Metal Atom Forms Bonds With Nonmetal Element

By:Admin

In a groundbreaking development in the field of chemistry, researchers at {} have discovered a new way for metal atoms to bond with nonmetal atoms, potentially opening up a wide range of possibilities for the creation of new materials and compounds. This breakthrough has the potential to revolutionize various industries, including pharmaceuticals, electronics, and materials science.

{} is a renowned research institution that has been at the forefront of scientific innovation for decades. With state-of-the-art facilities and a team of world-class researchers, the institution has made significant contributions to various scientific fields.

The recent discovery revolves around the bonding of metal atoms with nonmetal atoms, a process that was previously thought to be extremely challenging to achieve. By utilizing advanced computational modeling and experimental techniques, the researchers at {} were able to demonstrate a novel approach to creating these chemical bonds, which has the potential to greatly expand the toolbox of chemists and materials scientists.

Traditionally, chemical bonds between metals and nonmetals are known to be highly polarized, with the metal atom donating electrons to the nonmetal atom. This results in the formation of ionic compounds, which often exhibit distinct properties such as high melting points and electrical conductivity. However, the new approach discovered by the researchers at {} allows for the formation of covalent bonds between metal and nonmetal atoms, representing a significant departure from conventional wisdom in the field of chemistry.

The implications of this discovery are vast. Covalent bonds between metal and nonmetal atoms have the potential to give rise to new classes of materials with unique properties and applications. For example, the development of novel semiconductor materials with enhanced electronic properties could revolutionize the field of electronics, leading to the creation of more efficient and powerful electronic devices.

Furthermore, this breakthrough has the potential to impact the field of catalysis, as the ability to form covalent bonds between metal and nonmetal atoms opens up new possibilities for the design of catalysts with unprecedented reactivity and selectivity. This could have far-reaching implications for a wide range of industrial processes, from the production of fuels and chemicals to environmental remediation.

The potential applications of this discovery also extend to the field of pharmaceuticals. The ability to form covalent bonds between metal and nonmetal atoms could lead to the development of new classes of drug molecules with enhanced potency and selectivity, potentially leading to breakthroughs in the treatment of various diseases.

The researchers at {} are currently exploring the practical applications of this discovery, working closely with industry partners to translate their findings into real-world technologies. Through collaborations with companies in the electronics, materials, and pharmaceutical industries, the institution aims to harness the potential of covalent metal-nonmetal bonds to develop innovative solutions that address pressing societal and technological challenges.

As the research team at {} continues to delve deeper into the potential applications of their discovery, the scientific community eagerly anticipates the unveiling of new breakthroughs and innovations that could reshape various industries. This latest development represents a testament to the institution's commitment to pushing the boundaries of scientific knowledge and driving meaningful advancements that have the potential to make a lasting impact on the world.

Company News & Blog

Everything You Need to Know About Grinding Wheel Hubs

Grinding Wheel Hub Unveils Innovative Solutions for Manufacturing IndustryGrinding Wheel Hub, a leading manufacturer of cutting-edge grinding wheel solutions, is proud to introduce its latest innovations for the manufacturing industry. With a commitment to delivering high-quality products and exceptional customer service, Grinding Wheel Hub has become a trusted partner for companies across various sectors.Founded in [year], Grinding Wheel Hub has been at the forefront of developing innovative grinding wheel solutions that improve efficiency and productivity in the manufacturing process. The company's dedication to research and development has enabled it to create cutting-edge products that address the evolving needs of the industry.One of Grinding Wheel Hub's flagship products is its [product name], which has gained widespread recognition for its exceptional performance. The [product name] is designed to meet the demands of high-speed precision grinding, offering superior cutting ability and extended wheel life. With a focus on durability and consistency, this product has become a go-to choice for manufacturers looking to optimize their grinding operations.In addition to its advanced product line, Grinding Wheel Hub is also known for its customer-centric approach. The company works closely with clients to understand their specific requirements and develop customized solutions that meet their needs. Whether it's designing a new grinding wheel for a specialized application or providing technical support, Grinding Wheel Hub is committed to delivering value to its customers."We take pride in our ability to innovate and collaborate with our clients to create solutions that drive success in the manufacturing industry," said [Spokesperson Name], CEO of Grinding Wheel Hub. "Our focus on quality, reliability, and performance has positioned us as a trusted partner for companies seeking cutting-edge grinding wheel solutions."Beyond its products and services, Grinding Wheel Hub is also dedicated to sustainability and environmental stewardship. The company has implemented various initiatives to reduce waste and minimize its carbon footprint, aligning with the growing emphasis on sustainable manufacturing practices.As part of its ongoing commitment to innovation, Grinding Wheel Hub continues to invest in research and development to stay ahead of industry trends. The company's state-of-the-art manufacturing facilities and testing laboratories enable it to uphold the highest standards of quality and performance.With an unwavering dedication to excellence, Grinding Wheel Hub has earned a strong reputation in the manufacturing industry. The company's ability to provide reliable, cutting-edge solutions has established it as a leader in the market, catering to diverse needs across various sectors.Looking ahead, Grinding Wheel Hub is poised to further expand its product line and capabilities to meet the evolving needs of the manufacturing industry. The company's commitment to innovation, quality, and customer satisfaction sets the stage for continued success and leadership in the market.As the manufacturing industry continues to evolve, Grinding Wheel Hub remains at the forefront, empowering companies with advanced grinding wheel solutions that drive efficiency, productivity, and success. With its unwavering commitment to excellence, the company is well-positioned to shape the future of manufacturing with its innovative products and customer-centric approach.

150mm Polishing Pads: Everything You Need to Know

article about the introduction of the new polishing pads.The world of automotive detailing and restoration is always evolving with new products being introduced on a regular basis. In recent times, the introduction of new polishing pads has been creating waves in the industry.One such revolutionary product is the 150mm Polishing Pads, which has created a buzz in the industry due to its excellent performance and efficiency in achieving a perfect finish on any vehicle surface. As a result, industry professionals, enthusiasts, and detailers are eagerly waiting to get their hands on the new product.The 150mm Polishing Pads have been developed by a leading global manufacturer that specializes in producing advanced cleaning and restoration tools for the automotive industry. The new polishing pads are the result of extensive research and development, as well as feedback from industry experts and customers.These polishing pads have been designed to achieve superior performance and improve efficiency in the detailing process. The 150mm Polishing Pads come in a range of options, including different grades of abrasives, foam densities, and colors, to cater to a wide variety of detailing applications.The 150mm Polishing Pads are made from high-quality foam that is durable and reliable enough to withstand the most demanding and intricate polishing and detailing work. The new pads come with a unique design that ensures even distribution of heat, allowing for more control and efficient use of the polishing compound.According to the company's spokesperson, "We are excited to introduce our latest product, the 150mm Polishing Pads, to the market. The new pads are designed to provide a better experience and efficiency in detailing and restoration work. With improved durability and performance, the 150mm Polishing Pads are an excellent addition to any detailing tool kit."The company's commitment to innovation and customer satisfaction is evident in the development of the 150mm Polishing Pads. The company prides itself on producing products that are not only efficient and durable but also affordable, making them accessible to enthusiasts and professionals alike.The 150mm Polishing Pads are suitable for use on all types of surfaces, including paint, glass, chrome, and plastic, making them an ideal choice for detailers, automotive restorers, and enthusiasts alike. The pads come in a range of grades, from cutting and polishing to finishing, allowing for a comprehensive detailing process.The new polishing pads are also designed to minimize the amount of heat generated during use, reducing the risk of damage to the vehicle's surface. They are also easy to use and can be used with both rotary and dual-action polishers, making them versatile and suitable for a wide range of applications.With the introduction of the 150mm Polishing Pads, the company hopes to improve the detailing process and help professionals and enthusiasts achieve perfect polishing and finishing results. The pads are an important addition to any detailing kit, and their unique design and features make them stand out from other polishing pads in the market.In conclusion, the introduction of the 150mm Polishing Pads is good news for the automotive detailing and restoration industry. The product shows promise in providing an efficient and effective way of achieving the perfect polishing and finishing results. With a range of options available, customers can choose the best grade of polishing pad to suit their specific application, making the new pads a versatile and effective tool for any detailer, restorer, or enthusiast.

Discover the Amazing Benefits of Flexible Stone for Your Home Renovation Project

Flexible Stone: Revolutionizing Construction with Innovation and SustainabilityIn the ever-evolving world of construction, one company is making significant strides towards revolutionizing the industry with its groundbreaking product, Flexible Stone. Combining cutting-edge technology with an unwavering commitment to sustainability, this company is reshaping the way we think about building materials. With a unique blend of durability, versatility, and eco-friendliness, Flexible Stone is paving the way for a greener and more innovative future.Founded in 2010 with a small team of dedicated engineers, the vision behind Flexible Stone was to develop a material that could mimic the look and feel of natural stone while providing the benefits of flexibility, durability, and ease of installation. After years of research and development, the company achieved this feat by creating a proprietary blend of synthetic materials that have transformed the construction industry.What sets Flexible Stone apart from traditional building materials is its adaptability. Unlike natural stone, which is rigid and difficult to work with, Flexible Stone can be bent, molded, and shaped to fit any surface or structure. This unparalleled flexibility opens up a world of possibilities for architects, designers, and builders, allowing them to explore innovative designs and create unique spaces that were once thought to be impossible.Moreover, Flexible Stone's adaptability makes it the ideal material for both interior and exterior applications. From countertops and walls to facades and flooring, this versatile product can be seamlessly integrated into any architectural design. With a wide range of colors and textures to choose from, architects can now unleash their creativity and bring their visions to life without compromising on aesthetics or functionality.In addition to its remarkable versatility, Flexible Stone is also an eco-friendly choice. The company's commitment to sustainability goes beyond the product itself. From the selection of raw materials to the production process, every aspect of Flexible Stone's manufacturing is designed to minimize its environmental impact. By utilizing recycled materials and reducing waste, the company is actively contributing to the preservation of natural resources and the reduction of carbon emissions.Furthermore, Flexible Stone has been rigorously tested and certified for its durability and resistance to various external factors. This robustness ensures that structures built with Flexible Stone will withstand the test of time, even in the harshest weather conditions. Unlike traditional building materials that may crack or deform over time, Flexible Stone retains its shape and appearance, ensuring long-lasting and maintenance-free installations.The benefits of Flexible Stone are not just limited to aesthetics and environmental preservation; they also extend to cost savings. With its lightweight composition, transportation costs are significantly reduced, making it a more cost-effective alternative to natural stone. The ease of installation also minimizes labor costs, saving builders and construction companies valuable time and resources.As the market demand for sustainable and innovative building materials continues to grow, the future looks promising for Flexible Stone. The company's dedication to research and development ensures that new applications and improvements are constantly being explored. With ongoing collaborations with architects and industry experts, Flexible Stone is poised to revolutionize the construction industry and lead the way towards a more sustainable and aesthetically pleasing built environment.In conclusion, with its unprecedented flexibility, durability, and commitment to sustainability, Flexible Stone is transforming the construction landscape. As architects and builders seek innovative solutions that combine functionality, aesthetics, and environmental consciousness, Flexible Stone emerges as a game-changer. By reimagining what is possible in construction, this remarkable product has set a new standard of excellence, opening endless possibilities for the future of architecture and design.

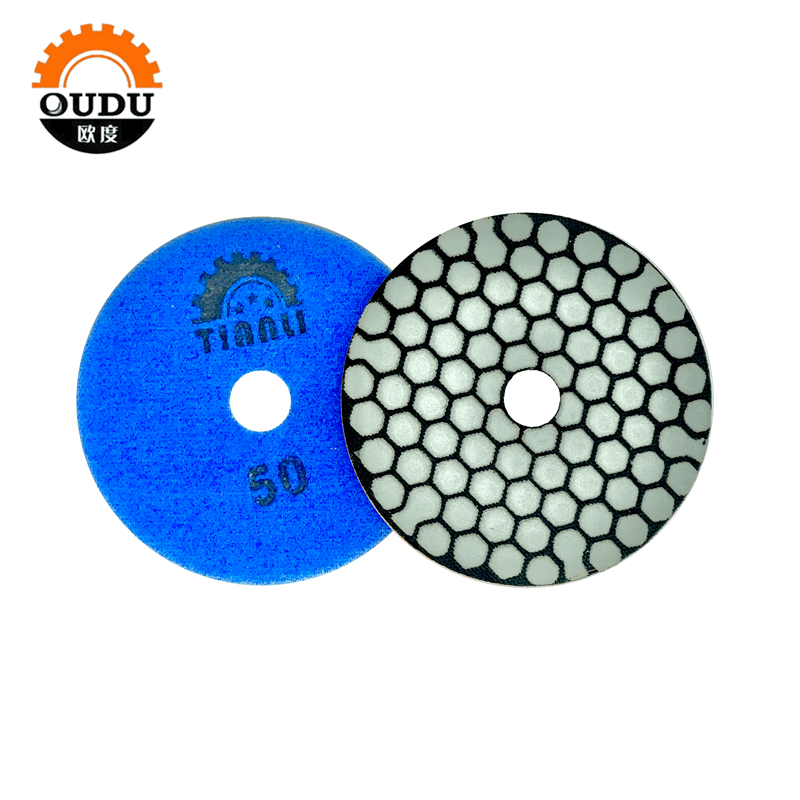

High-Quality Diamond Polishing Pad for Smoothing and Polishing Surfaces

Diamond Polishing Pad, a cutting-edge innovation in the field of diamond polishing technology, is set to revolutionize the way we think about polishing and finishing materials. This state-of-the-art polishing pad is designed to meet the needs of professionals in the stone processing industry, delivering exceptional results and unmatched durability.The Diamond Polishing Pad is a product of extensive research and development, undertaken by a team of experts at our company {}. Our company has been a leading manufacturer and supplier of diamond tools for the stone processing industry for over 20 years. We have built a strong reputation for delivering high-quality products and innovative solutions to our customers, and the Diamond Polishing Pad is the latest addition to our portfolio of cutting-edge products.What sets the Diamond Polishing Pad apart from traditional polishing pads is its use of advanced diamond technology. The pad is embedded with high-quality diamonds, which enables it to achieve a superior level of polishing and finishing. The diamonds are carefully selected and engineered to deliver maximum performance, ensuring that the pad can withstand the rigors of professional use and deliver consistent results.In addition to its diamond-infused design, the Diamond Polishing Pad also features a unique resin formula that enhances its performance and longevity. The resin is specially formulated to provide optimal bonding with the diamonds, ensuring that they remain securely in place even under the most demanding conditions. This allows the pad to maintain its effectiveness and deliver exceptional results over an extended period of use.One of the key advantages of the Diamond Polishing Pad is its versatility. The pad is suitable for use on a wide range of materials, including granite, marble, concrete, and engineered stone. This makes it an ideal solution for professionals who work with different types of stone and require a versatile polishing pad that can deliver consistent results across various applications.The Diamond Polishing Pad is also designed with user convenience in mind. It is available in a range of sizes and grits, allowing professionals to select the pad that best suits their specific requirements. Whether they need to achieve a high-gloss finish or remove scratches and blemishes, the Diamond Polishing Pad offers the flexibility to meet their needs.Furthermore, the durability of the Diamond Polishing Pad ensures that professionals can rely on it for long-term use. Its robust construction and high-quality materials make it resistant to wear and tear, allowing it to maintain its performance and effectiveness over a prolonged period. This not only delivers cost savings for professionals but also minimizes the need for frequent replacements, saving time and effort.As a testament to its quality and performance, the Diamond Polishing Pad has already garnered praise from professionals in the stone processing industry. Its ability to deliver exceptional results and withstand the demands of heavy-duty use has made it a preferred choice for professionals who require reliable and high-performing diamond polishing pads.Looking ahead, our company is committed to continuing our tradition of excellence in delivering innovative solutions to the stone processing industry. The Diamond Polishing Pad is a prime example of our dedication to pushing the boundaries of technology and creating products that meet the evolving needs of our customers. We are confident that the Diamond Polishing Pad will continue to make a significant impact in the industry and set new standards for polishing and finishing materials.

High-Quality 125mm Car Polishing Pads for Ultimate Shine

Car enthusiasts and detailers will be thrilled to hear about the latest addition to the {Company Name} product lineup – the 125mm Car Polishing Pads. These high-quality pads have been specifically designed to provide a professional finish to any car, ensuring a flawless and glossy appearance.The 125mm Car Polishing Pads are made from premium materials, including a carefully selected foam and microfiber blend. This combination allows for maximum effectiveness in removing swirl marks, scratches, and other imperfections from the surface of the vehicle. The pads are also suitable for use with a variety of polishing compounds and can be easily attached to most rotary and dual-action polishers.With a focus on both performance and durability, the {Company Name} 125mm Car Polishing Pads are built to withstand the rigors of regular use. The carefully engineered design ensures that the pads maintain their shape and density, even when subjected to high speeds and pressure. This means that users can rely on the pads to consistently deliver a superior polishing experience without the risk of deterioration or disintegration.In addition to their outstanding performance, the 125mm Car Polishing Pads also offer practical benefits for users. The hook and loop backing ensures quick and easy pad changes, allowing for a seamless transition between different stages of the polishing process. The pads are also machine washable, making them easy to clean and maintain for prolonged use.{Company Name} is renowned for its dedication to providing innovative and high-quality automotive detailing products. The addition of the 125mm Car Polishing Pads to their product range further solidifies their position as a leading supplier in the industry. With a commitment to meeting the needs of professionals and enthusiasts alike, {Company Name} continues to push the boundaries of excellence in car care and maintenance.The comprehensive line of {Company Name} products includes a wide range of polishing compounds, microfiber towels, detailing brushes, and more. These products have gained a loyal following among users who demand nothing less than the best for their vehicles. With the introduction of the 125mm Car Polishing Pads, {Company Name} further demonstrates its unwavering dedication to delivering superior solutions for car detailing and maintenance.The 125mm Car Polishing Pads are set to become an essential addition to the toolkit of every detailer and automotive enthusiast. Their exceptional performance, durability, and user-friendly design make them the perfect choice for achieving professional-grade results when polishing and restoring vehicles. Whether used in professional detailing shops or for personal car care, these pads are sure to impress with their exceptional performance and reliability.{Company Name} remains committed to driving innovation and quality in the automotive detailing industry, and the 125mm Car Polishing Pads are a testament to this ongoing dedication. As car enthusiasts continue to demand the best for their vehicles, {Company Name} stands ready to meet and exceed their expectations with exceptional products like the 125mm Car Polishing Pads.

Discover the Benefits of Cup Wheel Grinding Disc for Efficient Grinding

Cup Wheel Grinding Disc: The Innovative Solution to Your Grinding NeedsGrinding surfaces require the use of abrasive materials for efficient and effective results. Whether you are grinding concrete, marble or granite, achieving a smooth finish and removing the unwanted marks and blemishes on the surface is essential. With the emergence of cup wheel grinding discs, the process of grinding has become more efficient, and the results more impressive.One particular company, known for its manufacturing prowess, has taken the lead in producing industry-grade cup wheel grinding discs. With years of experience in the production of grinding tools and accessories, the company has earned a reputation for excellence and innovation.The cup wheel grinding disc, produced by the company, is a top-of-the-line product that has been engineered to meet the demands of its customers. The product is designed for heavy-duty grinding applications, with its diamond-embedded segments that work to remove stubborn stains, rough surfaces, and other imperfections on the surface with precision and speed.Made with the finest quality materials and advanced manufacturing processes, this cup wheel grinding disc ensures that you get the best results, every time. Here are some of the key features and benefits of using this product:Durable and long-lasting: The diamond segments on the cup wheel grinding disc are designed to last longer and withstand intense pressure, even in high-heat and heavy-duty applications.Efficient and Fast: The unique design and engineering of the product ensure that grinding is done with minimal effort, saving you time and energy.Versatile: The product is suitable for grinding a wide range of surfaces, including concrete, marble, granite, and other materials.Smooth Finish: The diamond-embedded segments on the cup wheel grinding disc work to remove surface marks and leave a smooth finish on the surface, making it ideal for polishing applications.Easy to Use: The cup wheel grinding disc can be easily attached to a variety of grinding machines, making it simple to use for any job.The innovations and technology that have gone into the production of this cup wheel grinding disc have made it a top choice in the market. Whether you are a professional contractor or a DIY enthusiast, you can rest assured that you are getting a high-quality product that delivers on its promises.In SummaryAs demand for grinding surfaces continues to grow, the need for technologically advanced and efficient abrasive tools also rises. That is why the cup wheel grinding disc stands out as an innovative solution to the grinding needs of professionals in the construction and DIY industries.With its exceptional features, durability and engineering, one particular company stands out as a leader in the production of industry-standard cup wheel grinding discs. The diamond-embedded segments of the product make grinding fast, efficient and precise, leaving your surfaces looking immaculate.If you are looking for a reliable and efficient grinding tool, then consider using the cup wheel grinding disc. The quality of the product and its performance is unmatched in the market.

Enhance Your Vehicle's Shine with 7 Inch Buffing and Polishing Pads

The importance of maintaining a clean and polished vehicle cannot be overstated. Not only does it enhance the overall look of the car, but it also ensures that its value is preserved. This is where 7 Inch Buffing and Polishing Pads come in. These pads are the perfect tool for vehicle detailing and provide a quick and easy way to restore that showroom shine to any car.In recent news, a well-known auto detailing company has launched a new range of 7 Inch Buffing and Polishing Pads designed to help customers achieve a high-quality, professional finish. The company, which specializes in car care products, offers a wide range of services and products for both interior and exterior car care. This new range of Buffing and Polishing Pads is just one example of the innovative and effective products that they provide to car enthusiasts around the world.The 7 Inch Buffing and Polishing Pads are made from high-quality materials that ensure long-lasting durability. They come in a variety of different colors, each with a specific purpose. The orange pad, for example, is designed for aggressive cutting and is perfect for removing heavy oxidation and scratches. The green pads, on the other hand, are the perfect choice for removing moderate scratches and swirl marks. The company's unique white pad is perfect for light oxidation removal, while the black pad is designed for finishing and final buffing.In addition to their high-quality materials and variety of uses, the 7 Inch Buffing and Polishing Pads are easy to use and versatile. They can be used with both electric and air-powered polishing machines. The pads are also easy to attach and detach without the need for any special tools. This makes them an ideal choice for anyone looking to achieve a professional finish on their car from the comfort of their own garage.One of the key benefits of the 7 Inch Buffing and Polishing Pads is that they are ideal for a wide range of vehicle types. Whether you have a sports car, SUV, or classic car, these pads can help to restore the shine and make your vehicle look like new again. They are also perfect for boat owners who want to keep their vessels looking their best, as well as owners of motorcycles, ATVs, and other motorized vehicles.The company offering these Buffing and Polishing Pads have a strong reputation in the automotive industry. With years of experience in the field of car care and detailing, they know what customers need and have worked hard to provide it. Their range of products includes everything from car wax and polishes to car wash soaps and brushes.The launch of their new range of 7 Inch Buffing and Polishing Pads is just one example of their commitment to innovation and customer satisfaction. With each new product release, they aim to make the car care process easier and more effective for their customers.In conclusion, the 7 Inch Buffing and Polishing Pads are a must-have for any car enthusiast looking to achieve a high-quality, professional finish on their vehicle. With their superior materials and variety of uses, they are a versatile tool that can help to restore the shine and beauty of any car, boat, or motorcycle. The Launch of this new range of buffing and polishing pads demonstrates the commitment of this reputed company to continue providing the best products to their customers.

The best hardware tools for your next project

Hardware Tools, a leading global provider of high-quality tools and equipment, is making waves in the industry with its latest products and innovations. With a strong focus on performance, durability, and reliability, Hardware Tools is committed to providing customers with the tools they need to get the job done right, every time.Since its inception, Hardware Tools has established itself as a trusted name in the industry, known for its unwavering dedication to quality and customer satisfaction. The company offers a wide range of products, including hand tools, power tools, measuring tools, and more, catering to the needs of professional tradespeople and DIY enthusiasts alike.One of the company's standout products is its line of power tools, which are designed to deliver exceptional performance and efficiency. With features such as powerful motors, ergonomic designs, and innovative technology, Hardware Tools' power tools are built to handle even the toughest jobs with ease. Whether it's drilling, sawing, grinding, or sanding, customers can rely on Hardware Tools to provide them with the tools they need to tackle any task.In addition to power tools, Hardware Tools also offers a comprehensive selection of hand tools, including wrenches, pliers, screwdrivers, and more. These tools are engineered to deliver precision and accuracy, making them an indispensable asset for professionals and hobbyists alike. With a focus on durability and comfort, Hardware Tools' hand tools are designed to withstand the rigors of regular use, ensuring that they can be relied upon for years to come.Furthermore, Hardware Tools is committed to staying at the forefront of technological advancements in the industry. The company continues to invest in research and development, constantly seeking out new innovations and improvements to its product line. By staying ahead of the curve, Hardware Tools ensures that its customers have access to the latest and most advanced tools and equipment available on the market.In addition to its commitment to excellence in product design and development, Hardware Tools also places a strong emphasis on customer service. The company strives to provide customers with a seamless and enjoyable experience, from the moment they start shopping to the time they begin using their new tools. With a dedicated team of knowledgeable and friendly staff, Hardware Tools is always ready to assist customers with any questions or concerns they may have.As a global company, Hardware Tools has a strong presence in markets around the world. With a network of distributors and retailers, the company's products are readily available to customers in a wide range of locations. Whether it's a large-scale construction project or a small home improvement task, customers can trust that Hardware Tools' products will be there to lend a helping hand.Looking ahead, Hardware Tools is poised to continue its upward trajectory in the industry. With a steadfast commitment to quality, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of its customers and maintain its status as a leader in the tools and equipment market.In conclusion, Hardware Tools is a company that is synonymous with quality, reliability, and performance. With a diverse range of products designed to cater to the needs of professionals and hobbyists alike, Hardware Tools is a one-stop destination for all things related to tools and equipment. Coupled with its unwavering dedication to customer service and innovation, Hardware Tools is a brand that customers can trust to deliver the tools they need to succeed.

Revolutionary 3-Step Process for Achieving a Flawless Dry Polished Finish

Title: Revolutionary 3-Step Dry Polishing Pads Transforming the Polishing IndustryIntroduction:In the ever-evolving world of polishing, advanced technologies continue to revolutionize the industry. One such groundbreaking product is the newly introduced 3-Step Dry Polishing Pads, developed by a renowned company at the forefront of innovation in the field. These cutting-edge pads have been designed to enhance efficiency and ease in the polishing process, offering a game-changing solution for professionals and DIY enthusiasts alike. In this article, we delve into the features and benefits of this remarkable product, highlighting its potential to transform the way we approach polishing.1. Unveiling the 3-Step Dry Polishing Pads:The 3-Step Dry Polishing Pads are crafted from premium quality materials and feature a unique design that sets them apart from traditional polishing pads. They are specifically engineered for use on a variety of surfaces, including stone, concrete, marble, and granite. These pads work exceptionally well on both wet and dry surfaces, making them a versatile tool for any polishing project.The company behind this innovation, known for their commitment to excellence, has extensively researched and tested these pads to ensure their optimum performance. By utilizing the latest technologies, they have successfully developed a product that exceeds expectations, promising exceptional results in a fraction of the time.2. Three-Step Process for Unparalleled Efficiency:The 3-Step Dry Polishing Pads utilize a simple yet highly effective three-step process that streamlines the polishing procedure, saving valuable time and effort. Let's explore each step:Step 1: Coarse Polishing: The initial stage of the process involves the use of a coarse pad that efficiently removes imperfections, such as scratches, blemishes, and marks from the surface. This coarse pad creates a smooth and even base, preparing the surface for further polishing.Step 2: Medium Polishing: Once the imperfections have been successfully removed, the medium pad is utilized to further refine and smoothen the surface. This step enhances the clarity and shine of the material, ensuring a gleaming final result.Step 3: Fine Polishing: The final step involves the fine pad, which delivers an impeccable finish by eliminating any remaining imperfections and creating a mirror-like surface. This stage of the process enhances the vibrancy and depth of the material, leaving a stunning and long-lasting shine.3. Key Benefits of the 3-Step Dry Polishing Pads:The introduction of the 3-Step Dry Polishing Pads brings with it a plethora of advantages that make them an indispensable tool for professionals and DIY enthusiasts alike. Let's explore some of these benefits:Time and Cost Efficiency: These pads significantly reduce the time and effort needed to achieve a polished surface. With their three-step process, the pads eliminate the need for multiple rounds of polishing, saving both time and money.Versatility: The 3-Step Dry Polishing Pads are suitable for various surfaces, making them a versatile option for numerous projects. Whether it's stone, concrete, marble, or granite, these pads deliver exceptional results on all fronts.Ease of Use: The user-friendly design of these pads ensures that professionals and beginners alike can achieve outstanding results effortlessly. The step-by-step process allows for seamless polishing, eliminating the guesswork and minimizing errors.Durability: Crafted from high-quality materials, these pads are built to withstand heavy-duty use. Their durability ensures a long lifespan, translating into cost savings for users in the long run.Environmental Friendly: The dry nature of these pads reduces the need for excessive water usage during the polishing process. This eco-friendly feature not only conserves water but also keeps the work area clean and tidy.Conclusion:The introduction of the 3-Step Dry Polishing Pads marks a turning point in the world of polishing. With their revolutionary design, ease of use, and exceptional results, these pads are poised to transform the industry. The combination of time and cost efficiency, versatility, and environmental friendliness makes them an essential tool for anyone seeking a game-changing solution for their polishing needs. Embrace this groundbreaking innovation and witness unmatched performance in your polishing projects.

Ceramic Grinding Discs: Latest News and Insights to Optimize Your Grinding Efficiency

Title: Revolutionary Ceramic Grinding Disc Revolutionizes Material FinishingIntroduction:In today's rapidly evolving industrial world, the demand for high-quality surface finishes has become paramount. Companies across various sectors are continuously seeking innovative solutions to achieve efficient and precise material finishing to meet the growing consumer demands. This has led to the development of a breakthrough product in the form of the Ceramic Grinding Disc. This news article will delve into the benefits and applications of this remarkable tool, exploring the company {company name} behind its creation and outlining its potential to revolutionize material finishing.I. Readying the Stage for Revolutionary Grinding Techniques (150 words)With traditional grinding tools competing to deliver the highest level of precision, the Ceramic Grinding Disc emerges as a game-changer in the industry. Developed by {company name}, a renowned manufacturer of cutting-edge abrasive products, this disc offers unmatched performance, durability, and quality.II. Unveiling the Ceramic Grinding Disc's Cutting-Edge Technology (150 words)The Ceramic Grinding Disc stands out due to its utilization of advanced materials and manufacturing techniques. Made from high-quality ceramic particles, the disc exhibits exceptional hardness, enabling it to maintain its sharpness and provide consistent performance throughout its use. Its superior heat and wear resistance make it suitable for a wide range of applications, including metal, stainless steel, and even exotic alloy material finishes.III. The Unparalleled Advantages of the Ceramic Grinding Disc (200 words)Thanks to its unique attributes, the Ceramic Grinding Disc offers several advantages over traditional abrasive tools. Firstly, its durability ensures a longer lifespan, reducing the frequency of tool replacements and lowering overall production costs. Additionally, its sharp cutting capabilities significantly enhance material removal rates, leading to improved efficiency and productivity. Moreover, the disc's exceptional heat resistance prevents overheating during demanding applications, resulting in reduced workpiece damage and improved machine operator safety. IV. Applications and Industries Benefitting from the Ceramic Grinding Disc (150 words)The versatility of the Ceramic Grinding Disc allows it to find applications in a multitude of industries. In the metalworking sector, manufacturers can achieve flawless surface finishes on steel, aluminum, and cast iron components. In the automotive industry, this cutting-edge tool can be employed for precision grinding of engine parts, brakes, and transmissions. Moreover, the disc finds use in the aerospace sector for deburring, grinding, and surface preparation of intricate components. The construction and woodworking sectors also benefit from the disc's versatility in shaping and smoothing a wide array of materials.V. The Visionary Masterminds behind the Ceramic Grinding Disc (150 words){Company name}, the pioneering force behind the Ceramic Grinding Disc, has a long-standing reputation for developing innovative abrasive solutions. Committed to pushing the boundaries of what's possible, the company invests heavily in research and development. Their expertise, combined with a deep understanding of the industry's challenges, has culminated in the creation of this extraordinary tool. With a track record of delivering premium products and an unwavering commitment to customer satisfaction, {company name} aims to transform the way manufacturers approach material finishing.Conclusion:As the demand for impeccable material finishes continues to grow, the Ceramic Grinding Disc emerges as a revolutionary solution. Offering unrivaled performance, durability, and versatility across multiple industries, this cutting-edge tool represents a paradigm shift in material finishing. In collaboration with {company name}, manufacturers can now achieve exceptional results while increasing productivity, reducing costs, and improving safety.