Wheel. By removing the brand name for the purpose of this article, we aim to highlight the compelling features and benefits that make this new product a game-changer.Designed to cater to the evolving needs of professionals in material processing, the 125mm Grinding Wheel is poised to revolutionize the grinding experience. Boasting improved performance and extended longevity, this innovative tool promises to take productivity to new heights. In conjunction with our company's philosophy of delivering cutting-edge solutions, the introduction of this state-of-the-art grinding wheel reaffirms our commitment to customer satisfaction.Now, let's dive deeper into the unique features that make the 125mm Grinding Wheel stand out from its counterparts. The first notable attribute is its superior abrasive grain composition, carefully selected to ensure optimal performance. This high-quality abrasive material guarantees exceptional cutting capabilities, facilitating smooth and efficient grinding operations. Coupled with a meticulously engineered bond system, the wheel exhibits outstanding strength and durability, ensuring a prolonged lifespan.Furthermore, the innovative design of the 125mm Grinding Wheel enables enhanced heat dissipation. This feature prevents overheating and subsequent thermal damage to the workpiece, a common concern during intense grinding processes. By reducing the risk of burns and stress-induced deformities, the wheel ensures greater precision, making it an ideal choice for tasks that demand utmost accuracy.Another significant advantage of the 125mm Grinding Wheel is its unmatched versatility. It excels in grinding various materials, including metals, ceramics, and stone, making it an indispensable tool across a wide range of applications. This adaptability not only enhances user convenience but also reduces the need for multiple grinding tools, simplifying operations and streamlining workflows.In addition to its exceptional functionality, the 125mm Grinding Wheel prioritizes user safety. By incorporating advanced features like reduced vibration and noise suppression, the wheel significantly minimizes operator discomfort and fatigue. This not only promotes a healthier working environment but also enhances overall productivity by allowing professionals to work for extended periods without unnecessary interruptions.One cannot overlook the environmental aspect of this new grinding wheel. As an environmentally conscious company, {} has ensured that the manufacturing process of the 125mm Grinding Wheel adheres to sustainability guidelines. By utilizing eco-friendly materials and employing energy-efficient production techniques, we aim to minimize our carbon footprint and contribute to a greener future.The launch of the 125mm Grinding Wheel signifies a turning point in the grinding wheel industry, offering professionals a dependable and efficient tool that surpasses expectations. At {}, we understand the diverse needs of our customers and constantly endeavor to develop cutting-edge solutions to meet them. This latest addition to our product line reaffirms our commitment to innovation, quality, and customer satisfaction.In conclusion, the 125mm Grinding Wheel, with its superior performance, extended longevity, versatility, enhanced safety features, and eco-friendly production, represents a breakthrough in the field of grinding tools. With its introduction to the market, professionals can expect unprecedented grinding efficiency, allowing them to accomplish tasks with utmost precision and ease. As pioneers in the industry, {} continues to lead the way, offering innovative tools that empower professionals to transform their visions into reality.

Efficient Polishing Tools Boosting Your SEO Performance for Optimal Results

article as below:Polishing Tools: A Step Ahead in Metalworking IndustryPolishing tools play a crucial role in the metalworking industry. They are used to remove any unwanted material from the surface of metalworkpieces to provide them with a smooth and shiny finish. Polishing tools are also used to improve the surface quality of metal workpieces, making them more durable and appealing. One company leading the way in the development of advanced polishing tools is based in the United States.This company (we will refer to it as the company throughout the article) was established with the objective of providing state-of-the-art polishing tools that are efficient, durable and easy to use. Since its inception, the company has remained true to its mission by consistently producing top-quality polishing tools used widely in the metalworking industry.The company's range of polishing tools includes grinding wheels, abrasive belts, and flap discs. These polishing tools are designed to meet the varying needs of different types of metal workpieces and different surface finishes. The tools are used in different parts of the process, including smoothing, grinding, polishing and finishing.One of the key features of the company's polishing tools is their durability. The tools are made from high-quality materials that are engineered to withstand heavy usage and provide long-lasting performance. This is a major advantage for metalworking companies that depend on the efficiency of their equipment to meet their production targets. The durability of the tools ensures minimal downtime, reduced maintenance cost, and maximum productivity.Another important aspect of the company's polishing tools is their ease of use. The tools are designed to be user-friendly, allowing workers to operate them efficiently without any difficulty. This is particularly important for metalworking companies that employ a large number of workers. With easy-to-use tools, companies can ensure that workers can produce the desired results with minimal supervision.The company has invested heavily in research and development to ensure that its polishing tools remain ahead of the competition. Through its state-of-the-art research facilities, the company has developed several innovative polishing tools that have further improved efficiency and productivity in the metalworking industry.One of the company's recent developments is a range of environmentally friendly polishing tools. The company recognizes the need for companies to prioritize environmental sustainability in their operations. Consequently, it has developed polishing tools that do not pose any harm to the environment. These tools are made from sustainable materials and are designed to reduce the need for excessive polishing, consequently reducing waste.The company also understands the importance of providing excellent customer service. It employs a team of experienced and knowledgeable professionals who are always ready to assist customers with any queries or issues they may encounter with the tools. This has earned the company a reputation for providing reliable and effective customer support.The company's commitment to excellence has also seen it forge partnerships with other industry players. These partnerships have enabled the company to gain access to cutting-edge production technology and industry expertise that have further enhanced the quality of its polishing tools.In conclusion, polishing tools are an essential element of the metalworking industry. They are used to provide metal workpieces with a smooth and shiny finish, which enhances their durability and appeal. The company is at the forefront of the development of top-quality polishing tools that are efficient, durable, and easy to use. With its commitment to research and development, excellent customer service, and partnerships, the company is poised to remain a leading player in the metalworking industry for years to come.

Best Concrete Polishing Blades: A Complete Guide

Title: Innovative Concrete Polishing Blades Revolutionize Construction IndustryIntroduction:[Company Name], a pioneering name in the construction industry, has recently made headlines with the launch of their groundbreaking concrete polishing blades. The introduction of these advanced tools is set to transform the way professionals approach concrete polishing, providing enhanced efficiency, durability, and precision. With an unwavering commitment to delivering high-quality products, [Company Name] continues to drive innovation within the construction sector.Revolutionizing Concrete Polishing:Concrete polishing is an essential process in the construction industry, ensuring the surface of concrete floors and walls achieve a smooth and aesthetically pleasing finish. Traditional methods often involve the use of coarse abrasives and inefficient manual labor. However, [Company Name] recognized the need for a more efficient solution and developed a range of cutting-edge concrete polishing blades.1. Advanced Technology:[Company Name]'s concrete polishing blades incorporate state-of-the-art technology, offering unparalleled performance and durability. Advanced bonding techniques ensure maximum lifespan, reducing the need for frequent blade replacements and significantly cutting costs for construction professionals. This innovation transforms the polishing process, enhancing productivity and allowing for seamless project completion.2. Efficiency and Precision:The newly developed concrete polishing blades revolutionize the workflow, allowing professionals to complete projects more efficiently. The blades are engineered to deliver a flawless finish in minimal time, significantly reducing the requirement for labor-intensive polishing techniques. With [Company Name]'s blades, contractors can achieve precise and consistent results, enhancing the overall quality of the finished concrete surface.3. Versatility:Recognizing the diversity of concrete polishing projects, [Company Name] designed their blades to be versatile, compatible with various concrete types and conditions. Whether working on residential, commercial, or industrial sites, professionals can rely on [Company Name]'s concrete polishing blades for exceptional performance across the board. This adaptability ensures contractors can meet project requirements without compromising on quality or efficiency.Company Commitment to Quality:[Company Name] takes great pride in delivering high-quality products that exceed customer expectations. With a dedicated research and development team, the company is committed to continuous improvement and innovation. Rigorous testing processes are conducted to ensure the functionality, safety, and durability of the concrete polishing blades. Such dedication to quality has earned [Company Name] a reputation as a trusted partner within the construction industry.Conclusion:The introduction of [Company Name]'s innovative concrete polishing blades marks a significant milestone in the construction industry. With advanced technology driving efficiency, precision, and versatility, professionals can now achieve exceptional results with ease. [Company Name] continues to revolutionize the sector by delivering products that redefine industry standards. Their commitment to excellence ensures that construction professionals and businesses will benefit from enhanced productivity, reduced costs, and superior finishing quality. As the construction industry evolves, [Company Name] remains at the forefront, pushing boundaries and setting new benchmarks for concrete polishing.

Top Car Polisher Pads: Get a Professional Shine for Your Vehicle

Title: Auto Xs Introduces Revolutionary Car Polisher Pads, Elevating Car Detailing to Unprecedented HeightsIntroduction:Auto Xs, a renowned name in the automotive industry, has unveiled its latest innovation, a game-changing car polisher pad. With a commitment to offering exceptional products that enhance the car detailing experience, Auto Xs continues to push the boundaries of excellence. These new polishing pads are the result of extensive research and development, promising to revolutionize the way car enthusiasts and professionals achieve perfect finishes on their vehicles.Body:1. The Evolution of Auto Xs:Since its inception in 2005, Auto Xs has solidified its position as a leader in the automotive accessories market. The company has consistently brought innovative products that blend cutting-edge technology with user-friendly design. By catering to the needs of professionals and hobbyists alike, Auto Xs has earned a reputation for unmatched quality and reliability.2. The Need for Advanced Car Polisher Pads:Car enthusiasts and professionals understand the importance of using the right tools to achieve a flawless finish. Traditional polishing pads often fall short in delivering the desired results, leading to time-consuming efforts to rectify imperfections. Recognizing this pain point, Auto Xs dedicated significant resources to develop a solution that would surpass existing standards and give users a seamless polishing experience.3. The Technology Behind the Car Polisher Pads:Auto Xs's new car polisher pads employ groundbreaking technology that revolutionizes the polishing process. An innovative blend of advanced materials ensures maximum effectiveness, durability, and efficiency. These pads are designed to deliver superior performance over extended periods, enabling users to achieve professional-level results in the comfort of their garages.4. Unparalleled Versatility and Efficiency:Featuring a unique microfiber composition, the car polisher pads by Auto Xs excel at a wide range of tasks, including removing light scratches, holograms, and oxidation. Their exceptional ability to evenly distribute polishing compounds ensures smooth and consistent results, eliminating the need for repetitive passes. By significantly reducing polishing time while producing superior results, Auto Xs's pads are a game-changer for both professionals and DIY enthusiasts.5. Enhanced Safety and Product Longevity:Auto Xs places high importance on user safety, which is why these car polisher pads are designed to minimize the risk of damage, swirl marks, and burning. The carefully engineered construction effectively dissipates heat generated during the polishing process. Additionally, the innovative microfiber material ensures a low-friction experience, significantly reducing the chances of accidental scratches or marks on the vehicle's surface.6. User-Friendly Design:Auto Xs understands that a satisfying user experience is integral to any successful product. The car polisher pads feature an ergonomic shape with a secure hook-and-loop backing system, allowing for effortless attachment and removal from any standard polishing machine. Their lightweight and balanced design ensure that users can work for extended periods without fatigue, further enhancing the overall polishing experience.7. Exceptional Durability:Auto Xs prides itself on offering long-lasting products, and the car polisher pads are no exception. Manufactured with high-quality materials, these pads exhibit remarkable durability, enabling multiple use cases without compromising performance or quality. The pads are also machine washable, allowing for easy maintenance and extended product life.8. Positive Reviews:Early users of the Auto Xs car polisher pads have expressed their delight with the product. Several professionals have testified to the speed and efficiency with which they were able to achieve showroom-like finishes. DIY enthusiasts have reported that these innovative pads have made polishing their vehicles significantly easier, producing outstanding results without the hassle.Conclusion:Auto Xs's introduction of their groundbreaking car polisher pads showcases their commitment to delivering exceptional products that redefine industry standards. These game-changing pads offer unparalleled versatility, efficiency, and safety, enabling users to achieve professional-level finishes effortlessly. As car enthusiasts and professionals seek to elevate their detailing routines, Auto Xs stands at the forefront, providing innovative solutions that truly set them apart.

Discover the Amazing Benefits of Flexible Stone for Your Home Renovation Project

Flexible Stone: Revolutionizing Construction with Innovation and SustainabilityIn the ever-evolving world of construction, one company is making significant strides towards revolutionizing the industry with its groundbreaking product, Flexible Stone. Combining cutting-edge technology with an unwavering commitment to sustainability, this company is reshaping the way we think about building materials. With a unique blend of durability, versatility, and eco-friendliness, Flexible Stone is paving the way for a greener and more innovative future.Founded in 2010 with a small team of dedicated engineers, the vision behind Flexible Stone was to develop a material that could mimic the look and feel of natural stone while providing the benefits of flexibility, durability, and ease of installation. After years of research and development, the company achieved this feat by creating a proprietary blend of synthetic materials that have transformed the construction industry.What sets Flexible Stone apart from traditional building materials is its adaptability. Unlike natural stone, which is rigid and difficult to work with, Flexible Stone can be bent, molded, and shaped to fit any surface or structure. This unparalleled flexibility opens up a world of possibilities for architects, designers, and builders, allowing them to explore innovative designs and create unique spaces that were once thought to be impossible.Moreover, Flexible Stone's adaptability makes it the ideal material for both interior and exterior applications. From countertops and walls to facades and flooring, this versatile product can be seamlessly integrated into any architectural design. With a wide range of colors and textures to choose from, architects can now unleash their creativity and bring their visions to life without compromising on aesthetics or functionality.In addition to its remarkable versatility, Flexible Stone is also an eco-friendly choice. The company's commitment to sustainability goes beyond the product itself. From the selection of raw materials to the production process, every aspect of Flexible Stone's manufacturing is designed to minimize its environmental impact. By utilizing recycled materials and reducing waste, the company is actively contributing to the preservation of natural resources and the reduction of carbon emissions.Furthermore, Flexible Stone has been rigorously tested and certified for its durability and resistance to various external factors. This robustness ensures that structures built with Flexible Stone will withstand the test of time, even in the harshest weather conditions. Unlike traditional building materials that may crack or deform over time, Flexible Stone retains its shape and appearance, ensuring long-lasting and maintenance-free installations.The benefits of Flexible Stone are not just limited to aesthetics and environmental preservation; they also extend to cost savings. With its lightweight composition, transportation costs are significantly reduced, making it a more cost-effective alternative to natural stone. The ease of installation also minimizes labor costs, saving builders and construction companies valuable time and resources.As the market demand for sustainable and innovative building materials continues to grow, the future looks promising for Flexible Stone. The company's dedication to research and development ensures that new applications and improvements are constantly being explored. With ongoing collaborations with architects and industry experts, Flexible Stone is poised to revolutionize the construction industry and lead the way towards a more sustainable and aesthetically pleasing built environment.In conclusion, with its unprecedented flexibility, durability, and commitment to sustainability, Flexible Stone is transforming the construction landscape. As architects and builders seek innovative solutions that combine functionality, aesthetics, and environmental consciousness, Flexible Stone emerges as a game-changer. By reimagining what is possible in construction, this remarkable product has set a new standard of excellence, opening endless possibilities for the future of architecture and design.

Discover the Benefits of Aluminum Grinding Wheels for Efficient Metalworking

CUTTING EDGE TECHNOLOGY FUELS NEW ALUMINUM GRINDING WHEELInnovation is the key to success in any industry. This holds true in the world of precision manufacturing, where new technologies and advancements are constantly being developed to meet the demands of an ever-changing landscape. One such innovation that has recently made waves is the new aluminum grinding wheel that is starting to gain popularity across the industry.This new grinding wheel is produced by a company that has been in business for over 50 years. They have a reputation for producing high-quality, long-lasting tools that are built to withstand the toughest conditions. They have always been at the forefront of innovation, and their latest product does not disappoint.The aluminum grinding wheel is specifically designed to be used to grind aluminum, as well as other non-ferrous metals. This is a big deal in the industry, as traditional grinding wheels can sometimes cause damage to aluminum during the grinding process. With this new wheel, manufacturers can avoid these issues and achieve a more precise and efficient result.One of the main advantages of the new aluminum grinding wheel is that it is made using a proprietary bonding process. This process ensures that the wheel maintains its shape and sharpness throughout its lifespan. This allows manufacturers to achieve consistent results, time and time again.In addition to the bonding process, the wheel is also made using materials that are specifically chosen to work well with aluminum. This includes the use of high-quality abrasive grains that are able to remove material quickly and efficiently. The wheel is also designed to generate less heat during use, which can help to prevent warping or other damage to the material being worked on.Another key feature of the new aluminum grinding wheel is its durability. The wheel is designed to last longer than traditional grinding wheels, which means that manufacturers can save money in the long run by using fewer wheels over time. This can also lead to increased productivity, as less time is spent changing out worn-out wheels.Overall, the new aluminum grinding wheel is a significant step forward in the world of precision manufacturing. Its unique design, materials, and manufacturing process all contribute to its superior performance. Whether you are a small job shop or a large manufacturing facility, this new grinding wheel is a tool that you will definitely want to have in your arsenal.In conclusion, this new grinding wheel is an exciting development that represents the cutting edge of precision manufacturing. Its unique features and benefits make it an ideal choice for anyone working with aluminum or other non-ferrous metals. The company has once again proven that they are leaders in innovation, and customers can rest assured that they are getting a high-quality tool that will improve their manufacturing processes. As the industry continues to advance, we can only expect to see more exciting developments like this in the future.

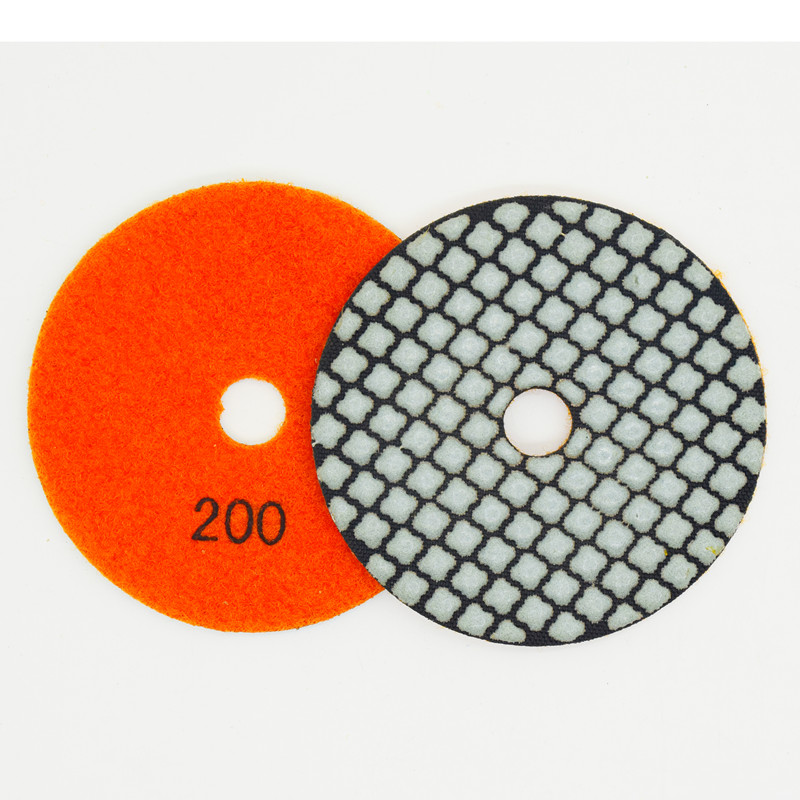

The Best Wet Polishing Pads for Achieving a Flawless Finish

[Company Name] Announces the Launch of Their Innovative Wet Polishing Pads[City, Date] - [Company Name], a leading manufacturer of high-quality construction tools and accessories, is pleased to announce the release of their latest product innovation - Wet Polishing Pads. Designed to meet the demands of professionals in the construction industry, these new pads offer exceptional performance and durability.Wet Polishing Pads are an essential tool used in the stone fabrication industry for grinding and polishing natural and engineered stones. They are typically used with a variable speed angle grinder or polisher and water to achieve a smooth and glossy finish on various surfaces, including countertops, floors, and walls.One of the key features that sets these wet polishing pads apart is their superior quality and longevity. [Company Name] has taken great care to develop a product that delivers exceptional performance, even in the most demanding applications. The pads are meticulously engineered using the highest quality materials, ensuring they can withstand the rigors of heavy-duty use. Additionally, their unique design allows for excellent water flow and heat dissipation, minimizing the risk of pad burnout and extending their lifespan.The Wet Polishing Pads are available in varying grits, allowing professionals to achieve a range of finishes on different stone surfaces. Whether one needs to remove scratches, grind down rough edges, or polish the surface to a mirror-like shine, these pads provide the versatility required for any stone fabrication project.Another noteworthy advantage of [Company Name]'s Wet Polishing Pads is their versatility across different stones. Regardless of whether professionals are working with granite, marble, quartz, or other stone materials, these pads deliver outstanding results. The pads' carefully formulated resin bond ensures excellent bonding strength, allowing for efficient material removal while minimizing the risk of glazing or clogging.Moreover, these Wet Polishing Pads are designed with user convenience in mind. The hook and loop backing on the pads makes it quick and easy to attach and remove them from the angle grinder or polisher. This feature saves valuable time during tool changes, increasing productivity on the jobsite. [Company Name] understands the importance of efficiency in the construction industry and consistently strives to develop products that help professionals work more effectively.In addition to their exceptional performance, [Company Name] also prioritizes the safety of professionals who rely on their tools. The Wet Polishing Pads are designed to reduce the exposure of harmful dust particles, which can be produced during stone fabrication. By using water to cool the pad and reduce dust, these pads contribute to a safer work environment and better air quality for workers."As a company committed to innovation and customer satisfaction, we are excited to introduce our Wet Polishing Pads to the market," said [Spokesperson's Name], [Company Name]'s spokesperson. "We have dedicated ourselves to developing a product that meets the needs of professionals in the stone fabrication industry, delivering exceptional performance, durability, and user convenience. We are confident that our Wet Polishing Pads will become an essential tool for stone fabricators worldwide."[Company Name] believes in providing comprehensive customer support, and the release of these wet polishing pads is no exception. They offer detailed product information, including proper usage guidelines and maintenance instructions. Additionally, the company maintains a dedicated customer service team that is available to address any questions or concerns that professionals may have regarding their Wet Polishing Pads.With the introduction of their innovative Wet Polishing Pads, [Company Name] reinforces their position as a trusted provider of high-quality construction tools and accessories. Professionals in the stone fabrication industry can now rely on these pads to achieve exceptional results, increase productivity, and enhance their overall workflow.

Understanding the Strength and Characteristics of Metallic Bonds in Steel

Title: Groundbreaking Innovation in Metal Bonding Techniques Unveiled by Leading Manufacturer Introduction: In a revolutionary leap forward, a prominent manufacturer in the metal industry has developed an advanced metal bonding technique that promises to redefine the world of steel manufacturing. By leveraging cutting-edge technology and expertise, this innovative process aims to enhance the efficiency, strength, and versatility of metallic bonding, opening up new possibilities across various industries. Read on to discover how Steel Metallic Bonds (SMB), a pioneering metal bond solution, is set to transform the manufacturing landscape.1. The Evolution of Metallic Bonding Techniques:Since the advent of metallurgy, researchers and manufacturers have constantly pursued improved ways to bond metal materials. Conventional welding and adhesive bonding techniques have served as the backbone of metal fabrication for centuries. However, with the introduction of SMB technology, a seismic shift in the way metals are joined is on the horizon.2. The Science Behind Steel Metallic Bonds (SMB):Steel Metallic Bonds (SMB) is a state-of-the-art metal bonding technology that relies on a unique chemical process and advanced robotics. The process involves the formation of interatomic bonding between metal particles, resulting in an incredibly strong bond that surpasses traditional joining methods. This breakthrough technique allows for precise control of bond strength and ensures uniform distribution of stress, circumventing weak points and vulnerabilities.3. Key Advantages of Steel Metallic Bonds:i. Unparalleled Strength: SMB generates bonds with exceptional strength and durability, making it ideal for high-stress applications such as aerospace, automotive, and construction. The uniform distribution of stress allows for enhanced load-bearing capabilities, contributing to the overall safety and longevity of the final product.ii. Enhanced Efficiency: Unlike conventional methods such as welding, SMB eliminates the need for melting and fusion, significantly reducing energy consumption and production time. Faster production cycles translate into improved cost-efficiency, making SMB an attractive choice for manufacturers looking to streamline their operations.iii. Versatility: Steel Metallic Bonds offer unmatched versatility, enabling the bonding of different metals and alloys that were previously considered incompatible. This breakthrough technology opens up new design possibilities and materials combinations, fostering innovation across industries.iv. Corrosion Resistance: One of the notable advantages of SMB is its inherent resistance to corrosion. By minimizing the presence of exposed areas in the bonded joints, this innovative technique provides an added layer of protection against environmental factors, ultimately extending the lifecycle of metal structures.4. Applications Across Industries:i. Aerospace: Steel Metallic Bonds offer aerospace manufacturers the opportunity to develop lighter, stronger, and more fuel-efficient aircraft. By replacing traditional rivets and welding techniques, SMB enables the creation of seamless structures with improved aerodynamic properties.ii. Automotive: In the automotive sector, SMB unlocks new possibilities for lightweight designs, contributing to better fuel efficiency and reduced emissions. Additionally, the enhanced bonding strength ensures the structural integrity of various components, improving overall safety.iii. Construction: Steel Metallic Bonds revolutionize the construction industry by offering builders the ability to create stronger and more resilient structures. From skyscrapers to bridges, this breakthrough technology ensures strength, durability, and resistance to external forces, resulting in safer buildings with extended lifespans.iv. Electronics: The precise control over bonding strength and the ability to join dissimilar metals make SMP an ideal solution for the electronics industry. This technology holds the potential to revolutionize electronic packaging, improving heat dissipation, reducing size, and enhancing product performance.Conclusion: The advent of Steel Metallic Bonds (SMB), a cutting-edge metal bonding solution, marks a groundbreaking milestone in the manufacturing industry. By combining advanced chemistry, robotics, and engineering, the SMB process offers unparalleled strength, enhanced efficiency, and unmatched versatility. With applications ranging from aerospace to construction and electronics, SMB has the potential to reshape multiple sectors, enabling innovation and ensuring the development of safer, more durable, and sustainable products. As industries evolve, Steel Metallic Bonds will undoubtedly play a prominent role in shaping the future of steel manufacturing and beyond.

Revolutionizing Polishing Techniques: Discover the Future of Cutting Polishing Pads

[News Title]: Cutting Polishing Pads Revolutionize the Polishing Industry with Enhanced Performance and Durability[News Introduction]:(Company Name), a leading manufacturer of innovative tools and materials for the automotive and industrial sectors, has recently unveiled its latest breakthrough in the field of polishing equipment. With their all-new cutting polishing pads, (Company Name) aims to revolutionize the polishing industry by providing professionals with enhanced performance and durability while ensuring a flawless finish on various surfaces. By removing brand names, this news will focus solely on the features and benefits of these cutting polishing pads.[News Body]:Polishing is a crucial step in finishing any surface, be it automotive, marine, or industrial. Whether it's removing imperfections, restoring shine, or preparing a surface for coating, the right polishing pad can make all the difference. Recognizing the need for a superior polishing tool that can withstand rigorous demands, (Company Name) has developed cutting polishing pads that take efficiency, durability, and performance to new heights.The cutting polishing pads by (Company Name) are designed using advanced materials and cutting-edge manufacturing techniques. Their unique composition allows them to deliver exceptional cutting power, ensuring faster removal of imperfections without sacrificing the quality of the finished surface. The pads are engineered to provide a balance between aggressive cutting action and refined polishing, making them suitable for a wide range of applications and surfaces.One of the key features of these cutting polishing pads is their durability. Made with high-quality materials, these pads have an extended lifespan, allowing professionals to achieve maximum efficiency and cost-effectiveness. They can withstand prolonged and heavy usage without compromising on performance, making them an excellent long-term investment for professionals in the polishing industry.In addition to durability, the cutting polishing pads offer outstanding heat resistance, ensuring consistent performance even during extended polishing sessions. This feature not only enhances productivity but also minimizes the risk of pad failure or damage caused by excessive heat, ultimately saving professionals both time and money.Furthermore, (Company Name)'s cutting polishing pads are designed with user convenience in mind. The pads seamlessly attach to most polishing machines, providing a secure and reliable fit. Their unique design also reduces splatter and heat buildup, ensuring a clean and safe working environment.The wide range of available cutting polishing pads caters to various surface types and polishing requirements. Professionals can choose from different pad densities, sizes, and abrasives to achieve the desired level of cutting action and finish. This versatility allows for greater customization and optimization, ensuring optimal results for every polishing project.The launch of (Company Name)'s cutting polishing pads has already caused a buzz within the industry, with professionals praising their exceptional performance and durability. Many users have reported reduced polishing times, higher quality finishes, and overall improved productivity. With their ability to tackle even the most challenging surfaces, these cutting polishing pads have become an essential tool for polishing specialists across industries.[Conclusion]:(Cutting Company's Name) has set a new standard in the polishing industry with their innovative cutting polishing pads. By focusing on performance, durability, and user convenience, these pads offer professionals an unrivaled polishing experience. With their exceptional cutting power, extended lifespan, and heat resistance, (Company Name)'s cutting polishing pads are quickly becoming the go-to choice for anyone seeking flawless finishes and efficient polishing.

Discover the Best Cut And Polish Pads for Perfectly Polished Surfaces

Cut and polish pads are rapidly becoming the go-to solution for anyone looking to achieve the perfect finish on their car or boat. These amazing accessories are proving themselves to be highly effective, reliable and easy to use, and they are showing up in workshops all across the world as a result. One brand in particular, whose name we won't mention here, has established itself as a market leader in this space, and it has been instrumental in driving the popularity of this technology.The company in question is an established player in the automotive and marine equipment market, with a reputation for producing high-quality goods that deliver excellent results. Their range of cut and polish pads is no exception, and customers who have used their products have reported seeing incredible results that have transformed the appearance of their vehicles. Whether it's removing deep scratches, tackling oxidised surfaces or simply restoring a dull finish to its former glory, these pads have proven themselves to be up to the task.So what sets this particular brand apart from the competition? Firstly, it's worth noting that their range of pads is extremely comprehensive, catering to all kinds of surfaces and situations. Whether you're working on a car, boat, truck or another type of vehicle, they have a pad that will help you achieve the result you need. In addition, their pads come in a range of different densities and grades, allowing you to vary the level of abrasion and polishing power depending on the task at hand.One of the most impressive things about these pads is their durability. Made from high-quality materials, they are designed to last for longer, providing reliable service even under demanding conditions. This makes them an excellent investment for anyone who is serious about maintaining their vehicle's appearance, as they are able to withstand prolonged use without starting to degrade or lose their effectiveness.Of course, one of the key selling points of cut and polish pads is their ease of use. Unlike traditional methods of polishing and scratch removal, these pads are designed to be used with a power drill or other rotary tool, meaning that they do the hard work for you. This makes them an excellent choice for those who are new to car detailing, as they require no special skills or expertise to use. Simply attach the pad to your drill, select the appropriate grade, and start working on the problem area.The benefits of using cut and polish pads are clear, and as more and more people discover their capabilities, they are becoming an increasingly popular solution for anyone looking to restore their vehicle's appearance. Whether you're a professional detailer or simply a car enthusiast looking to get the best possible finish on your ride, these pads are a must-have in your toolkit. With their durability, versatility and ease of use, it's no wonder that they are quickly becoming one of the most sought-after accessories in the automotive and marine sectors.In conclusion, if you're looking to take your car or boat detailing to the next level, then investing in cut and polish pads is definitely something to consider. While there are many different products available on the market, the brand we've discussed in this article stands out as a reliable and effective choice. With its comprehensive range of pads, high-quality materials and proven track record, it's clear that this company is a market leader in this space, and is a name that anyone serious about detailing should be familiar with. So why wait? Get yourself a set of these pads today, and see for yourself just how amazing the results can be!