Powerful and Versatile Angle Grinder Machine: Unlocking a World of Possibilities

By:Admin

Introduction:

In a breakthrough development, a global leader in industrial machinery has unveiled the latest addition to its portfolio of metalworking tools – the all-new Angle Grinder Machine. This cutting-edge innovation promises to revolutionize the metal fabrication industry and comes from the renowned company {}, renowned for its commitment to excellence and continuous product advancement.

Paragraph 1:

The Angle Grinder Machine, a result of extensive research and development, offers an unparalleled level of versatility and precision in metalworking. Manufactured to the highest industry standards, it is designed to meet the evolving needs of professional metalworkers, from fabrication to restoration projects. By combining power, agility, and ergonomic design, this cutting-edge tool is poised to set new benchmarks in the industry and establish itself as an indispensable asset.

Paragraph 2:

The Angle Grinder Machine stands out for its state-of-the-art features that enable efficient and seamless metalworking operations. Equipped with a high-performance electric motor, it delivers exceptional power and speed, geared towards handling various materials with ease. Whether cutting, grinding, polishing, or buffing, this machine ensures precision and consistency in every task, thereby minimizing production time and enhancing overall productivity.

Paragraph 3:

Safety is of paramount importance in any metalworking undertaking, and the Angle Grinder Machine is fully equipped to address this concern. With advanced safety mechanisms, such as integrated braking systems and protective guards, user safety is prioritized, preventing potential accidents and injuries. Furthermore, ergonomic design features, such as non-slip handles and adjustable components, contribute to user comfort during prolonged operations, ensuring enhanced control and maneuverability.

Paragraph 4:

The Angle Grinder Machine takes pride in its user-friendly interface, featuring intuitive controls and digital displays that provide real-time feedback. This allows operators to easily adjust settings, monitor performance, and fine-tune their processes according to specific requirements. Additionally, the machine's durability and reliability are further enhanced by its robust construction, ensuring its ability to withstand the rigorous demands of industrial metalworking environments.

Paragraph 5:

The Angle Grinder Machine is not just a testament to technological brilliance; it also aligns with a global push towards sustainable practices. Built with energy-efficient components, it minimizes power consumption without compromising performance. This eco-conscious approach contributes to a greener future by reducing carbon footprints and promoting responsible resource management within the metal fabrication industry.

Paragraph 6:

Recognizing the importance of continuous improvement, the company {} has invested in comprehensive customer support services. The Angle Grinder Machine is backed by a dedicated team of technical experts who provide training, guidance, and assistance, ensuring that operators can maximize the machine's capabilities and achieve optimal results. This commitment to customer satisfaction strengthens the company's reputation as an industry leader in providing cutting-edge solutions.

Conclusion:

With the introduction of the Angle Grinder Machine, {} is once again at the forefront of pushing boundaries in industrial machinery. This innovative tool brings together power, precision, and safety, offering metalworkers a transformative experience in their daily operations. By combining cutting-edge technology with sustainable practices and exceptional customer support, the Angle Grinder Machine has the potential to reshape the metalworking landscape and inspire new possibilities for the industry.

Company News & Blog

Master the Art of Floor Polishing: Unveiling the Ultimate Polishing Pad

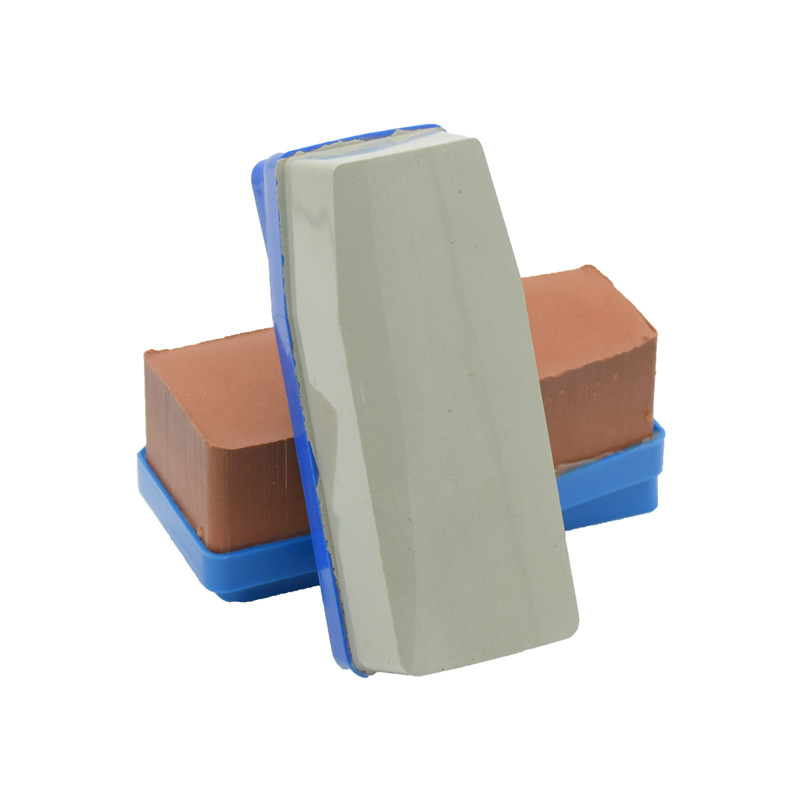

release.Floor Polishing Pad: The Ultimate Solution for Polishing and Cleaning FloorsFloor polishing is a crucial process that every homeowner or business owner should consider to maintain the beauty and durability of their floors. Proper polishing enables you to remove scratches, scuffs, stains, and other stubborn dirt from your floors, leaving them sparkling clean and smooth. However, you need to have the right tool for the job, and that's where the Floor Polishing Pad comes in.The Floor Polishing Pad is a revolutionary product that has taken the floor polishing market by storm. It's a high-quality, durable pad that's designed to provide exceptional polishing and cleaning results for various floor surfaces such as hardwood, marble, concrete, terrazzo, and more. The pad is made from premium materials that are designed to withstand constant use and high pressure, making it the perfect tool for both commercial and residential use.One of the outstanding features of the Floor Polishing Pad is its versatility. It's designed to fit a wide range of floor polishing machines, making it an ideal accessory for professionals and DIY enthusiasts alike. The pad is available in various sizes and shapes to fit different floor polishing machines, allowing you to achieve the desired results with ease.Another advantage of the Floor Polishing Pad is its excellent performance. The pad is designed to deliver outstanding results, leaving your floors looking clean, shiny, and well-polished. The pad is made using cutting-edge technology, ensuring that every strand of fiber is perfectly aligned to ensure optimal performance. The pad is also designed with a unique diamond pattern that ensures uniform distribution of pressure and heat, preventing any damage to the floor surface.The Floor Polishing Pad is also designed to be environmentally friendly. It's made using non-toxic, biodegradable materials, making it safe for use in both residential and commercial settings. The pad doesn't contain any harmful chemicals that may harm the environment or pose a risk to human health. Moreover, it's easy to clean and maintain, ensuring that it remains in perfect condition for long.In conclusion, the Floor Polishing Pad is the ultimate solution for anyone looking to achieve exceptional results when polishing and cleaning their floors. Whether you're a professional or a DIY enthusiast, this pad provides the perfect tool for any floor polishing application. Its versatility, outstanding performance, and environmental friendliness make it a top choice for anyone looking to maintain their floors' beauty and durability. So, why wait? Get your Floor Polishing Pad today and experience the difference.

New Study Reveals Surprising Results for Industry Leaders in Latest SEO Trends

Introducing Durable and Versatile Sanding Pads for Professionals and DIY EnthusiastsIn an industry where quality and effectiveness matter, one company is revolutionizing the way professionals and DIY enthusiasts approach sanding tasks. Enter Backer Pads, a game-changer in the field of sanding equipment. Let us take a closer look at this innovative product and how it is transforming the way people work.Backer Pads, developed by a leading manufacturer, are becoming the go-to choice for professionals and DIY enthusiasts. Renowned for their durability and versatility, these sanding pads deliver exceptional performance to users across various industries, including woodworking, metalworking, automotive, and more. With a focus on manufacturing high-quality products, this company has developed a reputation for innovation, reliability, and customer satisfaction.One of the key features of Backer Pads is their exceptional durability. Crafted from premium materials, these pads are designed to withstand rigorous use, ensuring that they won't wear out even during the most challenging sanding tasks. This enhanced durability makes them ideal for professionals who often work with heavy machinery and intense pressure. Whether it's polishing, sanding, or grinding, Backer Pads are built to last, allowing users to complete their projects with ease and confidence.Versatility is another hallmark of Backer Pads, making them a must-have tool for both professionals and DIY enthusiasts. Designed to fit a wide range of sanding machines, these pads effortlessly adapt to various sanding tasks. The company offers a diverse range of grit levels, catering to different project requirements. Whether users need a coarser grit for rough sanding or a finer grit for a polished finish, Backer Pads have them covered. This versatility enhances efficiency and reduces the need to invest in multiple sanding tools, allowing individuals to complete their projects more effectively.Backer Pads also excel in providing consistent and uniform results. With their advanced design and precision-engineered construction, these sanding pads deliver a smooth and even sanding experience. This ensures that surfaces are adequately prepared for painting, varnishing, or other finishing touches. Moreover, the consistent results enhance the overall quality of the project and save valuable time and effort for users.Safety is also at the forefront of Backer Pads' design philosophy. With built-in safety features, these pads provide users with peace of mind while working on their projects. The pads are designed to maintain excellent grip and stability, reducing the risk of accidents and injuries. Additionally, they are manufactured using environmentally friendly materials, reflecting the company's commitment to sustainability and responsible manufacturing practices.The superior performance, versatility, and durability of Backer Pads have garnered widespread recognition from professionals across industries. Many woodworking professionals, metalworkers, and automotive enthusiasts have reported increased productivity and efficiency after incorporating these sanding pads into their toolkit. The positive reviews and testimonials further solidify Backer Pads' reputation as a must-have accessory for anyone involved in sanding tasks.In conclusion, Backer Pads are a game-changer in the field of sanding equipment. From their exceptional durability to their versatility and consistent results, these pads have become a preferred choice for both professionals and DIY enthusiasts. With a commitment to quality and innovation, the company behind Backer Pads continues to redefine the sanding experience, revolutionizing the way people work. As professionals and hobbyists embark on their next sanding project, it is clear that Backer Pads will continue to be the go-to choice for delivering outstanding results.

Discover the Benefits of Wire Brush Grinding Wheels

Title: Industry Leader Introduces Innovative Wire Brush Grinding Wheel to Enhance Metal Surface PreparationIntroduction:[Company Name], a renowned industry leader in manufacturing high-quality metalworking tools and equipment, is proud to announce the launch of their latest product innovation — the Wire Brush Grinding Wheel. Designed to revolutionize metal surface preparation, this cutting-edge tool offers exceptional performance, durability, and efficiency, catering to professionals across various industries.Blending state-of-the-art technology with years of expertise, [Company Name] has successfully developed a Wire Brush Grinding Wheel that surpasses existing market offerings in terms of quality and functionality. This innovative tool is set to enable professionals to achieve precise and effective metal surface preparation, ensuring excellent results in a wide range of applications such as welding, painting, and coating.Product Features:The Wire Brush Grinding Wheel features a unique combination of high-grade wire bristles and an advanced grinding wheel. The wire bristles are skillfully designed and evenly spaced, ensuring efficient removal of rust, scale, and other contaminants from metal surfaces. The grinding wheel, made of premium abrasives, ensures smooth and precise grinding, resulting in a flawless surface ready for subsequent processes.Moreover, the Wire Brush Grinding Wheel incorporates an ergonomic design that allows for comfortable and safe handling during extended periods of use. The tool's lightweight construction reduces operator fatigue and increases overall productivity.Industry-leading professionals who have tested the Wire Brush Grinding Wheel express their satisfaction with its superior performance and durability. Unlike traditional abrasive wheels that wear out quickly, this innovative tool maintains its grinding power and wire bristle efficiency over extended periods, reducing downtime and enabling longer operational life.Applications:The Wire Brush Grinding Wheel caters to diverse industries, including manufacturing, construction, automotive, and metal fabrication. Professionals engaged in surface preparation, metal cleaning, and restoration processes can benefit greatly from this tool's exceptional capabilities.In metal manufacturing, the Wire Brush Grinding Wheel proves invaluable in surface conditioning, deburring, and weld seam cleaning. It easily removes rust, paint, and scale from surfaces, preparing them for subsequent processes like painting, welding, or coating.For automotive enthusiasts and mechanics, the Wire Brush Grinding Wheel is a game-changer. From removing stubborn surface contaminants to restoring old parts, this tool ensures a smooth and clean surface ready for paint or further refurbishment.Furthermore, contractors involved in construction projects can rely on the Wire Brush Grinding Wheel for efficient surface preparation of metal structures, ensuring optimal adherence for protective coatings.Conclusion:[Company Name] continues to establish itself as an industry leader by introducing groundbreaking products to enhance metalworking processes. The Wire Brush Grinding Wheel is a testament to the company's commitment to providing professionals with innovative and reliable tools that deliver outstanding results.Featuring an exceptional combination of wire bristles and cutting-edge grinding wheel technology, this new product offers unmatched performance, durability, and efficiency. [Company Name] has once again raised the bar in metal surface preparation, catering to a wide range of industries such as manufacturing, construction, automotive, and metal fabrication.Professionals can now embrace the Wire Brush Grinding Wheel as their go-to tool for achieving flawless metal surfaces, ensuring a seamless transition to subsequent processes such as welding, painting, and coating. With this latest innovation, [Company Name] reaffirms its status as a pioneer in the metalworking industry, consistently delivering premium solutions that meet the evolving needs of professionals worldwide.

Powerful and Versatile Angle Grinder Machine: Unlocking a World of Possibilities

Title: Innovation in Metalworking: Introducing the Versatile Angle Grinder MachineIntroduction:In a breakthrough development, a global leader in industrial machinery has unveiled the latest addition to its portfolio of metalworking tools – the all-new Angle Grinder Machine. This cutting-edge innovation promises to revolutionize the metal fabrication industry and comes from the renowned company {}, renowned for its commitment to excellence and continuous product advancement.Paragraph 1:The Angle Grinder Machine, a result of extensive research and development, offers an unparalleled level of versatility and precision in metalworking. Manufactured to the highest industry standards, it is designed to meet the evolving needs of professional metalworkers, from fabrication to restoration projects. By combining power, agility, and ergonomic design, this cutting-edge tool is poised to set new benchmarks in the industry and establish itself as an indispensable asset.Paragraph 2:The Angle Grinder Machine stands out for its state-of-the-art features that enable efficient and seamless metalworking operations. Equipped with a high-performance electric motor, it delivers exceptional power and speed, geared towards handling various materials with ease. Whether cutting, grinding, polishing, or buffing, this machine ensures precision and consistency in every task, thereby minimizing production time and enhancing overall productivity.Paragraph 3:Safety is of paramount importance in any metalworking undertaking, and the Angle Grinder Machine is fully equipped to address this concern. With advanced safety mechanisms, such as integrated braking systems and protective guards, user safety is prioritized, preventing potential accidents and injuries. Furthermore, ergonomic design features, such as non-slip handles and adjustable components, contribute to user comfort during prolonged operations, ensuring enhanced control and maneuverability.Paragraph 4:The Angle Grinder Machine takes pride in its user-friendly interface, featuring intuitive controls and digital displays that provide real-time feedback. This allows operators to easily adjust settings, monitor performance, and fine-tune their processes according to specific requirements. Additionally, the machine's durability and reliability are further enhanced by its robust construction, ensuring its ability to withstand the rigorous demands of industrial metalworking environments.Paragraph 5:The Angle Grinder Machine is not just a testament to technological brilliance; it also aligns with a global push towards sustainable practices. Built with energy-efficient components, it minimizes power consumption without compromising performance. This eco-conscious approach contributes to a greener future by reducing carbon footprints and promoting responsible resource management within the metal fabrication industry.Paragraph 6:Recognizing the importance of continuous improvement, the company {} has invested in comprehensive customer support services. The Angle Grinder Machine is backed by a dedicated team of technical experts who provide training, guidance, and assistance, ensuring that operators can maximize the machine's capabilities and achieve optimal results. This commitment to customer satisfaction strengthens the company's reputation as an industry leader in providing cutting-edge solutions.Conclusion:With the introduction of the Angle Grinder Machine, {} is once again at the forefront of pushing boundaries in industrial machinery. This innovative tool brings together power, precision, and safety, offering metalworkers a transformative experience in their daily operations. By combining cutting-edge technology with sustainable practices and exceptional customer support, the Angle Grinder Machine has the potential to reshape the metalworking landscape and inspire new possibilities for the industry.

Enhance Your Polishing Results with High-Quality Wet Polishing Pads

Wet Polishing Pads: The Powerhouse of the Polishing IndustryIn the competitive world of polishing and grinding, it is crucial to use equipment and tools that deliver exceptional results. A leading company that specializes in manufacturing and distributing high-quality machinery and equipment, has now added wet polishing pads to its list of top-quality products.Wet Polishing Pads, also known as diamond polishing pads, have become the go-to tools for polishing and grinding hard surfaces like granite, marble, and concrete. These pads use synthetic diamonds that are embedded in a velcro-backed fabric. They can be used for both wet and dry applications, depending on the texture of the material that is being polished. At present, the Wet Polishing Pads offered by the company are the most popular products in the market. They combine superior quality, excellent performance, and durability. These pads have a unique design, accompanied by a cutting-edge technology that enhances their lifespan and efficiency.The company's Wet Polishing Pads cater to professionals and DIY enthusiasts alike. The pads are designed to be user-friendly and can be easily adjusted for different levels of coarseness and abrasiveness. The pads come in different diameters (4 inch, 5 inch, 6 inch, and 7 inch), and the grit levels range from 50 to 3000. The user can choose the grit level according to their polishing needs.One of the key features of the Wet Polishing Pads is their ability to work in both dry and wet conditions. Wet polishing is recommended for materials like granite and marble, while dry polishing is recommended for materials like concrete. The pads can also be used with a wide range of polishing tools, including angle grinders, floor polishers, and hand-held polishers.The Wet Polishing Pads are versatile and can be used for a wide range of surfaces that require polishing. They are commonly used for polishing countertops, floors, stairs, and walls. The pads' unique design and technology ensure that no damage is done to the polished surface during the polishing process.When it comes to buying Wet Polishing Pads, professionals and DIY enthusiasts often face the problem of deciding which pads to choose. The company provides expert advice and guidance to help users select the right Wet Polishing Pads for their specific needs. The team of professionals also provides tips on how to use the pads and maintain them for long-term use.In addition to superior quality and safety, Wet Polishing Pads are also environmentally friendly. The pads are made from high-quality raw materials that are environmentally sustainable, and their manufacturing process ensures minimal environmental impact.In conclusion, Wet Polishing Pads are the perfect tools for anyone interested in polishing or grinding hard surfaces. They are designed to provide maximum safety, durability, and flexibility. Their unique design and technology help users achieve superior quality results while remaining user-friendly and environmentally sustainable. For anyone looking for a reliable and efficient polishing and grinding tool, Wet Polishing Pads are the way to go.

Highly Efficient Wet Polisher for Granite Surfaces: Boost Your Polishing Projects!

As the construction industry continues to grow, the demand for high-quality stone fabrication and installation services also increases. Today, advanced firms use state-of-the-art equipment, such as the wet polisher, to promote a more efficient and precise stone polishing. One brand that stands out among these polishing machines is the Granite Wet Polisher.The Granite Wet Polisher is a powerful and cost-effective tool that transforms rough stone into a polished surface. It offers unparalleled benefits as it allows users to polish stones in a faster and more efficient way than traditional methods. With its excellent features, the Granite Wet Polisher has garnered positive reviews from its users, who attest to its exceptional performance and longevity.But beyond the machine's specifications, the story of Granite Wet Polisher's manufacturing process is just as fascinating.The company behind the Granite Wet Polisher prides itself on bringing together talented engineers and designers to create innovative and cutting-edge products. They use their collective experience in the industry to craft machines that give users improved performance and reliability.Apart from this dedication to quality, the company also ensures that their machines meet environmental standards. The Granite Wet Polisher is made with materials that are both durable and eco-friendly, making it one of the few machines that do not harm the environment.The company has also invested in state-of-the-art facilities to ensure that their products are manufactured efficiently. They regularly upgrade their production line to keep up with the competition, and their team of experts always strives to bring the latest technological innovations to their machines.As the construction industry moves towards digitization, the Granite Wet Polisher has become the go-to choice for stone fabrication businesses looking to improve their efficiency and quality of work. This is because the machine is easy to use, comes with useful features, and is compact enough to fit in any workshop.Aside from its technical specifications, the company's customer service is also top-notch. They understand that repair or maintenance work is a part of any machine's life, and that's why they offer a comprehensive warranty and repair service. Even if you're using an old Granite Wet Polisher, the company's team of technicians can diagnose and fix any issue.In conclusion, the Granite Wet Polisher is more than just a technical machine that performs a specific function. It represents the culmination of the company's dedication to quality, environment, and innovation. With the Granite Wet Polisher, stone fabrication businesses can increase their productivity, reduce costs, and improve the quality of their work.

Highly Effective Abrasive Brush for Drill: A Valuable Tool for Various Applications

Title: Versatile Abrasive Brush for Drilling: A Game-Changer in Surface PreparationIntroduction: In the world of construction and surface preparation, having the right tools is paramount to achieving quality results efficiently. A versatile and powerful tool that has been gaining popularity among professionals and DIY enthusiasts alike is the abrasive brush for drills. This innovative tool has revolutionized the way surfaces are prepared, transforming time-consuming and labor-intensive projects into quick and efficient tasks. In this article, we will explore the multifaceted uses and benefits of this abrasive brush, along with a glimpse into the company behind its creation.1. Versatile Applications:The abrasive brush for drills provides a wide range of applications, making it an indispensable tool for various industries. From metal fabrication to woodworking, this brush excels in removing paint, rust, corrosion, and other stubborn residues from surfaces. It can be effectively used on wood, metal, or concrete, making it a versatile companion for any project. Whether it's reviving an old piece of furniture or restoring a weathered outdoor fixture, this brush delivers impeccable results.2. Advanced Technology:The secret behind the efficiency of the abrasive brush lies in its advanced technology. The bristles of the brush are crafted with strong and durable abrasive fibers that are capable of removing even the toughest deposits. These fibers are securely attached to a high-speed drill, allowing for aggressive yet precise brushing action. The innovative design ensures that the brush remains safe to use, preventing any damage to the material being worked on, while providing exceptional performance.3. Time-Saving Solution:One of the major advantages of using an abrasive brush for drills is the significant reduction in project time. Traditional methods of surface preparation often involve manual scraping or the use of chemicals, which can be time-consuming and labor-intensive. With this brush, however, the process becomes remarkably efficient. The powerful rotation of the drill combined with the brush's aggressive cleaning action enables users to accomplish tasks in a fraction of the time, without compromising quality.4. Health and Safety:Promoting health and safety is a vital aspect of any construction or home improvement project. Therefore, it is essential to choose tools that prioritize the well-being of users. By utilizing the abrasive brush for drills, individuals reduce their exposure to potentially harmful chemical agents typically associated with surface preparation. This tool offers a safer and more environment-friendly alternative, greatly benefiting both professionals and DIY enthusiasts.5. The Company behind the Innovation:Behind this groundbreaking technology is a renowned industry leader specializing in providing high-quality and reliable tools for professionals across various sectors. XYZ Company, a global provider of innovative solutions, has developed the abrasive brush for drills to address the escalating demands of surface preparation projects. With a commitment to excellence and customer satisfaction, XYZ Company has established itself as a trusted name in the industry.Conclusion:The versatile abrasive brush for drills has emerged as a game-changer in surface preparation, offering a powerful and efficient solution to a wide range of applications. With its advanced technology and time-saving capabilities, this tool has transformed arduous tasks into manageable projects. By prioritizing health and safety, the abrasive brush is a superior choice for professionals and DIY enthusiasts alike. Backed by a leading company like XYZ Company, this innovation epitomizes the future of surface preparation, promising exceptional results and unparalleled performance.

A Guide to Aluminum Backer Pads for Polishing and Grinding

Title: Cutting-Edge Aluminum Backer Pad Revolutionizes Polishing Techniques in the Construction IndustryIntroduction:In an ever-evolving construction industry, technological advancements play a crucial role in improving efficiency and effectiveness. One such innovation gaining significant attention is the groundbreaking Aluminum Backer Pad, developed by a renowned industry leader. This state-of-the-art product is set to redefine polishing techniques, offering a host of benefits that will undoubtedly propel the construction industry into a new era of excellence.Product Overview:The Aluminum Backer Pad is a cutting-edge tool designed specifically for polishing and grinding applications in the construction and renovation sectors. Made from high-quality aluminum, this innovative product demonstrates exceptional durability and versatility, making it an essential addition to any construction professional's toolkit.Unmatched Durability:Aluminum, renowned for its strength and resilience, forms the foundation of this revolutionary backer pad. Unlike traditional backer pads made of plastic or rubber, this aluminum variant offers superior longevity, withstanding rigorous use and extended periods of polishing without succumbing to wear and tear. This unparalleled durability ensures a longer lifespan, significantly reducing replacement costs for construction companies and individual contractors alike.Optimal Balance and Stability:The Aluminum Backer Pad's ingenious design incorporates a high level of balance and stability, providing an enhanced polishing experience. Its unique geometric structure enables efficient distribution of pressure across the polishing surface, resulting in a smoother and more even finish. This eliminates the risk of uneven polishing and facilitates the creation of flawlessly polished surfaces, ideal for a variety of applications, including concrete, natural stone, and ceramics.Enhanced Versatility:This aluminum-based backer pad offers exceptional versatility, adapting to various polishing methods and surfaces. With its universal fitting system, construction professionals can seamlessly attach the pad to most commonly used polishing machines, eliminating the need for multiple backer pads for different projects. This adaptability saves time and effort, while ensuring consistent and exceptional results across diverse applications.Efficient Heat Dissipation:Heat generation during polishing processes can lead to equipment failure and reduced efficiency. The Aluminum Backer Pad addresses this challenge by incorporating advanced heat dissipation technology. This innovative design allows for efficient air circulation, preventing the buildup of excess heat. By minimizing heating issues, the backer pad enables longer and uninterrupted periods of polishing, enhancing productivity and reducing project completion times.Eco-Friendly Advantages:In line with growing environmental concerns, the Aluminum Backer Pad supports sustainable practices within the construction industry. Its aluminum composition is fully recyclable, reducing waste and promoting a greener approach to construction projects. By investing in this eco-friendly product, construction companies can bolster their commitment to environmental responsibility, appealing to both clients and regulatory bodies.Conclusion:The introduction of the Aluminum Backer Pad signifies a revolutionary leap in polishing techniques within the construction industry. Its exceptional durability, balance, and versatility offer construction professionals the ability to achieve flawless results consistently. Furthermore, its efficient heat dissipation and eco-friendly composition highlight the commitment to excellence and sustainability that drive the company's development of cutting-edge tools and equipment.As the construction industry continues to evolve, the Aluminum Backer Pad stands poised to become an indispensable asset for countless polishing applications. With its host of benefits, this groundbreaking product promises to streamline operations, expedite project completion, and elevate the overall quality of construction and renovation projects.

Top 7 Inch Grinding Wheel: Essential Tool for Precision and Efficiency

Title: High-Quality 7-Inch Grinding Wheel Now Available for Enhanced Precision and EfficiencyIntroduction:In a recent development, a renowned company, specializing in industrial tools and machinery, has released its latest offering - a top-notch 7-inch grinding wheel. Designed to deliver superior performance, this all-new grinding wheel promises enhanced precision and efficiency. The company, known for its commitment to quality and innovation, has once again raised the bar in the field of industrial abrasives.[Company Name - OPTIONAL]:With over [number of years] of experience, and a strong presence in the industrial sector, this company has become a trusted name for professionals and hobbyists alike. Established with the goal of providing cutting-edge tools and machinery, the company has consistently delivered products that exceed the expectations of its customers. Renowned for its commitment to quality, reliability, and customer satisfaction, the company continues to be a prominent player in the industry.The 7-Inch Grinding Wheel:The newly launched 7-inch grinding wheel is the result of extensive research and development efforts by the company's team of experts. Crafted with precision, the wheel offers exceptional durability and performance, making it an ideal choice for various grinding applications. Equipped with advanced features, this grinding wheel ensures an efficient workflow while adding a touch of convenience to the user's experience.The key features of the 7-inch grinding wheel include:1. High-Quality Materials: Crafted from premium-grade materials, this grinding wheel offers excellent durability and long-lasting performance, even under challenging working conditions. Its construction guarantees minimal wear and tear, ensuring a prolonged product lifespan.2. Precise Grinding: The 7-inch wheel has been engineered to deliver precise grinding and smoothing results. Its balanced design ensures smooth operation and reduced vibrations, allowing for consistent and accurate material removal. This feature enables users to achieve desired finishes promptly and efficiently.3. Versatility: The grinding wheel is compatible with various materials, including metal, stone, ceramics, and more. Its versatility enables users to tackle a wide range of applications, making it an indispensable tool in industries such as construction, automotive, and manufacturing.4. Easy Installation: Designed with user convenience in mind, this grinding wheel features a hassle-free installation process. Equipped with a universal spindle size, it can be quickly mounted on most grinders, reducing downtime and improving productivity.5. Enhanced Safety: Prioritizing user safety, the grinding wheel incorporates features such as reinforced construction and adequate heat dissipation. These safety measures minimize the risk of accidents, ensuring a secure working environment.6. Performance Efficiency: The 7-inch size of the wheel allows for greater surface coverage, resulting in improved efficiency and time-saving benefits. The wheel's optimal composition guarantees smooth and consistent grinding, reducing the need for frequent tool changes.Conclusion:The introduction of the high-quality 7-inch grinding wheel has made a significant impact on professionals and hobbyists in various industries. With its durable construction, precise grinding capabilities, and enhanced safety features, this tool is set to elevate the standards of grinding efficiency, while maintaining the company's reputation for producing reliable and innovative products.As the company continues to pave the way in the field of industrial tools and machinery, the 7-inch grinding wheel stands out as a testament to their commitment to delivering superior performance and meeting the evolving needs of their customers.

Understanding the Role of Covalent Bonds in Metal or Nonmetal Elements

Title: Understanding Covalent Bonds: Bridging Metals and NonmetalsIntroduction:In the realm of chemistry, the concept of covalent bonds plays a crucial role in explaining the behavior of elements and compounds. The formation of covalent bonds between metals and nonmetals is particularly intriguing, as it allows for the creation of unique materials with diverse properties. This article will delve into the world of covalent bonds, elucidating their significance and exploring their applications across various industries.Understanding Covalent Bonds:Covalent bonding occurs when two atoms share electrons to achieve a stable electron configuration. These bonds are prevalent between nonmetals, as they typically have higher electronegativity values, the tendency to attract electrons, compared to metals. The sharing of electrons allows both atoms to attain a complete outer electron shell, resulting in a stable molecule.Importance of Covalent Bonds:Covalent bonds between metals and nonmetals yield compounds known as metalloids or semiconductors. These materials possess properties that are intermediate between conductors (metals) and insulators (nonmetals), making them integral to various industries ranging from electronics to energy storage.Applications in Semiconductor Industry:Semiconductors are fundamental components in the electronics sector, driving technological advancements. Covalent bonding involving metals and nonmetals enables the creation of semiconducting materials such as silicon (Si) and germanium (Ge). These elements possess unique properties that allow them to be used in microchips, transistors, and solar panels.Silicon, a widely used semiconductor, demonstrates the remarkable potential of covalent bonds in enabling technological progress. Its ability to both conduct and insulate electricity makes it a primary material for integrated circuits. Moreover, the covalent bonding between silicon atoms facilitates the formation of a crystalline lattice, providing stability and efficient electron flow, thereby enhancing the performance of electronic devices.Covalent Bonding in Chemical Industry:The chemical industry extensively relies on covalent bonds to synthesize compounds with desirable properties. By combining metals and nonmetals, chemists can manipulate covalent bonds to modify the reactivity and stability of substances.Organometallic compounds, for instance, are widely used in catalysis. By incorporating metals into organic molecules via covalent bonding, catalysts with remarkable efficiency and selectivity can be developed. Such catalysts play a crucial role in the production of pharmaceuticals, plastics, and other chemical products, making them vital for sustainable industrial processes.Exploring Covalent Bonds in Materials Science:Materials science utilizes covalent bonds to engineer materials with superior strength, electrical conductivity, and thermal properties. Carbon, a nonmetal, forms covalent bonds with itself to create an extensive array of materials, including diamond, graphite, and carbon nanotubes.Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, epitomizes the extraordinary potential of covalent bonds in material design. Its unrivaled strength, elasticity, and electrical conductivity make it a promising candidate for advancements in electronics, energy storage, and even medicine.Advancements in Covalent Bond Research:Research surrounding covalent bonds is rapidly evolving, with scientists exploring new frontiers in materials science and catalysis. Understanding the intricacies of covalent bonding allows for the development of novel materials with enhanced properties and improved industrial processes.In conclusion, covalent bonds play a pivotal role in bridging metals and nonmetals, giving rise to diverse materials with unique properties. The applications of covalent bonding across various industries highlight its significance in shaping technological advancements and promoting sustainable practices. As research continues, we can expect exciting breakthroughs that further harness the potential of covalent bonds for the betterment of society.