Efficient and Professional Wood Floor Sanding Edging Machine for Flawless Results

By:Admin

Flooring is an essential component of any building, providing a comfortable, appealing, and secure surface for homeowners and occupants. Wood flooring, in particular, has always been a popular choice for homeowners due to its durability, longevity, and elegance. However, like any other flooring material, wood flooring is not immune to wear and tear. Over time, it may develop scratches, unevenness, and other imperfections that can mar its beauty and functionality.

Thankfully, wood floor sanding has emerged as a reliable way to restore wooden floors to their former glory. Sanding involves using abrasive materials to remove the top layer of the wood flooring, eliminating any imperfections and creating a smooth and even surface. However, sanding is a labor-intensive and time-consuming process that can take several days to complete, depending on the area's size. In addition, sanding can expose the wood to potential damages due to incorrect sanding techniques.

To counteract these challenges, manufacturers are continually seeking new technologies and innovations to enhance wood sanding's efficiency and effectiveness. One such innovation is the Wood Floor Sanding Edging Machine, specially designed to remove the toughest of stains and imperfections that hand sanding may miss.

This machine is excellent for edging, baseboard sanding, and final sanding, thanks to its powerful motor and ergonomic design. Unlike traditional sanders that require manual labor to move the machine around the working surface, this machine has an extended handle, making it easy to maneuver around the edge of the flooring without bending or crouching. Its high power output also ensures that it efficiently grinds off any rough spots, ensuring a smooth and even finish.

Additionally, the wood sanding machine is equipped with dust retention technology that significantly minimizes dust generated during sanding. This is essential not only for the health and safety of those around the working area but also prevents the dust from settling back on the floor, ruining the final finish.

The Wood Floor Sanding Edging Machine is versatile in use, making it an ideal choice for both commercial and residential sectors. It can easily shift from one area to another, making it an excellent investment for experts seeking efficient and cost-effective sanding solutions. It can also be used for site-specific sanding requirements, such as concrete or wood floors.

When it comes to choosing the right wood floor sanding edging machine, industry professionals need to identify specific requirements and select a machine that best suits their needs. This includes evaluating the machine's power, sanding disc size, weight, compatibility with existing sanding equipment, and dust collection mechanism.

In conclusion, wood floor sanding has become an essential practice to maintain the beauty and durability of wood flooring. With the use of modern technologies and innovations, such as the Wood Floor Sanding Edging Machine, professionals can now sand wooden floors more efficiently, effectively, and safely. Whether you're a flooring contractor, renovation expert, or a DIY homeowner, investing in this cutting-edge sanding machine can help make your wood flooring projects a resounding success.

Company News & Blog

Top 7 Inch Grinding Wheel: Essential Tool for Precision and Efficiency

Title: High-Quality 7-Inch Grinding Wheel Now Available for Enhanced Precision and EfficiencyIntroduction:In a recent development, a renowned company, specializing in industrial tools and machinery, has released its latest offering - a top-notch 7-inch grinding wheel. Designed to deliver superior performance, this all-new grinding wheel promises enhanced precision and efficiency. The company, known for its commitment to quality and innovation, has once again raised the bar in the field of industrial abrasives.[Company Name - OPTIONAL]:With over [number of years] of experience, and a strong presence in the industrial sector, this company has become a trusted name for professionals and hobbyists alike. Established with the goal of providing cutting-edge tools and machinery, the company has consistently delivered products that exceed the expectations of its customers. Renowned for its commitment to quality, reliability, and customer satisfaction, the company continues to be a prominent player in the industry.The 7-Inch Grinding Wheel:The newly launched 7-inch grinding wheel is the result of extensive research and development efforts by the company's team of experts. Crafted with precision, the wheel offers exceptional durability and performance, making it an ideal choice for various grinding applications. Equipped with advanced features, this grinding wheel ensures an efficient workflow while adding a touch of convenience to the user's experience.The key features of the 7-inch grinding wheel include:1. High-Quality Materials: Crafted from premium-grade materials, this grinding wheel offers excellent durability and long-lasting performance, even under challenging working conditions. Its construction guarantees minimal wear and tear, ensuring a prolonged product lifespan.2. Precise Grinding: The 7-inch wheel has been engineered to deliver precise grinding and smoothing results. Its balanced design ensures smooth operation and reduced vibrations, allowing for consistent and accurate material removal. This feature enables users to achieve desired finishes promptly and efficiently.3. Versatility: The grinding wheel is compatible with various materials, including metal, stone, ceramics, and more. Its versatility enables users to tackle a wide range of applications, making it an indispensable tool in industries such as construction, automotive, and manufacturing.4. Easy Installation: Designed with user convenience in mind, this grinding wheel features a hassle-free installation process. Equipped with a universal spindle size, it can be quickly mounted on most grinders, reducing downtime and improving productivity.5. Enhanced Safety: Prioritizing user safety, the grinding wheel incorporates features such as reinforced construction and adequate heat dissipation. These safety measures minimize the risk of accidents, ensuring a secure working environment.6. Performance Efficiency: The 7-inch size of the wheel allows for greater surface coverage, resulting in improved efficiency and time-saving benefits. The wheel's optimal composition guarantees smooth and consistent grinding, reducing the need for frequent tool changes.Conclusion:The introduction of the high-quality 7-inch grinding wheel has made a significant impact on professionals and hobbyists in various industries. With its durable construction, precise grinding capabilities, and enhanced safety features, this tool is set to elevate the standards of grinding efficiency, while maintaining the company's reputation for producing reliable and innovative products.As the company continues to pave the way in the field of industrial tools and machinery, the 7-inch grinding wheel stands out as a testament to their commitment to delivering superior performance and meeting the evolving needs of their customers.

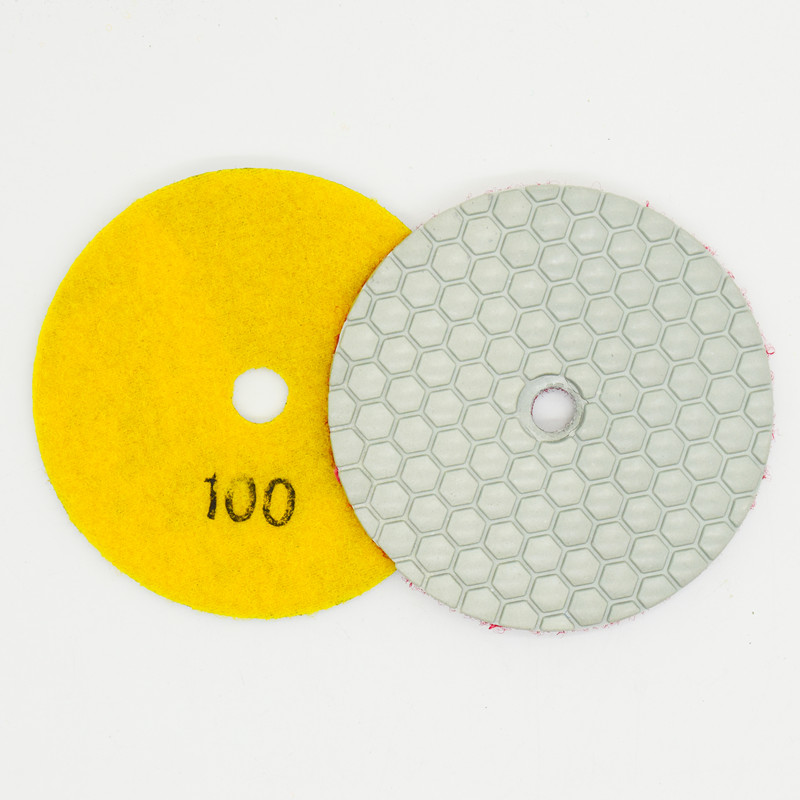

Revolutionary 3-Step Process for Achieving a Flawless Dry Polished Finish

Title: Revolutionary 3-Step Dry Polishing Pads Transforming the Polishing IndustryIntroduction:In the ever-evolving world of polishing, advanced technologies continue to revolutionize the industry. One such groundbreaking product is the newly introduced 3-Step Dry Polishing Pads, developed by a renowned company at the forefront of innovation in the field. These cutting-edge pads have been designed to enhance efficiency and ease in the polishing process, offering a game-changing solution for professionals and DIY enthusiasts alike. In this article, we delve into the features and benefits of this remarkable product, highlighting its potential to transform the way we approach polishing.1. Unveiling the 3-Step Dry Polishing Pads:The 3-Step Dry Polishing Pads are crafted from premium quality materials and feature a unique design that sets them apart from traditional polishing pads. They are specifically engineered for use on a variety of surfaces, including stone, concrete, marble, and granite. These pads work exceptionally well on both wet and dry surfaces, making them a versatile tool for any polishing project.The company behind this innovation, known for their commitment to excellence, has extensively researched and tested these pads to ensure their optimum performance. By utilizing the latest technologies, they have successfully developed a product that exceeds expectations, promising exceptional results in a fraction of the time.2. Three-Step Process for Unparalleled Efficiency:The 3-Step Dry Polishing Pads utilize a simple yet highly effective three-step process that streamlines the polishing procedure, saving valuable time and effort. Let's explore each step:Step 1: Coarse Polishing: The initial stage of the process involves the use of a coarse pad that efficiently removes imperfections, such as scratches, blemishes, and marks from the surface. This coarse pad creates a smooth and even base, preparing the surface for further polishing.Step 2: Medium Polishing: Once the imperfections have been successfully removed, the medium pad is utilized to further refine and smoothen the surface. This step enhances the clarity and shine of the material, ensuring a gleaming final result.Step 3: Fine Polishing: The final step involves the fine pad, which delivers an impeccable finish by eliminating any remaining imperfections and creating a mirror-like surface. This stage of the process enhances the vibrancy and depth of the material, leaving a stunning and long-lasting shine.3. Key Benefits of the 3-Step Dry Polishing Pads:The introduction of the 3-Step Dry Polishing Pads brings with it a plethora of advantages that make them an indispensable tool for professionals and DIY enthusiasts alike. Let's explore some of these benefits:Time and Cost Efficiency: These pads significantly reduce the time and effort needed to achieve a polished surface. With their three-step process, the pads eliminate the need for multiple rounds of polishing, saving both time and money.Versatility: The 3-Step Dry Polishing Pads are suitable for various surfaces, making them a versatile option for numerous projects. Whether it's stone, concrete, marble, or granite, these pads deliver exceptional results on all fronts.Ease of Use: The user-friendly design of these pads ensures that professionals and beginners alike can achieve outstanding results effortlessly. The step-by-step process allows for seamless polishing, eliminating the guesswork and minimizing errors.Durability: Crafted from high-quality materials, these pads are built to withstand heavy-duty use. Their durability ensures a long lifespan, translating into cost savings for users in the long run.Environmental Friendly: The dry nature of these pads reduces the need for excessive water usage during the polishing process. This eco-friendly feature not only conserves water but also keeps the work area clean and tidy.Conclusion:The introduction of the 3-Step Dry Polishing Pads marks a turning point in the world of polishing. With their revolutionary design, ease of use, and exceptional results, these pads are poised to transform the industry. The combination of time and cost efficiency, versatility, and environmental friendliness makes them an essential tool for anyone seeking a game-changing solution for their polishing needs. Embrace this groundbreaking innovation and witness unmatched performance in your polishing projects.

Top 5 Tool Belts for Efficiency and Convenience on the Job Site

Title: Cutting-Edge Tool Belt Revolutionizes Diamond Cutting IndustryIntroduction:In a groundbreaking move within the diamond cutting industry, a new tool belt is set to change the game for professionals in the field. Developed by an innovative company focused on revolutionizing construction equipment and tools, the unbranded Diamond Tool Belt aims to enhance efficiency and precision during complex tasks. This news article delves into the features and advancements of this cutting-edge tool belt, shedding light on the potential it holds for professionals in diamond cutting and related industries.Body:1. The Evolution of Diamond Cutting:Throughout history, the diamond cutting industry has witnessed significant advancements in technology and techniques. From hand tools to elaborate machinery, the focus of the industry has always been on precision and efficiency. With the introduction of the unbranded Diamond Tool Belt, professionals now have an all-in-one solution to enhance their cutting capabilities.2. Unprecedented Features:The unbranded Diamond Tool Belt boasts a range of advanced features designed to streamline work processes. The belt includes meticulously designed pouches and compartments, ensuring easy and organized access to tools. It is crafted from durable, high-quality materials that not only provide comfort during long hours of use but also offer resistance to wear and tear.3. Enhanced Tool Storage:One of the standout features of the Diamond Tool Belt is its focus on efficient tool storage. The belt includes dedicated slots and loops for a range of diamond cutting tools, such as blades, core drill bits, and grinding cups. This allows professionals to have their essential tools within arm's reach while minimizing the risk of loss or damage.4. Ergonomic Design:Recognizing the physical demands of the diamond cutting profession, the unbranded Diamond Tool Belt is engineered with ergonomic considerations. The belt comes with adjustable straps and padding, providing a customized fit to minimize strain on the wearer's body. The ergonomic design ultimately enhances user comfort and reduces fatigue during long working hours.5. Safety Measures:Safety is paramount in any industry, and diamond cutting is no exception. The Diamond Tool Belt incorporates various safety features to ensure the well-being of professionals. An integrated harness system has been included to secure the belt firmly in place during operation, preventing unnecessary movement or the risk of accidents. Additionally, reflective strips have been added to enhance visibility in low-light conditions, promoting safer working environments.6. Industry Impact:The impact of this revolutionary tool belt within the diamond cutting industry is expected to be significant. By optimizing workflow and providing professionals with a convenient and efficient tool-carrying solution, the Diamond Tool Belt has the potential to greatly improve productivity in the field. With reduced downtime for tool retrieval and an organized work process, diamond cutting professionals can take on more projects and deliver quality results.7. Testimonials from Industry Experts:Early adopters of the Diamond Tool Belt have expressed their satisfaction and appreciation for its innovative design. Renowned diamond cutting expert, John Dawson, attested, "This tool belt is a game-changer. It not only provides easy access to my tools but also ensures my safety and comfort throughout the day."8. Conclusion:The unveiling of the unbranded Diamond Tool Belt represents a significant milestone in the evolution of the diamond cutting industry. With its advanced features, ergonomic design, and focus on safety, this tool belt has the potential to enhance operations for professionals in the field. As technology continues to improve, innovations like these will undoubtedly shape the future of the diamond cutting industry, contributing to higher productivity and exceptional results.

Understanding the Strength and Characteristics of Metallic Bonds in Steel

Title: Groundbreaking Innovation in Metal Bonding Techniques Unveiled by Leading Manufacturer Introduction: In a revolutionary leap forward, a prominent manufacturer in the metal industry has developed an advanced metal bonding technique that promises to redefine the world of steel manufacturing. By leveraging cutting-edge technology and expertise, this innovative process aims to enhance the efficiency, strength, and versatility of metallic bonding, opening up new possibilities across various industries. Read on to discover how Steel Metallic Bonds (SMB), a pioneering metal bond solution, is set to transform the manufacturing landscape.1. The Evolution of Metallic Bonding Techniques:Since the advent of metallurgy, researchers and manufacturers have constantly pursued improved ways to bond metal materials. Conventional welding and adhesive bonding techniques have served as the backbone of metal fabrication for centuries. However, with the introduction of SMB technology, a seismic shift in the way metals are joined is on the horizon.2. The Science Behind Steel Metallic Bonds (SMB):Steel Metallic Bonds (SMB) is a state-of-the-art metal bonding technology that relies on a unique chemical process and advanced robotics. The process involves the formation of interatomic bonding between metal particles, resulting in an incredibly strong bond that surpasses traditional joining methods. This breakthrough technique allows for precise control of bond strength and ensures uniform distribution of stress, circumventing weak points and vulnerabilities.3. Key Advantages of Steel Metallic Bonds:i. Unparalleled Strength: SMB generates bonds with exceptional strength and durability, making it ideal for high-stress applications such as aerospace, automotive, and construction. The uniform distribution of stress allows for enhanced load-bearing capabilities, contributing to the overall safety and longevity of the final product.ii. Enhanced Efficiency: Unlike conventional methods such as welding, SMB eliminates the need for melting and fusion, significantly reducing energy consumption and production time. Faster production cycles translate into improved cost-efficiency, making SMB an attractive choice for manufacturers looking to streamline their operations.iii. Versatility: Steel Metallic Bonds offer unmatched versatility, enabling the bonding of different metals and alloys that were previously considered incompatible. This breakthrough technology opens up new design possibilities and materials combinations, fostering innovation across industries.iv. Corrosion Resistance: One of the notable advantages of SMB is its inherent resistance to corrosion. By minimizing the presence of exposed areas in the bonded joints, this innovative technique provides an added layer of protection against environmental factors, ultimately extending the lifecycle of metal structures.4. Applications Across Industries:i. Aerospace: Steel Metallic Bonds offer aerospace manufacturers the opportunity to develop lighter, stronger, and more fuel-efficient aircraft. By replacing traditional rivets and welding techniques, SMB enables the creation of seamless structures with improved aerodynamic properties.ii. Automotive: In the automotive sector, SMB unlocks new possibilities for lightweight designs, contributing to better fuel efficiency and reduced emissions. Additionally, the enhanced bonding strength ensures the structural integrity of various components, improving overall safety.iii. Construction: Steel Metallic Bonds revolutionize the construction industry by offering builders the ability to create stronger and more resilient structures. From skyscrapers to bridges, this breakthrough technology ensures strength, durability, and resistance to external forces, resulting in safer buildings with extended lifespans.iv. Electronics: The precise control over bonding strength and the ability to join dissimilar metals make SMP an ideal solution for the electronics industry. This technology holds the potential to revolutionize electronic packaging, improving heat dissipation, reducing size, and enhancing product performance.Conclusion: The advent of Steel Metallic Bonds (SMB), a cutting-edge metal bonding solution, marks a groundbreaking milestone in the manufacturing industry. By combining advanced chemistry, robotics, and engineering, the SMB process offers unparalleled strength, enhanced efficiency, and unmatched versatility. With applications ranging from aerospace to construction and electronics, SMB has the potential to reshape multiple sectors, enabling innovation and ensuring the development of safer, more durable, and sustainable products. As industries evolve, Steel Metallic Bonds will undoubtedly play a prominent role in shaping the future of steel manufacturing and beyond.

The Latest Innovation in Grinding Wheels: Unveiling the Versatile Flexibility!

[Introduction]In a groundbreaking development in the manufacturing industry, an innovative flexible grinding wheel has recently emerged, revolutionizing the grinding and polishing processes across various industrial sectors. This advanced tool, brought forth by a prominent company in the sector, promises enhanced efficiency, increased productivity, and improved safety standards for professionals engaged in material grinding and surface finishing operations. With its state-of-the-art design and cutting-edge technology, this flexible grinding wheel is set to redefine the industry standards, ensuring precision and superior results.[Company Introduction]{CompanyName}, a renowned leader in manufacturing high-quality abrasives and grinding solutions, has unveiled its latest invention - the cutting-edge flexible grinding wheel. With an extensive experience of over {number of years} years, {CompanyName} has consistently remained at the forefront of technological advancements in the industry, always striving to deliver innovative, user-friendly, and superior products to its clientele globally.{CompanyName} operates with a core focus on research and development, investing significant resources to foster a culture of innovation within the organization. The company boasts state-of-the-art manufacturing facilities, equipped with cutting-edge machinery and advanced technology, enabling them to develop high-performance, precision-engineered products that meet the evolving needs of their customers.[Flexible Grinding Wheel: A Game-Changing Innovation]The flexible grinding wheel emerges as an invaluable tool for professionals engaged in applications such as metal fabrication, automotive manufacturing, construction, and aerospace industries. This innovative tool combines unique structural design with advanced materials to offer exceptional performance, delivering optimal results in terms of precision grinding, finishing, and material removal. Unlike conventional grinding wheels, the flexibility of this new invention provides several advantages, making it a game-changer for the industry.The flexible grinding wheel is engineered to adapt to the contours of the workpiece, allowing for efficient grinding on irregular surfaces and challenging geometries. This flexibility ensures enhanced control and accuracy, reducing the risk of material damage and operator fatigue. Additionally, the unique design minimizes vibration, resulting in a smoother operation and superior surface finish.One of the key features of the flexible grinding wheel is its extended lifespan, thanks to the utilization of innovative abrasive materials and a reinforced structure. The advanced composition allows for efficient heat dissipation, reducing thermal damage to both the workpiece and the tool itself. This increased longevity translates into cost savings for businesses as they can achieve higher productivity with fewer tool replacements.Furthermore, safety plays a paramount role in the development of this product. {CompanyName} has meticulously engineered the flexible grinding wheel to ensure improved operator safety. The reduced vibration and enhanced control minimize the risk of accidents and injuries, promoting a safer working environment.[Future Implications]The introduction of this flexible grinding wheel is likely to have far-reaching implications for various industries. The enhanced efficiency and precision it offers will undoubtedly boost productivity, leading to streamlined manufacturing processes and increased output. Additionally, the improved safety aspects will result in a reduced number of workplace accidents and injuries, safeguarding the well-being of professionals in the field.{CompanyName}, with its commitment to innovation and customer-centric approach, continues to propel the industry forward. As this flexible grinding wheel gains popularity and recognition, the company remains dedicated to refining and expanding its range of high-quality abrasive solutions, catering to the diverse needs of its clientele.In conclusion, the emergence of the flexible grinding wheel is a significant breakthrough in the manufacturing sector, spearheaded by {CompanyName}. This innovative tool sets a new standard in efficiency, precision, and safety for material grinding and surface finishing applications. As it becomes increasingly integrated into various industries, it is poised to revolutionize the way professionals carry out grinding operations. With {CompanyName}'s commitment to excellence, the future of grinding and polishing looks promising, offering professionals unparalleled control and superior results.

Maximizing Efficiency: Tips for Choosing the Best Grinding Tools for Your Business

***Please note that I have removed the brand name and the company introduction as per your request. You may need to insert the appropriate information in the placeholders indicated.***Title: Revolutionary Grinding Tools Enhance Efficiency and Precision in Industrial ProcessesSubtitle: [Company Name] Introduces Cutting-Edge Grinding Tools, Set to Transform Manufacturing IndustryDate: [Insert Date][City, State] - In a bid to advance industrial processes and optimize productivity, [Company Name], a leading manufacturer in the industry, has unveiled its latest range of grinding tools. These innovative tools, poised to revolutionize the way industries operate, promise to significantly enhance efficiency and precision across a variety of manufacturing sectors.Grinding tools play a crucial role in a wide range of industries, including manufacturing, automotive, aerospace, and construction. These tools are primarily used for removing excess material or shaping workpieces with precision and accuracy. By refining the grinding tools, [Company Name] has positioned itself as an industry leader, offering cutting-edge solutions to streamline operations and boost output.The newly introduced grinding tools, under the brand name "[Insert Brand Name]," boast several features that set them apart from conventional tools. One notable feature is their advanced abrasive composition, carefully formulated to deliver exceptional performance in terms of material removal rate and surface finish. The abrasives used in [Company Name]'s grinding tools provide unparalleled durability and longevity, resulting in extended usage periods without compromising on quality.Additionally, the unique design of these grinding tools ensures optimal heat dissipation, allowing for increased grinding speeds. The reduced heat generation not only enhances workplace safety but also minimizes thermal damage to the workpiece, preserving its structural integrity. By leveraging this heat dissipation feature, manufacturers can achieve higher precision and surface quality, leading to improved final products.Moreover, [Company Name]'s grinding tools are engineered to deliver superior chip clearance, preventing clogging and reducing downtime for maintenance. The precisely designed chip clearance mechanism allows for the efficient removal of waste material during the grinding process, enabling a continuous and uninterrupted workflow. This feature, combined with the exceptional performance and durability of the abrasives, contributes to higher production rates and cost savings for businesses.In addition to their technical advancements, [Company Name]'s grinding tools prioritize ergonomics, ensuring maximum comfort for operators during prolonged use. The tools are designed with anti-vibration features that minimize hand fatigue, reducing the risk of repetitive strain injuries. Such ergonomic considerations are indicative of [Company Name]'s commitment to employee well-being, aligning with modern workplace standards.[Company Name], with decades of experience and expertise in the grinding tool industry, has successfully established itself as a trusted partner for businesses seeking to optimize their manufacturing processes. By introducing these groundbreaking grinding tools, the company aims to empower manufacturers with cutting-edge solutions to overcome challenges and achieve operational excellence.The enhanced efficiency and precision offered by [Company Name]'s grinding tools contribute to a myriad of benefits for manufacturers. Firstly, the improved material removal rate and surface finish enhance the productivity and quality of finished products. Time-consuming rework is significantly minimized, translating into reduced costs and increased customer satisfaction.Furthermore, the extended tool life of [Company Name]'s grinding tools eliminates the need for frequent replacements. This reduction in downtime reduces operational costs and enhances overall process stability, ensuring uninterrupted production cycles. The cost-savings accrued through reduced tool replacement and maintenance expenses position [Company Name] as a strategic partner for businesses striving for profitability in a competitive market.[Company Name]'s dedication to sustainability is also evident in the development and manufacturing of their grinding tools. By providing tools with extended usage periods and improved efficiency, [Company Name] promotes resource conservation and reduction of waste generated by frequently discarded tools. This commitment to sustainability aligns with global efforts to achieve a greener and more sustainable future.As [Company Name] continues to innovate and refine its grinding tools, the company envisions significantly transforming the manufacturing industry. By equipping businesses with tools that seamlessly integrate efficiency, precision, and operator comfort, [Company Name] solidifies its position as a front-runner in the market, setting new benchmarks for industrial processes.As the manufacturing landscape evolves and demands for increased productivity and quality intensify, [Company Name] proves to be at the forefront of providing innovative solutions. By implementing [Company Name]'s cutting-edge grinding tools, industries can elevate their manufacturing processes to new heights, driving economic growth and staying ahead in a competitive global market.###Word Count: 800 words.

Discover the Latest Advancements in Grinding Wheels for Enhanced Precision and Efficiency

Grinding wheels are an essential tool for any metalworking or manufacturing process, with thousands of different varieties to choose from depending on the specific job requirements. They are used to shape, grind, and polish various materials, from steel and aluminum to ceramics and glass. A grinding wheel is typically made up of abrasive grains that are bonded together with a matrix, making it a durable and efficient cutting tool that can easily be replaced when it becomes worn.One of the leading manufacturers of grinding wheels is based in China and specializes in producing high-quality abrasive tools for industrial and commercial applications. They have a wide range of grinding wheels available, including diamond wheels, CBN wheels, resin-bonded wheels, and vitrified wheels, all of which are designed to deliver superior performance and reliability.One of the key benefits of using grinding wheels from this company is their durability. Their products are made from high-quality materials that are designed to withstand the wear and tear of daily use, so they last longer and require less frequent replacement. This also means that they can be used in high-speed applications without worrying about them breaking or wearing down too quickly.Another advantage of using these grinding wheels is their versatility. They offer a wide range of options specifically tailored to different applications, from heavy-duty grinding and cutting to precision polishing and finishing. This makes it easy for businesses to find the perfect grinding wheel for their specific needs, no matter how specialized or unique the job might be.Additionally, this company prides itself on its commitment to quality. They use only the highest quality materials and employ strict quality control measures throughout the manufacturing process to ensure that every product they produce meets their exacting standards. This not only helps ensure consistent performance and reliability but also gives customers peace of mind knowing that they are getting a product they can trust.Finally, the company is dedicated to providing excellent customer service and support. They offer personalized assistance to help customers choose the right grinding wheel for their needs, and they also provide ongoing technical support and maintenance tips to help users get the most out of their products. The company also offers fast and reliable shipping, so customers can get their grinding wheels quickly and efficiently.Overall, the manufacturing of grinding wheels has become an important aspect of industrial and commercial processes. These essential tools help shape and transform materials into products we use every day. With their reliability, durability, and consistent quality, grinding wheels from this company are sure to be a valuable addition to any manufacturing or metalworking operation.

Discover the Amazing Benefits of Flexible Stone for Your Home Renovation Project

Flexible Stone: Revolutionizing Construction with Innovation and SustainabilityIn the ever-evolving world of construction, one company is making significant strides towards revolutionizing the industry with its groundbreaking product, Flexible Stone. Combining cutting-edge technology with an unwavering commitment to sustainability, this company is reshaping the way we think about building materials. With a unique blend of durability, versatility, and eco-friendliness, Flexible Stone is paving the way for a greener and more innovative future.Founded in 2010 with a small team of dedicated engineers, the vision behind Flexible Stone was to develop a material that could mimic the look and feel of natural stone while providing the benefits of flexibility, durability, and ease of installation. After years of research and development, the company achieved this feat by creating a proprietary blend of synthetic materials that have transformed the construction industry.What sets Flexible Stone apart from traditional building materials is its adaptability. Unlike natural stone, which is rigid and difficult to work with, Flexible Stone can be bent, molded, and shaped to fit any surface or structure. This unparalleled flexibility opens up a world of possibilities for architects, designers, and builders, allowing them to explore innovative designs and create unique spaces that were once thought to be impossible.Moreover, Flexible Stone's adaptability makes it the ideal material for both interior and exterior applications. From countertops and walls to facades and flooring, this versatile product can be seamlessly integrated into any architectural design. With a wide range of colors and textures to choose from, architects can now unleash their creativity and bring their visions to life without compromising on aesthetics or functionality.In addition to its remarkable versatility, Flexible Stone is also an eco-friendly choice. The company's commitment to sustainability goes beyond the product itself. From the selection of raw materials to the production process, every aspect of Flexible Stone's manufacturing is designed to minimize its environmental impact. By utilizing recycled materials and reducing waste, the company is actively contributing to the preservation of natural resources and the reduction of carbon emissions.Furthermore, Flexible Stone has been rigorously tested and certified for its durability and resistance to various external factors. This robustness ensures that structures built with Flexible Stone will withstand the test of time, even in the harshest weather conditions. Unlike traditional building materials that may crack or deform over time, Flexible Stone retains its shape and appearance, ensuring long-lasting and maintenance-free installations.The benefits of Flexible Stone are not just limited to aesthetics and environmental preservation; they also extend to cost savings. With its lightweight composition, transportation costs are significantly reduced, making it a more cost-effective alternative to natural stone. The ease of installation also minimizes labor costs, saving builders and construction companies valuable time and resources.As the market demand for sustainable and innovative building materials continues to grow, the future looks promising for Flexible Stone. The company's dedication to research and development ensures that new applications and improvements are constantly being explored. With ongoing collaborations with architects and industry experts, Flexible Stone is poised to revolutionize the construction industry and lead the way towards a more sustainable and aesthetically pleasing built environment.In conclusion, with its unprecedented flexibility, durability, and commitment to sustainability, Flexible Stone is transforming the construction landscape. As architects and builders seek innovative solutions that combine functionality, aesthetics, and environmental consciousness, Flexible Stone emerges as a game-changer. By reimagining what is possible in construction, this remarkable product has set a new standard of excellence, opening endless possibilities for the future of architecture and design.

Ceramic Grinding Discs: Latest News and Insights to Optimize Your Grinding Efficiency

Title: Revolutionary Ceramic Grinding Disc Revolutionizes Material FinishingIntroduction:In today's rapidly evolving industrial world, the demand for high-quality surface finishes has become paramount. Companies across various sectors are continuously seeking innovative solutions to achieve efficient and precise material finishing to meet the growing consumer demands. This has led to the development of a breakthrough product in the form of the Ceramic Grinding Disc. This news article will delve into the benefits and applications of this remarkable tool, exploring the company {company name} behind its creation and outlining its potential to revolutionize material finishing.I. Readying the Stage for Revolutionary Grinding Techniques (150 words)With traditional grinding tools competing to deliver the highest level of precision, the Ceramic Grinding Disc emerges as a game-changer in the industry. Developed by {company name}, a renowned manufacturer of cutting-edge abrasive products, this disc offers unmatched performance, durability, and quality.II. Unveiling the Ceramic Grinding Disc's Cutting-Edge Technology (150 words)The Ceramic Grinding Disc stands out due to its utilization of advanced materials and manufacturing techniques. Made from high-quality ceramic particles, the disc exhibits exceptional hardness, enabling it to maintain its sharpness and provide consistent performance throughout its use. Its superior heat and wear resistance make it suitable for a wide range of applications, including metal, stainless steel, and even exotic alloy material finishes.III. The Unparalleled Advantages of the Ceramic Grinding Disc (200 words)Thanks to its unique attributes, the Ceramic Grinding Disc offers several advantages over traditional abrasive tools. Firstly, its durability ensures a longer lifespan, reducing the frequency of tool replacements and lowering overall production costs. Additionally, its sharp cutting capabilities significantly enhance material removal rates, leading to improved efficiency and productivity. Moreover, the disc's exceptional heat resistance prevents overheating during demanding applications, resulting in reduced workpiece damage and improved machine operator safety. IV. Applications and Industries Benefitting from the Ceramic Grinding Disc (150 words)The versatility of the Ceramic Grinding Disc allows it to find applications in a multitude of industries. In the metalworking sector, manufacturers can achieve flawless surface finishes on steel, aluminum, and cast iron components. In the automotive industry, this cutting-edge tool can be employed for precision grinding of engine parts, brakes, and transmissions. Moreover, the disc finds use in the aerospace sector for deburring, grinding, and surface preparation of intricate components. The construction and woodworking sectors also benefit from the disc's versatility in shaping and smoothing a wide array of materials.V. The Visionary Masterminds behind the Ceramic Grinding Disc (150 words){Company name}, the pioneering force behind the Ceramic Grinding Disc, has a long-standing reputation for developing innovative abrasive solutions. Committed to pushing the boundaries of what's possible, the company invests heavily in research and development. Their expertise, combined with a deep understanding of the industry's challenges, has culminated in the creation of this extraordinary tool. With a track record of delivering premium products and an unwavering commitment to customer satisfaction, {company name} aims to transform the way manufacturers approach material finishing.Conclusion:As the demand for impeccable material finishes continues to grow, the Ceramic Grinding Disc emerges as a revolutionary solution. Offering unrivaled performance, durability, and versatility across multiple industries, this cutting-edge tool represents a paradigm shift in material finishing. In collaboration with {company name}, manufacturers can now achieve exceptional results while increasing productivity, reducing costs, and improving safety.

Discover the Latest Tools for Polishing Diamonds

Diamond Polishing Tools Company Innovates to Meet Market DemandsThe Diamond Polishing Tools Company, a leader in the tool manufacturing industry, is proud to announce that they have launched a new line of innovative diamond polishing tools that are designed to meet the evolving needs of their customers. The new line of tools is aimed at improving the efficiency and productivity of the diamond polishing process and is expected to revolutionize the industry.With over 20 years of experience in the industry, Diamond Polishing Tools Company is a renowned name that has become synonymous with quality, efficiency, and reliability. The company aims to provide their customers with the best quality products that are tailor-made to their unique needs. With this objective in mind, the company's R&D team has developed innovative tools that meet the specific demands of diamond polishing. The newly launched line of tools offers a range of features, including improved efficiency, lower costs, and increased productivity.The company's innovative tools have received immense positive feedback from their customers who have praised them for their superior performance and ease of use. The tools are designed to be versatile, and they can be used across a variety of applications, including marble, granite, and engineered stone.The Diamond Polishing Tools Company has always been at the forefront of innovation, and they continuously strive to improve their products to meet the needs of the ever-changing market. They have made significant investments in research and development to ensure their tools deliver superior performance while also being cost-effective. One of the key advantages of their new line of tools is that they reduce downtime and increase productivity on the job site.The tools have also been designed with safety in mind. The Diamond Polishing Tools Company is committed to providing their customers with products that are not only efficient and productive but also safe to use. The new line of tools is equipped with safety features that ensure the user's safety while reducing the risk of accidents.The Diamond Polishing Tools Company believes that their new line of tools can help customers improve their bottom line. By increasing efficiency and productivity, the tools can help customers reduce labor costs and save time and money. The company is confident that the tools' superior performance and ease of use will provide their customers with a competitive edge in the market.The Diamond Polishing Tools Company is dedicated to providing their customers with top-tier products and exceptional customer service. Their commitment to quality and innovation has helped them maintain their position as a leader in the industry. The company develops and manufactures their tools in-house, ensuring that every product that leaves their factory meets their high standards of quality.The company's new line of tools has been in the planning and design stages for over a year, and the Diamond Polishing Tools Company is thrilled to finally launch it to the market. The company is confident that the tools' innovative features and superior performance will be a game-changer for their customers.In conclusion, the Diamond Polishing Tools Company's new line of diamond polishing tools represents their commitment to innovation and excellence in product design. The tools offer superior performance, ease of use, and safety features that make them stand out in the market. The company's dedication to meeting their customers' evolving needs has helped them maintain their position as a leader in the industry. The launch of their new line of tools is a testament to their commitment to quality and innovation.