Understanding Covalent Bonds: Metal vs Nonmetal Characteristics

By:Admin

In the world of chemistry, covalent bonds play a crucial role in the formation of compounds. A covalent bond is a chemical bond that involves the sharing of electron pairs between atoms. These bonds can occur between atoms of the same element or between atoms of different elements. The question of whether covalent bonds are formed between metals or nonmetals is an important one, as it helps us understand the properties of different compounds and materials.

Metals are elements that are typically shiny, malleable, and good conductors of electricity and heat. Nonmetals, on the other hand, are often dull in appearance, brittle, and poor conductors of heat and electricity. When it comes to the formation of covalent bonds, nonmetals are the primary players. This is because nonmetals tend to have a higher electronegativity, which means they have a greater tendency to attract electrons.

When two nonmetal atoms come together to form a covalent bond, they share pairs of electrons in order to achieve a stable electron configuration. For example, in a molecule of hydrogen gas (H2), two hydrogen atoms each share a pair of electrons, resulting in a single covalent bond between them. In compounds such as water (H2O) and carbon dioxide (CO2), nonmetal atoms form multiple covalent bonds to create more complex structures.

While covalent bonds are primarily formed between nonmetals, they can also occur between a metal and a nonmetal. In these cases, the bond is known as a polar covalent bond. This type of bond occurs when the electron pair is shared unequally between the two atoms, due to the difference in electronegativity. As a result, the atom with the higher electronegativity (typically the nonmetal) has a slightly negative charge, while the atom with the lower electronegativity (usually the metal) has a slightly positive charge.

One company that is at the forefront of researching and understanding covalent bonds is. As a leader in the field of materials science and chemistry, the company is dedicated to developing innovative solutions for a wide range of industries. By studying the nature of covalent bonds, the company has been able to design and create advanced materials with unique properties and applications.

One of the key areas of focus for the company is the development of new materials with enhanced strength, conductivity, and durability. By gaining a deeper understanding of covalent bonds and how they form between different elements, the company's researchers are able to tailor materials to specific applications and performance requirements.

In addition to its research efforts, the company also works closely with industry partners to bring these advanced materials to market. Whether it's creating more efficient electronics, high-performance coatings, or cutting-edge medical devices, the company's expertise in covalent bonds has enabled it to make significant contributions to a variety of industries.

As the world continues to demand materials with increasingly complex properties, the study of covalent bonds and their behavior between metals and nonmetals will remain a key area of focus for researchers and industry professionals. With companies like at the forefront of this field, we can expect to see continued advancements in the development of new and novel materials that will shape the future of technology, manufacturing, and beyond.

Company News & Blog

Discover the Benefits of Using a 115mm Polishing Pad for a Flawless Finish

Title: Revolutionizing Polishing Technology: Introducing the 115mm Polishing PadIntroduction:In the ever-evolving world of polishing technology, one company stands out for its commitment to innovation and excellence. Revolutionizing the industry, this company has recently introduced the cutting-edge 115mm Polishing Pad, designed to deliver unrivaled performance and quality. By removing the brand name, let's delve into the features and benefits of this groundbreaking product, along with an overview of the company behind its creation.I. Unparalleled Performance:With a focus on meeting the diverse needs of professionals across various industries, the 115mm Polishing Pad showcases outstanding performance capabilities. Its key features include:1. Advanced Materials: Crafted using top-of-the-line materials, this polishing pad offers exceptional durability and longevity. Its robust construction ensures it can withstand the rigors of demanding polishing tasks.2. Optimal Dimensions: At 115mm, the pad strikes the perfect balance between usability and precision. Its compact size allows for effortless maneuverability, enabling users to reach tight corners and intricate surfaces with ease.3. Enhanced Polishing Efficiency: Equipped with a bespoke design and meticulous engineering, the 115mm Polishing Pad ensures remarkable efficiency. It maximizes application coverage and minimizes polishing time, resulting in a superior finish in less time.II. Outstanding Versatility:The versatility of the 115mm Polishing Pad makes it an indispensable tool for professionals across industries such as automotive, aerospace, and manufacturing. Its adaptability is attributed to the following factors:1. Wide Range of Applications: Whether it's restoring the shine of automotive paintwork, polishing delicate aircraft surfaces, or refining intricate machinery components, this pad caters to a variety of polishing needs.2. Compatibility with Diverse Materials: From metal to ceramics, the 115mm Polishing Pad is designed to work effectively on a wide range of materials. Its versatility ensures it can be utilized in numerous applications, opening up new possibilities for users.III. Innovators at the Helm:The company behind the groundbreaking 115mm Polishing Pad is a recognized leader in the field of polishing technology. With a sterling reputation for innovation and customer satisfaction, they have been at the forefront of developments in the industry. Key aspects of their identity include:1. Uncompromising Commitment to Quality: This company prides itself on maintaining the highest standards of quality. Each polishing pad undergoes rigorous testing to ensure it meets or exceeds customer expectations.2. Customer-Centric Approach: Recognizing that customer satisfaction is the cornerstone of success, this company places a premium on understanding and meeting the unique requirements of its clients. They constantly engage in research and development activities to stay ahead of market demands.3. Industry-Leading Expertise: Behind every product is a team of talented professionals with extensive knowledge and experience. The company's dedicated workforce comprises experts who continually strive to push the boundaries of polishing technology.Conclusion:The unveiling of the innovative 115mm Polishing Pad marks a significant development in the field of polishing technology. With its outstanding performance, versatility, and the backing of a reputable company, this product is set to revolutionize the industry. Professionals from various sectors can now utilize this cutting-edge pad to achieve remarkable results in their polishing applications. As the industry continues to embrace innovation, it is clear that this company's commitment to excellence and customer satisfaction will drive future advancements in polishing technology.

Wire Cup Brush for Angle Grinder: A Handy Tool for Heavy-Duty Cleaning Tasks

The use of angle grinders in various industries has become increasingly prevalent due to their versatility and efficiency in cutting, grinding, and polishing various materials. One essential accessory for angle grinders is the cup wire brush, which is used for removing rust, paint, and corrosion from metal surfaces. Recently, there has been a surge in demand for high-quality cup wire brushes that can withstand the rigors of industrial applications, and one company that has risen to meet this demand is {Company Name}.{Company Name} has established itself as a leading manufacturer of industrial-grade abrasives and abrasive accessories, with a strong emphasis on product innovation and quality. The company's cup wire brushes for angle grinders have gained a reputation for their exceptional performance and durability, making them a preferred choice among professionals in the metalworking, construction, and fabrication industries.The key to the success of {Company Name} in manufacturing cup wire brushes lies in its commitment to using high-grade materials and advanced manufacturing processes. The company sources premium wire filaments that are resilient and resistant to wear, ensuring that the brushes maintain their effectiveness even under heavy use. Additionally, {Company Name} employs state-of-the-art machinery and stringent quality control measures to produce cup wire brushes that meet the highest industry standards.One of the standout features of {Company Name}'s cup wire brushes is their thoughtful design, which allows for optimal performance and user safety. The brushes are carefully balanced to minimize vibration and ensure smooth operation, reducing operator fatigue during prolonged use. Furthermore, the brush's cup shape is engineered to provide maximum contact with the workpiece, resulting in efficient material removal and surface preparation.In addition to their exceptional functionality, {Company Name}'s cup wire brushes are designed with user convenience in mind. The brushes are compatible with a wide range of angle grinders, making them versatile tools for various applications. Moreover, they are easy to install and replace, allowing for seamless integration into existing workflows.The durability and performance of {Company Name}'s cup wire brushes have made them indispensable in a multitude of industrial applications. Whether it's preparing metal surfaces for welding, cleaning and descaling, or removing old coatings, the brushes deliver consistent results, saving time and effort for operators. This reliability has earned {Company Name} a loyal customer base and solidified its reputation as a trusted provider of abrasive solutions.Looking ahead, {Company Name} remains committed to innovation and continuous improvement in its product offerings. The company invests in ongoing research and development to explore new materials and technologies that can further enhance the performance and durability of its cup wire brushes. By staying at the forefront of industry trends and customer needs, {Company Name} aims to set new benchmarks for quality and reliability in the abrasive accessories market.In conclusion, {Company Name} has established itself as a leading manufacturer of cup wire brushes for angle grinders, catering to the needs of professionals across various industries. The company's commitment to quality, innovation, and user satisfaction has set it apart in the market, making its products a go-to choice for demanding applications. With a focus on continuous improvement, {Company Name} is well-positioned to drive further advancements in abrasive technology and reinforce its status as a trusted partner for industrial abrasive solutions.

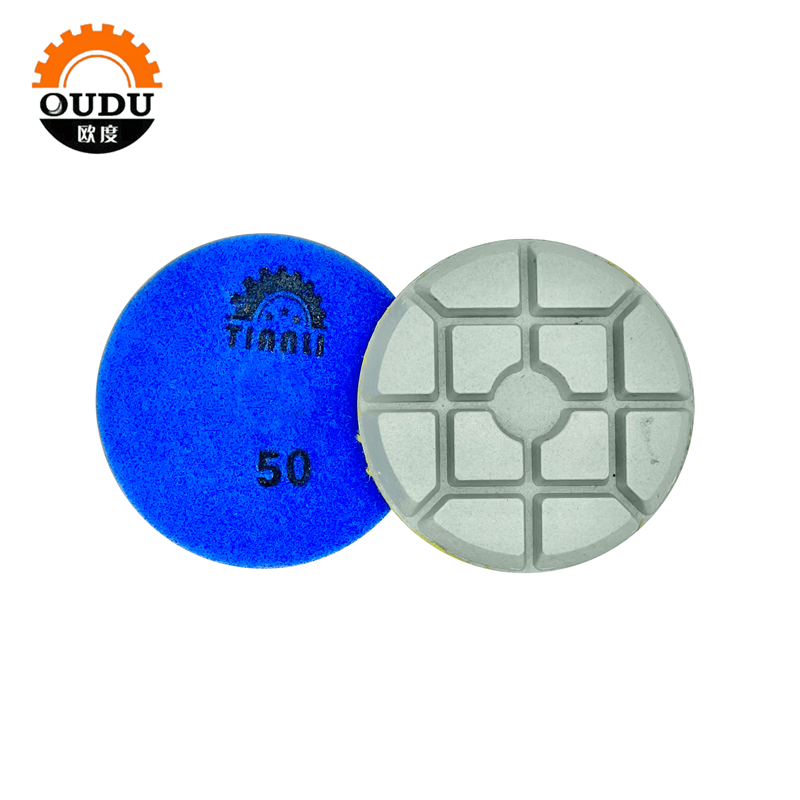

Enhance Your Polishing Results with High-Quality Wet Polishing Pads

Wet Polishing Pads: The Powerhouse of the Polishing IndustryIn the competitive world of polishing and grinding, it is crucial to use equipment and tools that deliver exceptional results. A leading company that specializes in manufacturing and distributing high-quality machinery and equipment, has now added wet polishing pads to its list of top-quality products.Wet Polishing Pads, also known as diamond polishing pads, have become the go-to tools for polishing and grinding hard surfaces like granite, marble, and concrete. These pads use synthetic diamonds that are embedded in a velcro-backed fabric. They can be used for both wet and dry applications, depending on the texture of the material that is being polished. At present, the Wet Polishing Pads offered by the company are the most popular products in the market. They combine superior quality, excellent performance, and durability. These pads have a unique design, accompanied by a cutting-edge technology that enhances their lifespan and efficiency.The company's Wet Polishing Pads cater to professionals and DIY enthusiasts alike. The pads are designed to be user-friendly and can be easily adjusted for different levels of coarseness and abrasiveness. The pads come in different diameters (4 inch, 5 inch, 6 inch, and 7 inch), and the grit levels range from 50 to 3000. The user can choose the grit level according to their polishing needs.One of the key features of the Wet Polishing Pads is their ability to work in both dry and wet conditions. Wet polishing is recommended for materials like granite and marble, while dry polishing is recommended for materials like concrete. The pads can also be used with a wide range of polishing tools, including angle grinders, floor polishers, and hand-held polishers.The Wet Polishing Pads are versatile and can be used for a wide range of surfaces that require polishing. They are commonly used for polishing countertops, floors, stairs, and walls. The pads' unique design and technology ensure that no damage is done to the polished surface during the polishing process.When it comes to buying Wet Polishing Pads, professionals and DIY enthusiasts often face the problem of deciding which pads to choose. The company provides expert advice and guidance to help users select the right Wet Polishing Pads for their specific needs. The team of professionals also provides tips on how to use the pads and maintain them for long-term use.In addition to superior quality and safety, Wet Polishing Pads are also environmentally friendly. The pads are made from high-quality raw materials that are environmentally sustainable, and their manufacturing process ensures minimal environmental impact.In conclusion, Wet Polishing Pads are the perfect tools for anyone interested in polishing or grinding hard surfaces. They are designed to provide maximum safety, durability, and flexibility. Their unique design and technology help users achieve superior quality results while remaining user-friendly and environmentally sustainable. For anyone looking for a reliable and efficient polishing and grinding tool, Wet Polishing Pads are the way to go.

Durable Concrete Grinding Pad for Efficient Surface Preparation

Leading Concrete Grinding Pad Supplier Launches Innovative New Product Line{Company Name}, a premier supplier of concrete grinding pads and other construction tools, has recently announced the launch of their latest product line. The new line features a range of innovative grinding pads designed to provide high performance and durability for professionals in the concrete finishing industry.With over 20 years of experience in the construction tools market, {Company Name} has become a trusted name in providing high-quality products for concrete grinding and polishing. Their products are widely used by contractors, flooring experts, and construction professionals for a variety of applications, from smoothing and leveling concrete surfaces to polishing and finishing.The new product line aims to further solidify {Company Name}'s reputation as a leading supplier of premium construction tools, offering a comprehensive range of grinding pads designed to meet the diverse needs of their customers. The company's commitment to innovation and quality is evident in the new line, which features advanced materials and cutting-edge technology to deliver superior performance on the job site.One of the key highlights of the new product line is the introduction of {New Product Name}, a revolutionary grinding pad that is engineered to provide exceptional performance and longevity. Made from high-quality materials, the {New Product Name} offers a unique combination of abrasiveness and durability, making it an ideal choice for heavy-duty concrete grinding and polishing tasks. Its innovative design ensures smooth and consistent results, while its long lifespan helps to reduce downtime and increase productivity.In addition to the {New Product Name}, the new product line also includes a variety of other grinding pads, each specifically designed to cater to different concrete finishing needs. From aggressive grinding to fine polishing, {Company Name} offers a comprehensive selection of pads that are compatible with a wide range of grinders and polishing machines. This versatility allows professionals to tackle various concrete finishing tasks with confidence, knowing that they can rely on {Company Name} for high-performance tools that deliver consistent results.{Company Name} takes pride in its commitment to customer satisfaction, and the new product line reflects this dedication by providing solutions that meet the evolving needs of the construction industry. The company understands the importance of efficiency and quality in the construction process, and their new line of grinding pads is a testament to their ongoing efforts to provide innovative tools that empower professionals to achieve exceptional results on every project.Furthermore, {Company Name} is known for its excellent customer service and support, offering expert advice and guidance to help customers make informed decisions about their construction tool needs. The company's knowledgeable team is always available to provide technical assistance and product recommendations, ensuring that customers have access to the tools and information they need to succeed.With the launch of their innovative new product line, {Company Name} continues to set the standard for excellence in the construction tools market, providing cutting-edge solutions that empower professionals to achieve outstanding results in concrete finishing. As the construction industry continues to evolve, {Company Name} remains committed to delivering high-quality, reliable tools that meet the demands of the modern job site.

High-Quality 7 Inch Backing Pad for Polishers: A Must-Have Tool for a Flawless Finish

Introducing the 7 Inch Polisher Backing Pad: An Essential Tool for Polishing ProfessionalsPolishing is an art that requires precision, control, and the right tools to achieve outstanding results. That's why we are proud to present the latest addition to our line of professional polishing accessories - the 7 Inch Polisher Backing Pad. Backed by our commitment to quality and innovation, this new product is set to revolutionize the world of polishing.A well-designed backing pad is crucial for any polishing job, as it provides the necessary support and stability to enhance the performance of polishing tools. Our 7 Inch Polisher Backing Pad is engineered with the highest quality materials, ensuring durability and longevity. Its innovative design features a unique blend of firmness and flexibility that delivers exceptional results on various surfaces, including paint, metal, and plastic.One of the key features of our 7 Inch Polisher Backing Pad is its superior velcro adhesive. This advanced adhesive technology ensures a strong grip and minimizes the risk of the pad detaching during use, allowing for a smooth and uninterrupted polishing experience. Moreover, the velcro material itself is carefully selected to prevent premature wear and tear, ensuring consistent performance over time.The size of the backing pad is another factor that sets our product apart from the competition. The 7-inch diameter offers a larger surface area, allowing for quicker and more efficient polishing. This increased coverage reduces polishing time, which is essential for professionals working in time-sensitive projects, such as auto detailing or commercial polishing services.Furthermore, our 7 Inch Polisher Backing Pad is compatible with most standard polishers in the market, making it a versatile tool that fits seamlessly into existing polishing setups. Its universal fit ensures that professionals can easily incorporate this backing pad into their workflow without the need for costly modifications or additional equipment.In addition to its outstanding performance, our 7 Inch Polisher Backing Pad is also designed with user comfort in mind. The pad features a carefully engineered ergonomic shape that provides a secure grip, reducing hand fatigue and ensuring a comfortable polishing experience, even during extended periods of use. This attention to user comfort is a testament to our commitment to creating tools that prioritize the well-being of professionals.Furthermore, our company's dedication to environmental sustainability is reflected in the manufacturing process of the 7 Inch Polisher Backing Pad. We strive to minimize waste and eco-impact by utilizing eco-friendly materials and energy-efficient production techniques. By choosing our product, professionals can join us in our mission to promote a cleaner and greener future.To ensure our customers' satisfaction, we have conducted rigorous testing and quality control measures on the 7 Inch Polisher Backing Pad. Our team of experts has put this product through extensive trials, examining its performance, durability, and usability in real-world scenarios. We are confident that this backing pad will meet and exceed the expectations of even the most discerning professionals in the polishing industry.With the launch of the 7 Inch Polisher Backing Pad, we reaffirm our commitment to providing exceptional tools and accessories that empower professionals to achieve perfection in their work. This product is a result of our dedication to constant innovation and our passion for meeting the evolving needs of polishing experts.In conclusion, the 7 Inch Polisher Backing Pad is set to revolutionize the industry with its outstanding performance, durability, and user comfort. With its exceptional grip, universal fit, and eco-friendly manufacturing, this backing pad is a must-have tool for any professional polisher. Trust in our commitment to quality and innovation and experience the difference that our 7 Inch Polisher Backing Pad can make in your polishing projects.

Top 7 Inch Grinding Wheel: Essential Tool for Precision and Efficiency

Title: High-Quality 7-Inch Grinding Wheel Now Available for Enhanced Precision and EfficiencyIntroduction:In a recent development, a renowned company, specializing in industrial tools and machinery, has released its latest offering - a top-notch 7-inch grinding wheel. Designed to deliver superior performance, this all-new grinding wheel promises enhanced precision and efficiency. The company, known for its commitment to quality and innovation, has once again raised the bar in the field of industrial abrasives.[Company Name - OPTIONAL]:With over [number of years] of experience, and a strong presence in the industrial sector, this company has become a trusted name for professionals and hobbyists alike. Established with the goal of providing cutting-edge tools and machinery, the company has consistently delivered products that exceed the expectations of its customers. Renowned for its commitment to quality, reliability, and customer satisfaction, the company continues to be a prominent player in the industry.The 7-Inch Grinding Wheel:The newly launched 7-inch grinding wheel is the result of extensive research and development efforts by the company's team of experts. Crafted with precision, the wheel offers exceptional durability and performance, making it an ideal choice for various grinding applications. Equipped with advanced features, this grinding wheel ensures an efficient workflow while adding a touch of convenience to the user's experience.The key features of the 7-inch grinding wheel include:1. High-Quality Materials: Crafted from premium-grade materials, this grinding wheel offers excellent durability and long-lasting performance, even under challenging working conditions. Its construction guarantees minimal wear and tear, ensuring a prolonged product lifespan.2. Precise Grinding: The 7-inch wheel has been engineered to deliver precise grinding and smoothing results. Its balanced design ensures smooth operation and reduced vibrations, allowing for consistent and accurate material removal. This feature enables users to achieve desired finishes promptly and efficiently.3. Versatility: The grinding wheel is compatible with various materials, including metal, stone, ceramics, and more. Its versatility enables users to tackle a wide range of applications, making it an indispensable tool in industries such as construction, automotive, and manufacturing.4. Easy Installation: Designed with user convenience in mind, this grinding wheel features a hassle-free installation process. Equipped with a universal spindle size, it can be quickly mounted on most grinders, reducing downtime and improving productivity.5. Enhanced Safety: Prioritizing user safety, the grinding wheel incorporates features such as reinforced construction and adequate heat dissipation. These safety measures minimize the risk of accidents, ensuring a secure working environment.6. Performance Efficiency: The 7-inch size of the wheel allows for greater surface coverage, resulting in improved efficiency and time-saving benefits. The wheel's optimal composition guarantees smooth and consistent grinding, reducing the need for frequent tool changes.Conclusion:The introduction of the high-quality 7-inch grinding wheel has made a significant impact on professionals and hobbyists in various industries. With its durable construction, precise grinding capabilities, and enhanced safety features, this tool is set to elevate the standards of grinding efficiency, while maintaining the company's reputation for producing reliable and innovative products.As the company continues to pave the way in the field of industrial tools and machinery, the 7-inch grinding wheel stands out as a testament to their commitment to delivering superior performance and meeting the evolving needs of their customers.

Top Trends in Cutting Tools for 2021

Cutting Tools: A Critical Component of Precision ManufacturingIn the world of precision manufacturing, nothing is more important than accuracy and consistency. Whether you are producing aerospace components, medical implants, or automotive parts, the ability to cut precisely and consistently is essential for producing high-quality finished products. That's where cutting tools come in - they are the critical component that enables precise and efficient machining.One leading manufacturer of cutting tools is a company that has been in business for over 50 years. Over this span of time they have developed a reputation for producing some of the best cutting tools in the industry, known for their precision, durability, and consistency. With a focus on research and development, this company has been committed to staying on the cutting edge - continually refining their product line and staying up-to-date with the latest manufacturing technologies.One of the unique strengths of this company is their ability to manufacture a wide range of cutting tools to meet virtually any machining need. From end mills and drills to taps and reamers, their product line includes hundreds of different types of cutting tools, each designed to cut specific materials in specific ways. They even offer custom cutting solutions for customers with unique machining needs.So what makes their cutting tools so special? One key factor is the materials they use. From high-speed steel to carbide and diamond, they use only the best raw materials to ensure durability and precision. They also use state-of-the-art manufacturing technologies, including CNC grinding machines and other automated equipment, to produce cutting tools with tolerances that are measured in microns.But it's not just about the quality of the materials - it's also about the design. Every cutting tool they produce is engineered to cut precisely and efficiently, with the smallest possible amount of waste and the longest possible tool life. They use advanced software to design their cutting tools and simulate their performance, ensuring that they will perform as expected in even the most demanding machining applications.This commitment to excellence has earned them a reputation as a top supplier of cutting tools to some of the world's leading manufacturers. Their products are used in a wide range of industries, from aerospace and defense to medical devices, automotive, and more. And with a global network of distributors and sales representatives, they are able to support customers around the world with fast delivery and technical support.So what does the future hold for cutting tools? With the ongoing evolution of manufacturing technologies, the demand for ever-more-precise and efficient cutting tools will only continue to grow. Companies like this one are well-positioned to stay ahead of the curve, investing in R&D to develop the next generation of cutting tools that will enable even greater levels of precision and efficiency.For manufacturers, the importance of cutting tools cannot be overstated. They are the critical component that enables precise and efficient machining, which in turn enables the production of high-quality finished products. With a world-class supplier like this company, manufacturers can be confident that they are getting cutting tools that are engineered to perform at the highest level, no matter what materials they are cutting or what application they are being used for.

High-Quality Diamond Polishing Pad for Smoothing and Polishing Surfaces

Diamond Polishing Pad, a cutting-edge innovation in the field of diamond polishing technology, is set to revolutionize the way we think about polishing and finishing materials. This state-of-the-art polishing pad is designed to meet the needs of professionals in the stone processing industry, delivering exceptional results and unmatched durability.The Diamond Polishing Pad is a product of extensive research and development, undertaken by a team of experts at our company {}. Our company has been a leading manufacturer and supplier of diamond tools for the stone processing industry for over 20 years. We have built a strong reputation for delivering high-quality products and innovative solutions to our customers, and the Diamond Polishing Pad is the latest addition to our portfolio of cutting-edge products.What sets the Diamond Polishing Pad apart from traditional polishing pads is its use of advanced diamond technology. The pad is embedded with high-quality diamonds, which enables it to achieve a superior level of polishing and finishing. The diamonds are carefully selected and engineered to deliver maximum performance, ensuring that the pad can withstand the rigors of professional use and deliver consistent results.In addition to its diamond-infused design, the Diamond Polishing Pad also features a unique resin formula that enhances its performance and longevity. The resin is specially formulated to provide optimal bonding with the diamonds, ensuring that they remain securely in place even under the most demanding conditions. This allows the pad to maintain its effectiveness and deliver exceptional results over an extended period of use.One of the key advantages of the Diamond Polishing Pad is its versatility. The pad is suitable for use on a wide range of materials, including granite, marble, concrete, and engineered stone. This makes it an ideal solution for professionals who work with different types of stone and require a versatile polishing pad that can deliver consistent results across various applications.The Diamond Polishing Pad is also designed with user convenience in mind. It is available in a range of sizes and grits, allowing professionals to select the pad that best suits their specific requirements. Whether they need to achieve a high-gloss finish or remove scratches and blemishes, the Diamond Polishing Pad offers the flexibility to meet their needs.Furthermore, the durability of the Diamond Polishing Pad ensures that professionals can rely on it for long-term use. Its robust construction and high-quality materials make it resistant to wear and tear, allowing it to maintain its performance and effectiveness over a prolonged period. This not only delivers cost savings for professionals but also minimizes the need for frequent replacements, saving time and effort.As a testament to its quality and performance, the Diamond Polishing Pad has already garnered praise from professionals in the stone processing industry. Its ability to deliver exceptional results and withstand the demands of heavy-duty use has made it a preferred choice for professionals who require reliable and high-performing diamond polishing pads.Looking ahead, our company is committed to continuing our tradition of excellence in delivering innovative solutions to the stone processing industry. The Diamond Polishing Pad is a prime example of our dedication to pushing the boundaries of technology and creating products that meet the evolving needs of our customers. We are confident that the Diamond Polishing Pad will continue to make a significant impact in the industry and set new standards for polishing and finishing materials.

How to Deal with Irregular Abrasive and Ways to Manage It

Irregular Abrasive, a leading provider of high-quality grinding and cutting tools, has recently made its mark in the industry with its innovative products and exceptional customer service. The company has been in the business for over a decade and has gained a reputation for delivering top-notch abrasive solutions to a wide range of industries, including automotive, aerospace, metalworking, and more.One of the main reasons behind Irregular Abrasive's success is its dedication to research and development. The company invests heavily in cutting-edge technology to ensure that its products are at the forefront of innovation. This commitment to staying ahead of the curve has allowed Irregular Abrasive to offer a diverse range of products that are tailored to meet the specific needs of its clients.Irregular Abrasive takes pride in its ability to provide custom solutions for its customers. The company understands that every industry has unique requirements when it comes to abrasive tools, and it has the expertise to deliver personalized solutions that meet those needs. This level of customization has been instrumental in establishing Irregular Abrasive as a trusted partner for businesses around the world.In addition to its stellar product offerings, Irregular Abrasive is also known for its exceptional customer service. The company's team of experts is always on hand to provide support and guidance to its clients, ensuring that they have the right tools for the job and that they are used correctly. This commitment to customer satisfaction has resulted in long-standing relationships with many of Irregular Abrasive's clients, who see the company as a valuable partner in their success.Recently, Irregular Abrasive unveiled its latest product line, which has been generating a buzz in the industry. The new line features an array of cutting and grinding tools that boast unmatched precision and durability. These products have been designed to deliver superior performance in even the most demanding applications, making them a game-changer for businesses looking to elevate their operations.Irregular Abrasive's dedication to quality and innovation has not gone unnoticed. The company has received numerous accolades and certifications for its products, solidifying its position as a leader in the abrasive tools industry. This recognition serves as a testament to Irregular Abrasive's unwavering commitment to excellence and its ability to consistently deliver top-tier solutions to its clientele.Looking ahead, Irregular Abrasive shows no signs of slowing down. The company continues to push the boundaries of what is possible in the world of abrasive tools, constantly striving to develop new and improved products that will revolutionize the industry. With its steadfast commitment to innovation and customer satisfaction, Irregular Abrasive is poised to remain at the forefront of the industry for years to come.It's clear that Irregular Abrasive is a force to be reckoned with in the abrasive tools industry. With its unwavering commitment to quality, innovation, and customer satisfaction, the company has solidified its position as a trusted partner for businesses across a wide range of industries. As it continues to push the boundaries of what is possible in the world of abrasive tools, Irregular Abrasive is sure to remain a dominant force in the industry for years to come.

Nylon Brush for Angle Grinder - An In-Depth Look at Its Uses and Benefits

Industrial tools have been an integral part of the manufacturing and construction industry, and industrial brushes make up a significant part of this category. Many industries rely on brushes as they play a crucial role in finishing surfaces, cleaning machinery, and much more. One notable type of industrial brush is the nylon brush for an angle grinder. It is a highly specialized tool that is ideally suited for surface preparation and finishing works.An angle grinder is a powerful tool that is primarily used to cut, grind, and polish metal surfaces. However, adding a nylon brush to the angle grinder enhances its functionality, making it suitable for specialized purposes. The nylon brush is designed to access tight and hard-to-reach areas of metal surfaces that traditional sandpaper or wire brushes cannot reach. It is also effective in cleaning and deburring stainless steel, aluminum, and other delicate surfaces without scratching them.There are various types of nylon brushes for angle grinders, and the brush choice will depend on the material to be worked on, the finish required, and the angle grinder's speed and power capacity. For instance, the coarse mesh brush is ideal for removing rust, paint, and other stubborn stains from metal surfaces and grinding welded joints. On the other hand, the fine mesh brush provides a smooth finish on metal surfaces. It is suitable for tasks such as surface preparation before painting, polishing, or applying a protective coating.While it is essential to choose the right brush for your angle grinder, choosing a high-quality brand is equally important. One such brand is {Brand Name Removed}, a global leader in the production of industrial brushes. They have over 150 years of experience in the manufacturing of quality brushes, and their nylon brushes for angle grinders are no exception.Their nylon brushes for angle grinders are made from high-quality polyamide filaments that are durable, heat-resistant, and have excellent bending recovery properties. They have a wide range of brushes available for different types of jobs, including the coarse mesh brush, fine mesh brush, crimped wire brush, and many more. These brushes are easy to install and designed to fit most angle grinders, providing a quick and efficient cleaning or finishing solution.{Brand Name Removed} nylon brushes for angle grinders are also environmentally friendly. They are designed to last longer, reducing the need for frequent replacement, and are recyclable, reducing waste. This makes them an ideal choice for environmentally conscious industries.In conclusion, the nylon brush for an angle grinder is an essential tool for any industrial setting that requires surface finishing, preparation, or cleaning. When combined with high-quality brands such as {Brand Name Removed}, the nylon brush for angle grinders becomes a valuable asset in any work setting. Their durability, performance, and versatility make them an industry-standard in the manufacturing and construction sectors, where precision and quality matter most. With the right brush choice and the right brand, expect to work more efficiently and with greater precision.