Efficient Diamond Grinding Tools for Smooth Concrete Finishing

By:Admin

[City], [Date] - [Company], a leading manufacturer in the construction equipment industry, is revolutionizing the way concrete is ground down with its innovative Diamond Grinding Tools. As an essential component in the construction sector, these tools are poised to change the landscape of concrete grinding, bringing forth unprecedented speed, efficiency, and precision.

Concrete grinding has long been a necessary but labor-intensive process in the construction industry. Traditionally, grinding is achieved by using abrasive stones or metal discs, which can be time-consuming, physically demanding, and prone to errors. However, with the introduction of [Company's Diamond Grinding Tools], contractors can now enjoy a streamlined and superior grinding experience.

[Company's Diamond Grinding Tools] are crafted using state-of-the-art technology and high-quality materials. The tools are embedded with industrial-grade diamonds, which significantly enhances their grinding performance, efficiency, and durability. With their exceptional wear resistance, these tools require fewer replacements, leading to reduced downtime and increased productivity on construction sites.

Furthermore, one of the distinguishing features of [Company's Diamond Grinding Tools] is their ability to maintain a consistent depth of cut. This ensures the surface being worked on remains level and uniform throughout the grinding process, eliminating the need for costly and time-consuming rework. The precision achieved with these tools allows contractors to deliver high-quality results consistently, gaining them a competitive edge in the industry.

Another significant advantage of [Company's Diamond Grinding Tools] is their efficiency in removing a wide range of coatings and surface imperfections. Whether it be glue, epoxy, paint, or uneven surfaces, these tools possess the strength and precision to eliminate them effortlessly, reducing the need for additional remediation steps. This versatility not only saves time but also reduces the overall project costs, making it an attractive option for contractors and clients alike.

In addition to their performance, [Company's Diamond Grinding Tools] are designed to prioritize operator comfort and safety. Fitted with ergonomic handles and vibration-dampening technology, these tools minimize operator fatigue and reduce the risk of work-related injuries. The design also incorporates effective dust collection systems, ensuring a cleaner working environment and protecting the health of the workers.

"We are proud to introduce our Diamond Grinding Tools to the market," said [Company spokesperson name], [Company's] spokesperson. "We believe that these tools will revolutionize the way concrete grinding is performed. By combining cutting-edge technology, durability, and operator comfort, we are confident that contractors will experience unprecedented levels of efficiency and productivity."

The response from the construction industry has been overwhelmingly positive. Contractors who have tested [Company's Diamond Grinding Tools] have reported significant reductions in project completion times, increased customer satisfaction, and improved profitability.

With [Company] leading the way in concrete grinding innovation, the construction industry is set to undergo a transformative change. Contractors will now have access to tools that combine precision, efficiency, and operator comfort, enabling them to tackle even the most challenging projects with ease.

[Company], with its commitment to excellence and innovation, continues to push the boundaries of the construction equipment industry. The introduction of [Company's Diamond Grinding Tools] marks a significant milestone in the pursuit of improving efficiency and quality within the construction sector. As the industry eagerly embraces this groundbreaking technology, it is clear that [Company] is at the forefront of shaping the future of construction practices.

About [Company]:

[Company] is a renowned manufacturer and supplier of cutting-edge construction equipment. With a keen understanding of industry requirements, [Company] strives to deliver innovative solutions that cater to the unique needs of contractors across the globe. The company's commitment to excellence, quality craftsmanship, and customer satisfaction has propelled it into becoming a trusted leader in the construction equipment market.

Company News & Blog

Nylon Drill Brush: An Effective Tool for Wheel Cleaning

Recently, a new product has been making waves in the cleaning industry - the Nylon Wheel Brush for Drill. This innovative attachment is designed to make cleaning difficult and hard-to-reach areas easier and faster. With its unique design, users no longer have to struggle with cleaning wheels, tight corners, and other intricate parts of their homes or cars.This Nylon Wheel Brush is made with a durable nylon bristle that effectively removes dirt, dust, and grime accumulated in hard-to-reach areas. The bristles are carefully crafted and arranged to ensure a smooth, even clean with minimal damage to surfaces.One of the main benefits of the Nylon Wheel Brush for Drill is its versatility. It can be used on a wide range of materials like metal, plastic, and wood, making it ideal for use in a variety of cleaning situations. Whether you need to clean car wheels, furniture, or tiles, this brush will quickly and efficiently take care of the job.The Nylon Wheel Brush for Drill is also easy to use. As the name suggests, it requires a drill to function. Simply attach the brush to the drill and let the high-speed rotation do the work for you. This eliminates the need to use excessive amounts of elbow grease to get the job done.Furthermore, the Nylon Wheel Brush for Drill is highly durable, meaning it is built to withstand heavy usage and won't easily wear out or break. The bristles are made from high-quality nylon fibers that are resistant to heat, water, and most chemicals, ensuring that it remains in excellent condition even after multiple uses.This handy tool is designed and manufactured by {manufacturer's name}, a leader in the cleaning industry. The company has been producing high-quality cleaning products for many years, making it a trusted industry name. Their products are renowned for their quality, effectiveness, and durability, and the Nylon Wheel Brush for Drill is no exception.{Manufacturer's name} takes pride in employing skilled technicians who use the latest technology and equipment to produce high-quality products. They guarantee that their products are manufactured to meet the highest industry standards and subjected to rigorous testing to ensure they meet customer expectations.When it comes to storage, the Nylon Wheel Brush for Drill is easy to store. It is small in size and can fit easily into a tool kit or storage pouch. This makes it a convenient tool to have when traveling or when you need to clean on the go.In conclusion, the Nylon Wheel Brush for Drill is a must-have tool for anyone looking to clean tricky and hard-to-reach areas effectively and efficiently. With its high-quality construction and highly versatile design, users can rest assured that they are investing in a quality product that will last them for years to come. Thanks to its ease of use and durability, cleaning is no longer a chore but a breeze with the Nylon Wheel Brush for Drill.

Understanding the Strength and Characteristics of Metallic Bonds in Steel

Title: Groundbreaking Innovation in Metal Bonding Techniques Unveiled by Leading Manufacturer Introduction: In a revolutionary leap forward, a prominent manufacturer in the metal industry has developed an advanced metal bonding technique that promises to redefine the world of steel manufacturing. By leveraging cutting-edge technology and expertise, this innovative process aims to enhance the efficiency, strength, and versatility of metallic bonding, opening up new possibilities across various industries. Read on to discover how Steel Metallic Bonds (SMB), a pioneering metal bond solution, is set to transform the manufacturing landscape.1. The Evolution of Metallic Bonding Techniques:Since the advent of metallurgy, researchers and manufacturers have constantly pursued improved ways to bond metal materials. Conventional welding and adhesive bonding techniques have served as the backbone of metal fabrication for centuries. However, with the introduction of SMB technology, a seismic shift in the way metals are joined is on the horizon.2. The Science Behind Steel Metallic Bonds (SMB):Steel Metallic Bonds (SMB) is a state-of-the-art metal bonding technology that relies on a unique chemical process and advanced robotics. The process involves the formation of interatomic bonding between metal particles, resulting in an incredibly strong bond that surpasses traditional joining methods. This breakthrough technique allows for precise control of bond strength and ensures uniform distribution of stress, circumventing weak points and vulnerabilities.3. Key Advantages of Steel Metallic Bonds:i. Unparalleled Strength: SMB generates bonds with exceptional strength and durability, making it ideal for high-stress applications such as aerospace, automotive, and construction. The uniform distribution of stress allows for enhanced load-bearing capabilities, contributing to the overall safety and longevity of the final product.ii. Enhanced Efficiency: Unlike conventional methods such as welding, SMB eliminates the need for melting and fusion, significantly reducing energy consumption and production time. Faster production cycles translate into improved cost-efficiency, making SMB an attractive choice for manufacturers looking to streamline their operations.iii. Versatility: Steel Metallic Bonds offer unmatched versatility, enabling the bonding of different metals and alloys that were previously considered incompatible. This breakthrough technology opens up new design possibilities and materials combinations, fostering innovation across industries.iv. Corrosion Resistance: One of the notable advantages of SMB is its inherent resistance to corrosion. By minimizing the presence of exposed areas in the bonded joints, this innovative technique provides an added layer of protection against environmental factors, ultimately extending the lifecycle of metal structures.4. Applications Across Industries:i. Aerospace: Steel Metallic Bonds offer aerospace manufacturers the opportunity to develop lighter, stronger, and more fuel-efficient aircraft. By replacing traditional rivets and welding techniques, SMB enables the creation of seamless structures with improved aerodynamic properties.ii. Automotive: In the automotive sector, SMB unlocks new possibilities for lightweight designs, contributing to better fuel efficiency and reduced emissions. Additionally, the enhanced bonding strength ensures the structural integrity of various components, improving overall safety.iii. Construction: Steel Metallic Bonds revolutionize the construction industry by offering builders the ability to create stronger and more resilient structures. From skyscrapers to bridges, this breakthrough technology ensures strength, durability, and resistance to external forces, resulting in safer buildings with extended lifespans.iv. Electronics: The precise control over bonding strength and the ability to join dissimilar metals make SMP an ideal solution for the electronics industry. This technology holds the potential to revolutionize electronic packaging, improving heat dissipation, reducing size, and enhancing product performance.Conclusion: The advent of Steel Metallic Bonds (SMB), a cutting-edge metal bonding solution, marks a groundbreaking milestone in the manufacturing industry. By combining advanced chemistry, robotics, and engineering, the SMB process offers unparalleled strength, enhanced efficiency, and unmatched versatility. With applications ranging from aerospace to construction and electronics, SMB has the potential to reshape multiple sectors, enabling innovation and ensuring the development of safer, more durable, and sustainable products. As industries evolve, Steel Metallic Bonds will undoubtedly play a prominent role in shaping the future of steel manufacturing and beyond.

Discover the Benefits of Wire Brush Grinding Wheels

Title: Industry Leader Introduces Innovative Wire Brush Grinding Wheel to Enhance Metal Surface PreparationIntroduction:[Company Name], a renowned industry leader in manufacturing high-quality metalworking tools and equipment, is proud to announce the launch of their latest product innovation — the Wire Brush Grinding Wheel. Designed to revolutionize metal surface preparation, this cutting-edge tool offers exceptional performance, durability, and efficiency, catering to professionals across various industries.Blending state-of-the-art technology with years of expertise, [Company Name] has successfully developed a Wire Brush Grinding Wheel that surpasses existing market offerings in terms of quality and functionality. This innovative tool is set to enable professionals to achieve precise and effective metal surface preparation, ensuring excellent results in a wide range of applications such as welding, painting, and coating.Product Features:The Wire Brush Grinding Wheel features a unique combination of high-grade wire bristles and an advanced grinding wheel. The wire bristles are skillfully designed and evenly spaced, ensuring efficient removal of rust, scale, and other contaminants from metal surfaces. The grinding wheel, made of premium abrasives, ensures smooth and precise grinding, resulting in a flawless surface ready for subsequent processes.Moreover, the Wire Brush Grinding Wheel incorporates an ergonomic design that allows for comfortable and safe handling during extended periods of use. The tool's lightweight construction reduces operator fatigue and increases overall productivity.Industry-leading professionals who have tested the Wire Brush Grinding Wheel express their satisfaction with its superior performance and durability. Unlike traditional abrasive wheels that wear out quickly, this innovative tool maintains its grinding power and wire bristle efficiency over extended periods, reducing downtime and enabling longer operational life.Applications:The Wire Brush Grinding Wheel caters to diverse industries, including manufacturing, construction, automotive, and metal fabrication. Professionals engaged in surface preparation, metal cleaning, and restoration processes can benefit greatly from this tool's exceptional capabilities.In metal manufacturing, the Wire Brush Grinding Wheel proves invaluable in surface conditioning, deburring, and weld seam cleaning. It easily removes rust, paint, and scale from surfaces, preparing them for subsequent processes like painting, welding, or coating.For automotive enthusiasts and mechanics, the Wire Brush Grinding Wheel is a game-changer. From removing stubborn surface contaminants to restoring old parts, this tool ensures a smooth and clean surface ready for paint or further refurbishment.Furthermore, contractors involved in construction projects can rely on the Wire Brush Grinding Wheel for efficient surface preparation of metal structures, ensuring optimal adherence for protective coatings.Conclusion:[Company Name] continues to establish itself as an industry leader by introducing groundbreaking products to enhance metalworking processes. The Wire Brush Grinding Wheel is a testament to the company's commitment to providing professionals with innovative and reliable tools that deliver outstanding results.Featuring an exceptional combination of wire bristles and cutting-edge grinding wheel technology, this new product offers unmatched performance, durability, and efficiency. [Company Name] has once again raised the bar in metal surface preparation, catering to a wide range of industries such as manufacturing, construction, automotive, and metal fabrication.Professionals can now embrace the Wire Brush Grinding Wheel as their go-to tool for achieving flawless metal surfaces, ensuring a seamless transition to subsequent processes such as welding, painting, and coating. With this latest innovation, [Company Name] reaffirms its status as a pioneer in the metalworking industry, consistently delivering premium solutions that meet the evolving needs of professionals worldwide.

Revolutionary New Invention Offers Efficient and Time-Saving Solution for Handcrafted Products

[News Headline]Revolutionary Handheld Machine Introduces Innovative Solutions for Industries[Date][City], [State] - In a groundbreaking move, a leading technology company is set to redefine industries with their latest innovation, a revolutionary handheld machine. This groundbreaking device promises to streamline operations, enhance efficiency, and elevate productivity across different sectors. By removing tedious manual tasks and introducing cutting-edge technology, this versatile handheld machine is positioned to become a game-changer in the industry.With a commitment to pushing the boundaries of innovation, the tech company has introduced this handheld machine that is capable of transforming a wide range of industries. Equipped with advanced features and functionalities, this handheld device aims to simplify complex tasks and offer solutions to some of the most pressing challenges faced by today's businesses.The handheld machine offers a wide array of applications across various sectors, such as manufacturing, logistics, agriculture, healthcare, and more. Companies can leverage this device to automate processes, improve accuracy, and reduce human errors. This "all-in-one" solution enables organizations to optimize workflows, ultimately leading to cost savings and increased productivity.Manufacturing industries, for instance, can benefit greatly from this handheld machine. The device can assist in quality control inspections, data collection, and real-time monitoring. Its built-in sensors and analytics capabilities ensure that faulty products are identified promptly, while performance data helps in making informed decisions to improve overall efficiency.In the logistics sector, this handheld machine streamlines inventory management, supply chain processes, and package tracking. With its portable design and powerful computing capabilities, the device empowers logistics personnel to perform tasks efficiently and on the move. This innovation provides real-time data visibility, enabling companies to achieve optimal inventory levels and reduce shipment delays.Farmers and agricultural workers can also reap the benefits of this handheld machine. From soil testing to crop monitoring, this device provides essential data and analysis to improve agricultural practices. By equipping farmers with actionable insights, this handheld machine contributes to sustainable farming, resulting in increased yields and reduced resource wastage.The healthcare industry is not exempt from this handheld machine's potential transformative impact. Medical professionals can leverage its capabilities in patient monitoring, data collection, and treatment planning. Featuring secure data transfer and storage, this device ensures patient confidentiality and enables swift decision-making, improving overall patient care."Our handheld machine has been carefully designed to meet the diverse needs of different industries. We believe that by empowering businesses with this innovative device, we can drive efficiency, productivity, and success across the board," said a spokesperson from the tech company.The handheld machine's introduction has been met with anticipation and excitement from industry experts. Many recognize its potential to revolutionize operations and bring about substantial improvements in the way businesses function.While the company behind this invention remains committed to continual improvement and innovation, industry insiders are already buzzing with speculation about future developments that may take this handheld machine to the next level. With an ever-growing demand for streamlined operations, enhanced efficiency, and increased productivity, the possibilities for this handheld machine seem boundless.###[Company Introduction][Company Name] is a global technology company dedicated to pushing the boundaries of innovation. With a focus on developing groundbreaking solutions for a wide range of industries, [Company Name] aims to simplify complex processes and drive efficiency. Through constant research, development, and collaboration, the company remains at the forefront of technological advancements.Headquartered in [Location], [Company Name] boasts a team of highly skilled professionals who are passionate about creating industry-leading products. Their dedication and expertise contribute to the design and development of cutting-edge solutions that address the unique challenges faced by different sectors. With a commitment to quality and customer satisfaction, [Company Name] has established itself as a trusted provider of innovative technologies.By consistently delivering groundbreaking solutions, [Company Name] remains a preferred choice for businesses seeking to optimize operations, enhance productivity, and embrace the potential of emerging technologies. The introduction of their handheld machine further solidifies their position as a leading provider of innovative solutions.For more information about [Company Name] and their groundbreaking handheld machine, please visit [Website].

Discover the Latest Advancements in Grinding Wheels for Enhanced Precision and Efficiency

Grinding wheels are an essential tool for any metalworking or manufacturing process, with thousands of different varieties to choose from depending on the specific job requirements. They are used to shape, grind, and polish various materials, from steel and aluminum to ceramics and glass. A grinding wheel is typically made up of abrasive grains that are bonded together with a matrix, making it a durable and efficient cutting tool that can easily be replaced when it becomes worn.One of the leading manufacturers of grinding wheels is based in China and specializes in producing high-quality abrasive tools for industrial and commercial applications. They have a wide range of grinding wheels available, including diamond wheels, CBN wheels, resin-bonded wheels, and vitrified wheels, all of which are designed to deliver superior performance and reliability.One of the key benefits of using grinding wheels from this company is their durability. Their products are made from high-quality materials that are designed to withstand the wear and tear of daily use, so they last longer and require less frequent replacement. This also means that they can be used in high-speed applications without worrying about them breaking or wearing down too quickly.Another advantage of using these grinding wheels is their versatility. They offer a wide range of options specifically tailored to different applications, from heavy-duty grinding and cutting to precision polishing and finishing. This makes it easy for businesses to find the perfect grinding wheel for their specific needs, no matter how specialized or unique the job might be.Additionally, this company prides itself on its commitment to quality. They use only the highest quality materials and employ strict quality control measures throughout the manufacturing process to ensure that every product they produce meets their exacting standards. This not only helps ensure consistent performance and reliability but also gives customers peace of mind knowing that they are getting a product they can trust.Finally, the company is dedicated to providing excellent customer service and support. They offer personalized assistance to help customers choose the right grinding wheel for their needs, and they also provide ongoing technical support and maintenance tips to help users get the most out of their products. The company also offers fast and reliable shipping, so customers can get their grinding wheels quickly and efficiently.Overall, the manufacturing of grinding wheels has become an important aspect of industrial and commercial processes. These essential tools help shape and transform materials into products we use every day. With their reliability, durability, and consistent quality, grinding wheels from this company are sure to be a valuable addition to any manufacturing or metalworking operation.

Master the Art of Floor Polishing: Unveiling the Ultimate Polishing Pad

release.Floor Polishing Pad: The Ultimate Solution for Polishing and Cleaning FloorsFloor polishing is a crucial process that every homeowner or business owner should consider to maintain the beauty and durability of their floors. Proper polishing enables you to remove scratches, scuffs, stains, and other stubborn dirt from your floors, leaving them sparkling clean and smooth. However, you need to have the right tool for the job, and that's where the Floor Polishing Pad comes in.The Floor Polishing Pad is a revolutionary product that has taken the floor polishing market by storm. It's a high-quality, durable pad that's designed to provide exceptional polishing and cleaning results for various floor surfaces such as hardwood, marble, concrete, terrazzo, and more. The pad is made from premium materials that are designed to withstand constant use and high pressure, making it the perfect tool for both commercial and residential use.One of the outstanding features of the Floor Polishing Pad is its versatility. It's designed to fit a wide range of floor polishing machines, making it an ideal accessory for professionals and DIY enthusiasts alike. The pad is available in various sizes and shapes to fit different floor polishing machines, allowing you to achieve the desired results with ease.Another advantage of the Floor Polishing Pad is its excellent performance. The pad is designed to deliver outstanding results, leaving your floors looking clean, shiny, and well-polished. The pad is made using cutting-edge technology, ensuring that every strand of fiber is perfectly aligned to ensure optimal performance. The pad is also designed with a unique diamond pattern that ensures uniform distribution of pressure and heat, preventing any damage to the floor surface.The Floor Polishing Pad is also designed to be environmentally friendly. It's made using non-toxic, biodegradable materials, making it safe for use in both residential and commercial settings. The pad doesn't contain any harmful chemicals that may harm the environment or pose a risk to human health. Moreover, it's easy to clean and maintain, ensuring that it remains in perfect condition for long.In conclusion, the Floor Polishing Pad is the ultimate solution for anyone looking to achieve exceptional results when polishing and cleaning their floors. Whether you're a professional or a DIY enthusiast, this pad provides the perfect tool for any floor polishing application. Its versatility, outstanding performance, and environmental friendliness make it a top choice for anyone looking to maintain their floors' beauty and durability. So, why wait? Get your Floor Polishing Pad today and experience the difference.

Efficient Diamond Grinding Tools for Smooth Concrete Finishing

Concrete Diamond Grinding Tools Revolutionize the Construction Industry[City], [Date] - [Company], a leading manufacturer in the construction equipment industry, is revolutionizing the way concrete is ground down with its innovative Diamond Grinding Tools. As an essential component in the construction sector, these tools are poised to change the landscape of concrete grinding, bringing forth unprecedented speed, efficiency, and precision.Concrete grinding has long been a necessary but labor-intensive process in the construction industry. Traditionally, grinding is achieved by using abrasive stones or metal discs, which can be time-consuming, physically demanding, and prone to errors. However, with the introduction of [Company's Diamond Grinding Tools], contractors can now enjoy a streamlined and superior grinding experience.[Company's Diamond Grinding Tools] are crafted using state-of-the-art technology and high-quality materials. The tools are embedded with industrial-grade diamonds, which significantly enhances their grinding performance, efficiency, and durability. With their exceptional wear resistance, these tools require fewer replacements, leading to reduced downtime and increased productivity on construction sites.Furthermore, one of the distinguishing features of [Company's Diamond Grinding Tools] is their ability to maintain a consistent depth of cut. This ensures the surface being worked on remains level and uniform throughout the grinding process, eliminating the need for costly and time-consuming rework. The precision achieved with these tools allows contractors to deliver high-quality results consistently, gaining them a competitive edge in the industry.Another significant advantage of [Company's Diamond Grinding Tools] is their efficiency in removing a wide range of coatings and surface imperfections. Whether it be glue, epoxy, paint, or uneven surfaces, these tools possess the strength and precision to eliminate them effortlessly, reducing the need for additional remediation steps. This versatility not only saves time but also reduces the overall project costs, making it an attractive option for contractors and clients alike.In addition to their performance, [Company's Diamond Grinding Tools] are designed to prioritize operator comfort and safety. Fitted with ergonomic handles and vibration-dampening technology, these tools minimize operator fatigue and reduce the risk of work-related injuries. The design also incorporates effective dust collection systems, ensuring a cleaner working environment and protecting the health of the workers."We are proud to introduce our Diamond Grinding Tools to the market," said [Company spokesperson name], [Company's] spokesperson. "We believe that these tools will revolutionize the way concrete grinding is performed. By combining cutting-edge technology, durability, and operator comfort, we are confident that contractors will experience unprecedented levels of efficiency and productivity."The response from the construction industry has been overwhelmingly positive. Contractors who have tested [Company's Diamond Grinding Tools] have reported significant reductions in project completion times, increased customer satisfaction, and improved profitability.With [Company] leading the way in concrete grinding innovation, the construction industry is set to undergo a transformative change. Contractors will now have access to tools that combine precision, efficiency, and operator comfort, enabling them to tackle even the most challenging projects with ease.[Company], with its commitment to excellence and innovation, continues to push the boundaries of the construction equipment industry. The introduction of [Company's Diamond Grinding Tools] marks a significant milestone in the pursuit of improving efficiency and quality within the construction sector. As the industry eagerly embraces this groundbreaking technology, it is clear that [Company] is at the forefront of shaping the future of construction practices.About [Company]:[Company] is a renowned manufacturer and supplier of cutting-edge construction equipment. With a keen understanding of industry requirements, [Company] strives to deliver innovative solutions that cater to the unique needs of contractors across the globe. The company's commitment to excellence, quality craftsmanship, and customer satisfaction has propelled it into becoming a trusted leader in the construction equipment market.

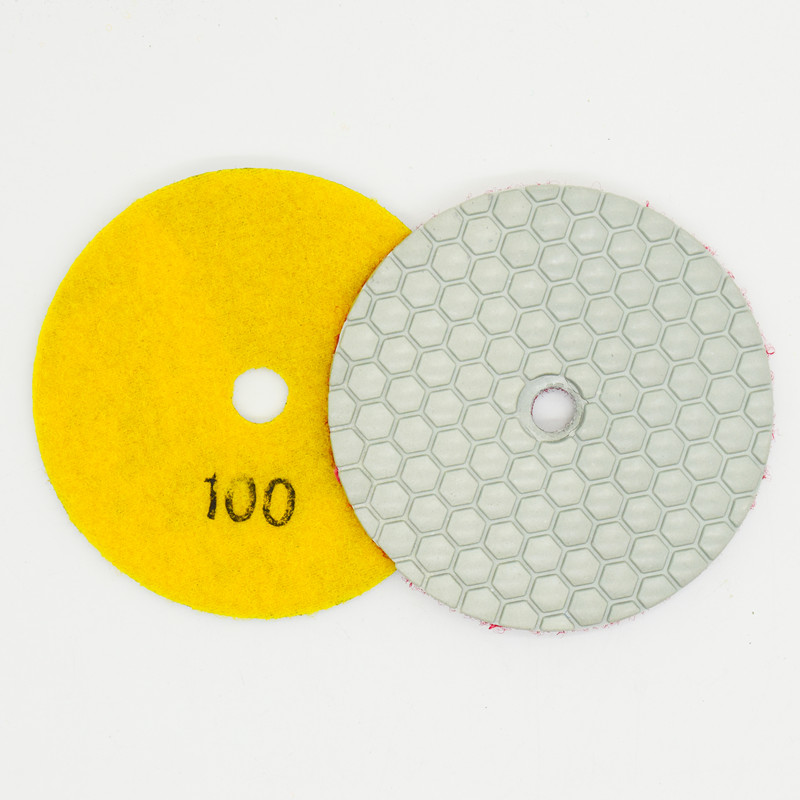

High-Quality Concrete Buffing Pads for Superior Results

Title: Revolutionary Concrete Buffing Pads Redefining Surface PolishingIntroduction:In the world of concrete surface polishing, {Company Name} has established itself as a renowned leader with its innovative range of high-quality products and solutions. Their concrete buffing pads, designed to deliver exceptional performance, are now revolutionizing the industry, leaving their competitors in the dust. These state-of-the-art pads not only effectively remove brand or name marks but also provide unmatched durability, efficiency, and ease of use. Offering a comprehensive solution for professionals and DIY enthusiasts alike, {Company Name}'s concrete buffing pads have become the go-to choice for achieving the perfect polished finish.I. The Importance of Concrete Surface PolishingConcrete surface polishing has gained significant traction over the years. Polished concrete offers numerous advantages, including improved appearance, increased durability, low maintenance, and enhanced environmental friendliness. Whether for residential, commercial, or industrial purposes, concrete polishing has become the preferred option for achieving sleek and long-lasting flooring.II. The Revolutionary Concrete Buffing Pads{Company Name}'s concrete buffing pads have emerged as a game-changer in the surface polishing industry. These pads are meticulously engineered using cutting-edge technology, ensuring optimal performance and unbeatable results. They are formulated with specially designed abrasive particles that efficiently remove blemishes while delivering a high-gloss shine without sacrificing durability.III. Unmatched Durability and LongevityOne of the key factors that sets {Company Name}'s concrete buffing pads apart from the competition is their exceptional durability. These pads are built to withstand the rigors of heavy-duty polishing, ensuring maximum productivity and longevity. By incorporating advanced polymers and reinforced materials, the pads retain their shape, preventing premature wear and tear, and reducing replacement costs.IV. Increased Efficiency and Time-Saving Benefits{Company Name}'s concrete buffing pads offer unparalleled efficiency, helping professionals and DIY enthusiasts complete their projects swiftly. The pads' unique design maximizes contact with the concrete surface, distributing pressure evenly and minimizing polishing time. With these pads, users can achieve a flawless finish in less time, allowing for increased productivity and reduced labor costs.V. User-Friendly Design and Ease of UseRecognizing the importance of user convenience, {Company Name} has prioritized the user-friendly design of their concrete buffing pads. These pads are effortless to attach and remove, enabling smooth transitions between different grit levels without any hassle. Additionally, their flexible nature allows for easy maneuvering and polishing over uneven surfaces, enhancing overall usability.VI. Versatility and Adaptability{Company Name}'s concrete buffing pads accommodate a wide range of applications, making them an invaluable asset for professionals across diverse industries. From small-scale residential projects to large industrial complexes, these pads excel in various settings, delivering consistent performance. Furthermore, they are compatible with most standard polishing machines, ensuring accessibility and ease of adoption.VII. Environmental SustainabilityAlongside their exceptional performance, {Company Name}'s concrete buffing pads prioritize environmental sustainability. These pads are manufactured using eco-friendly materials, minimizing the ecological impact of the cleaning and polishing process. By choosing these pads, users can contribute to a greener future without compromising on quality or efficiency.Conclusion:{Company Name} has undoubtedly raised the bar for concrete surface polishing with their groundbreaking concrete buffing pads. Providing superior performance, unmatched durability, increased efficiency, and ease of use, these pads have become the go-to choice for professionals and DIY enthusiasts alike. With the ability to remove brand or name marks effectively, {Company Name}'s concrete buffing pads have solidified their position as leaders in the industry, revolutionizing surface polishing one project at a time.

Nylon Brush for Angle Grinder - An In-Depth Look at Its Uses and Benefits

Industrial tools have been an integral part of the manufacturing and construction industry, and industrial brushes make up a significant part of this category. Many industries rely on brushes as they play a crucial role in finishing surfaces, cleaning machinery, and much more. One notable type of industrial brush is the nylon brush for an angle grinder. It is a highly specialized tool that is ideally suited for surface preparation and finishing works.An angle grinder is a powerful tool that is primarily used to cut, grind, and polish metal surfaces. However, adding a nylon brush to the angle grinder enhances its functionality, making it suitable for specialized purposes. The nylon brush is designed to access tight and hard-to-reach areas of metal surfaces that traditional sandpaper or wire brushes cannot reach. It is also effective in cleaning and deburring stainless steel, aluminum, and other delicate surfaces without scratching them.There are various types of nylon brushes for angle grinders, and the brush choice will depend on the material to be worked on, the finish required, and the angle grinder's speed and power capacity. For instance, the coarse mesh brush is ideal for removing rust, paint, and other stubborn stains from metal surfaces and grinding welded joints. On the other hand, the fine mesh brush provides a smooth finish on metal surfaces. It is suitable for tasks such as surface preparation before painting, polishing, or applying a protective coating.While it is essential to choose the right brush for your angle grinder, choosing a high-quality brand is equally important. One such brand is {Brand Name Removed}, a global leader in the production of industrial brushes. They have over 150 years of experience in the manufacturing of quality brushes, and their nylon brushes for angle grinders are no exception.Their nylon brushes for angle grinders are made from high-quality polyamide filaments that are durable, heat-resistant, and have excellent bending recovery properties. They have a wide range of brushes available for different types of jobs, including the coarse mesh brush, fine mesh brush, crimped wire brush, and many more. These brushes are easy to install and designed to fit most angle grinders, providing a quick and efficient cleaning or finishing solution.{Brand Name Removed} nylon brushes for angle grinders are also environmentally friendly. They are designed to last longer, reducing the need for frequent replacement, and are recyclable, reducing waste. This makes them an ideal choice for environmentally conscious industries.In conclusion, the nylon brush for an angle grinder is an essential tool for any industrial setting that requires surface finishing, preparation, or cleaning. When combined with high-quality brands such as {Brand Name Removed}, the nylon brush for angle grinders becomes a valuable asset in any work setting. Their durability, performance, and versatility make them an industry-standard in the manufacturing and construction sectors, where precision and quality matter most. With the right brush choice and the right brand, expect to work more efficiently and with greater precision.