Effective Grinding Brush for Metal Polishing – A Complete Guide

By:Admin

As a trusted name in the industry, Grinding Brush has been catering to the needs of a wide range of clients across different sectors including metalworking, woodworking, automotive, and construction. With their strong focus on research and development, the company has continuously been at the forefront of introducing cutting-edge solutions that meet the evolving demands of the market.

The newly introduced grinding brushes by Grinding Brush are manufactured using premium quality materials and advanced manufacturing techniques. This ensures that the brushes are capable of delivering exceptional performance and longevity, even in the most demanding working environments. The brushes are designed to be compatible with various types of machinery and can be used for applications such as deburring, surface preparation, cleaning, and finishing.

One of the key highlights of the new grinding brushes is their versatility and adaptability to different surfaces and materials. Whether it's metal, wood, or composite materials, the brushes are engineered to effectively remove burrs, scale, rust, and other surface imperfections, while also providing a smooth and uniform finish. This level of versatility makes the brushes a valuable asset for companies dealing with a diverse range of materials and surface treatment requirements.

In addition to their outstanding performance, the grinding brushes are also designed with a focus on safety and environmental sustainability. They are equipped with features that minimize the generation of dust and reduce the risk of sparks, making them ideal for use in sensitive environments. Furthermore, the brushes are engineered to have a longer service life, which not only reduces the frequency of replacements but also contributes to lower overall waste generation.

For clients who have specific requirements, Grinding Brush also offers customized solutions to tailor the brushes according to their unique needs. This flexibility in product customization enables the company to cater to a wider spectrum of industrial applications and ensure that each client receives a solution that perfectly aligns with their operational requirements.

Apart from the product itself, Grinding Brush is also known for its reliable customer support and after-sales service. The company has a team of experienced professionals who are dedicated to providing technical assistance, installation guidance, and maintenance support to ensure that clients derive maximum value from their investment in grinding brushes.

The launch of the new line of grinding brushes underscores Grinding Brush's commitment to continuous innovation and delivering value-driven solutions to its clientele. With a strong track record of reliability, performance, and customer satisfaction, the company is well-positioned to further solidify its position as a leader in the industrial machinery and equipment sector.

The new grinding brushes are now available for purchase through Grinding Brush's extensive network of distributors and partners. Interested parties can also get in touch with the company directly to learn more about the product specifications, customization options, and pricing details.

In conclusion, Grinding Brush's latest innovation in the form of the new line of grinding brushes is set to make a significant impact in the industrial sector. With their focus on performance, durability, versatility, and environmental sustainability, the brushes are poised to become the go-to choice for companies looking to enhance their surface treatment capabilities and achieve superior results in their operations. As the industry continues to evolve, Grinding Brush is well-prepared to meet the changing needs of its clients and maintain its position as a leading provider of innovative industrial solutions.

Company News & Blog

Ceramic Grinding Discs: Latest News and Insights to Optimize Your Grinding Efficiency

Title: Revolutionary Ceramic Grinding Disc Revolutionizes Material FinishingIntroduction:In today's rapidly evolving industrial world, the demand for high-quality surface finishes has become paramount. Companies across various sectors are continuously seeking innovative solutions to achieve efficient and precise material finishing to meet the growing consumer demands. This has led to the development of a breakthrough product in the form of the Ceramic Grinding Disc. This news article will delve into the benefits and applications of this remarkable tool, exploring the company {company name} behind its creation and outlining its potential to revolutionize material finishing.I. Readying the Stage for Revolutionary Grinding Techniques (150 words)With traditional grinding tools competing to deliver the highest level of precision, the Ceramic Grinding Disc emerges as a game-changer in the industry. Developed by {company name}, a renowned manufacturer of cutting-edge abrasive products, this disc offers unmatched performance, durability, and quality.II. Unveiling the Ceramic Grinding Disc's Cutting-Edge Technology (150 words)The Ceramic Grinding Disc stands out due to its utilization of advanced materials and manufacturing techniques. Made from high-quality ceramic particles, the disc exhibits exceptional hardness, enabling it to maintain its sharpness and provide consistent performance throughout its use. Its superior heat and wear resistance make it suitable for a wide range of applications, including metal, stainless steel, and even exotic alloy material finishes.III. The Unparalleled Advantages of the Ceramic Grinding Disc (200 words)Thanks to its unique attributes, the Ceramic Grinding Disc offers several advantages over traditional abrasive tools. Firstly, its durability ensures a longer lifespan, reducing the frequency of tool replacements and lowering overall production costs. Additionally, its sharp cutting capabilities significantly enhance material removal rates, leading to improved efficiency and productivity. Moreover, the disc's exceptional heat resistance prevents overheating during demanding applications, resulting in reduced workpiece damage and improved machine operator safety. IV. Applications and Industries Benefitting from the Ceramic Grinding Disc (150 words)The versatility of the Ceramic Grinding Disc allows it to find applications in a multitude of industries. In the metalworking sector, manufacturers can achieve flawless surface finishes on steel, aluminum, and cast iron components. In the automotive industry, this cutting-edge tool can be employed for precision grinding of engine parts, brakes, and transmissions. Moreover, the disc finds use in the aerospace sector for deburring, grinding, and surface preparation of intricate components. The construction and woodworking sectors also benefit from the disc's versatility in shaping and smoothing a wide array of materials.V. The Visionary Masterminds behind the Ceramic Grinding Disc (150 words){Company name}, the pioneering force behind the Ceramic Grinding Disc, has a long-standing reputation for developing innovative abrasive solutions. Committed to pushing the boundaries of what's possible, the company invests heavily in research and development. Their expertise, combined with a deep understanding of the industry's challenges, has culminated in the creation of this extraordinary tool. With a track record of delivering premium products and an unwavering commitment to customer satisfaction, {company name} aims to transform the way manufacturers approach material finishing.Conclusion:As the demand for impeccable material finishes continues to grow, the Ceramic Grinding Disc emerges as a revolutionary solution. Offering unrivaled performance, durability, and versatility across multiple industries, this cutting-edge tool represents a paradigm shift in material finishing. In collaboration with {company name}, manufacturers can now achieve exceptional results while increasing productivity, reducing costs, and improving safety.

High-Quality Grind Stone for Sharpening and Polishing - A Must-Have Tool for DIY Enthusiasts

Diamond Grind Stone, a leading manufacturer of high-quality abrasive tools, has been revolutionizing the grinding industry with its innovative and top-notch products. With a commitment to providing superior quality and value to its customers, Diamond Grind Stone has become a trusted name in the industry.The company offers a wide range of grinding tools, including diamond grind stones, which are known for their exceptional performance and durability. These grind stones are designed to meet the needs of professionals in various industries, including metalworking, woodworking, and construction. With their precision-engineered diamond grit, Diamond Grind Stone's products deliver superior grinding performance and ensure a smooth and efficient finish.One of the key factors that set Diamond Grind Stone apart from its competitors is its dedication to research and development. The company invests heavily in advanced technology and cutting-edge manufacturing processes to continuously improve its products' quality and performance. This commitment to innovation has allowed Diamond Grind Stone to stay ahead of the curve and provide its customers with the best grinding solutions available in the market.Aside from its technical prowess, Diamond Grind Stone places a strong emphasis on customer satisfaction. The company's team of experts is always ready to assist customers in finding the right grinding tools for their specific needs. Whether it's a custom order or a technical inquiry, Diamond Grind Stone's customer support team is committed to providing exceptional service and ensuring that every customer is fully satisfied with their purchase.Furthermore, Diamond Grind Stone is dedicated to environmental sustainability. The company adheres to strict environmental regulations and ethical business practices to minimize its carbon footprint and promote responsible manufacturing. Additionally, Diamond Grind Stone seeks to reduce waste and optimize resource usage in its production processes, contributing to a more sustainable and eco-friendly industry.In line with its commitment to excellence, Diamond Grind Stone has recently unveiled its latest addition to its product line – the revolutionary {product name}. This innovative grind stone is designed to deliver unparalleled grinding efficiency and precision, making it an essential tool for professionals and hobbyists alike.The {product name} features an advanced diamond grit matrix that provides superior cutting performance and extended tool life. Its unique design and construction allow for effective material removal and a smooth surface finish, significantly reducing the time and effort required for grinding tasks. Moreover, the {product name} is engineered to withstand heavy-duty use, making it a reliable and long-lasting investment for any professional."We are excited to introduce the {product name} to our customers," said a spokesperson for Diamond Grind Stone. "This new addition to our product line represents our ongoing commitment to providing cutting-edge solutions that meet the evolving needs of our customers. With the {product name}, we aim to set a new standard for grinding performance and redefine what our customers can expect from their abrasive tools."The {product name} is now available for purchase through Diamond Grind Stone's extensive network of distributors and partners. The company encourages professionals and enthusiasts to experience the difference that this innovative grind stone can make in their grinding applications.As Diamond Grind Stone continues to push the boundaries of innovation and quality in the grinding industry, the company remains committed to its core values of excellence, integrity, and customer satisfaction. With its dedication to research and development, customer support, and environmental responsibility, Diamond Grind Stone is poised to lead the way in providing the best grinding solutions for professionals across various industries.

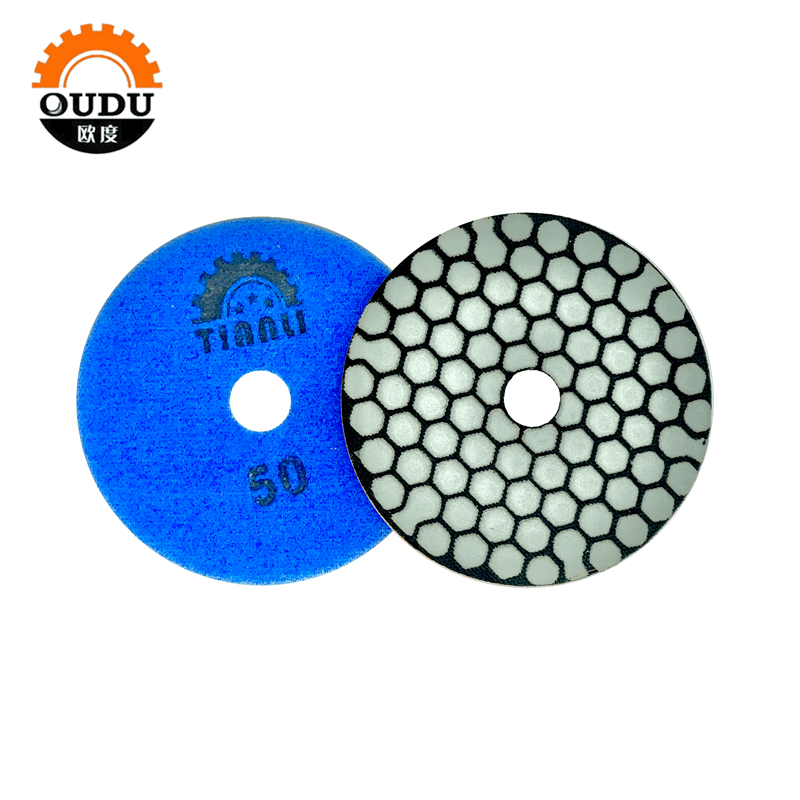

Effective Polishing Pads for Honeycomb Surfaces

Honeycomb Polishing Pads, a revolutionary new product in the world of concrete polishing, is changing the game for contractors and DIY enthusiasts alike. These innovative pads are designed to provide a superior finish on concrete surfaces, giving them a smooth and glossy look that is simply unmatched by traditional polishing methods. With their unique honeycomb pattern, these pads are able to remove marks and imperfections from the surface of the concrete, leaving behind a flawless finish that is sure to impress.{Company Name} is the leading manufacturer of Honeycomb Polishing Pads, and they have quickly become the go-to choice for contractors and DIYers alike. Their pads are known for their durability and versatility, making them an essential tool for anyone looking to achieve a professional-grade finish on their concrete surfaces.One of the key benefits of Honeycomb Polishing Pads is their ability to produce a high-gloss finish on concrete surfaces. This is achieved through the unique honeycomb pattern, which is designed to evenly distribute the pressure across the surface of the concrete. This results in a smooth and uniform finish that is free from any marks or imperfections, giving the concrete a sleek and polished look that is sure to impress.In addition to their high-gloss finish, Honeycomb Polishing Pads are also known for their durability and long-lasting performance. The pads are constructed from high-quality materials that are designed to withstand the rigors of concrete polishing, ensuring that they will continue to provide a superior finish for years to come.Another key advantage of Honeycomb Polishing Pads is their versatility. These pads are suitable for use on a wide range of concrete surfaces, including countertops, floors, and driveways. This makes them the perfect choice for contractors who work on a variety of projects, as well as for DIY enthusiasts who want to achieve a professional-grade finish on their own concrete surfaces.{Company Name} is committed to providing the highest quality products to their customers, and their Honeycomb Polishing Pads are no exception. Each pad is manufactured to the highest standards, ensuring that it will provide a superior finish on any concrete surface. With their dedication to quality and innovation, it's no wonder that {Company Name} has quickly become the leading choice for contractors and DIYers when it comes to concrete polishing products.In addition to their high-quality products, {Company Name} is also known for their exceptional customer service. Their team of experts is always on hand to provide support and guidance to their customers, ensuring that they have everything they need to achieve the best possible results with their Honeycomb Polishing Pads.As the demand for high-quality concrete polishing products continues to grow, {Company Name} is poised to remain at the forefront of the industry. Their commitment to innovation, quality, and customer satisfaction is second to none, and it's clear that their Honeycomb Polishing Pads are set to revolutionize the world of concrete polishing for years to come.In conclusion, Honeycomb Polishing Pads are a game-changer for anyone looking to achieve a professional-grade finish on their concrete surfaces. With their high-gloss finish, durability, and versatility, it's no wonder that they have quickly become the go-to choice for contractors and DIYers alike. And with {Company Name} leading the way in manufacturing these innovative pads, the future of concrete polishing has never looked brighter.

High-Quality Polishing Pads for Professional Results

Polishing Pads, a key product offered by a leading polishing solutions company, have become essential tools for achieving a flawless finish in various industries, including automotive, woodworking, marine, and more. As a renowned supplier of cutting-edge polishing pads and other related products, the company has built a strong reputation for delivering high-quality and innovative solutions to its customers.With a focus on providing superior products and exceptional customer service, the company has established itself as a trusted partner for businesses looking to enhance their polishing processes. The company’s commitment to excellence is reflected in its wide range of polishing pads, which are designed to meet the diverse needs of its customers.One of the standout features of the company’s polishing pads is their durability and long-lasting performance. By utilizing advanced manufacturing techniques and high-quality materials, the company ensures that its pads provide efficient and consistent results with every use. Whether it’s for heavy-duty industrial applications or precision polishing tasks, customers can rely on the company’s pads to deliver exceptional performance.In addition to their durability, the company’s polishing pads are also designed to deliver superior polishing results. With a focus on precision and efficiency, the pads are engineered to effectively remove imperfections, smooth surfaces, and bring out a high-gloss finish. This level of quality and performance has made the company’s pads the go-to choice for professional polishers and hobbyists alike.Furthermore, the company offers a variety of polishing pads to cater to different materials and applications. From foam and wool pads for automotive polishing to specialized pads for granite and marble, the company has a comprehensive range of products to address the unique requirements of its customers. This versatility and customization options enable businesses to find the perfect polishing pad for their specific needs.The company’s dedication to innovation is also evident in its continuous efforts to develop new and improved polishing pads. By staying at the forefront of industry trends and technological advancements, the company consistently introduces cutting-edge products that push the boundaries of polishing performance. This forward-thinking approach has enabled the company to stay ahead of the competition and maintain its position as a leader in the polishing solutions market.As part of its commitment to customer satisfaction, the company also provides comprehensive support and guidance to help customers select the right polishing pads for their needs. With a team of knowledgeable and experienced professionals, the company offers valuable insights and recommendations to ensure that customers make informed decisions. Additionally, the company’s dedication to customer service extends to its after-sales support, where it provides assistance and troubleshooting to address any concerns or issues that may arise.In conclusion, Polishing Pads are a vital component of the company’s extensive range of polishing solutions. With their exceptional quality, performance, and versatility, the company’s pads have become indispensable tools for achieving impeccable finishes across various industries. By combining innovative designs with superior manufacturing standards, the company continues to set the benchmark for excellence in the polishing pads market. As businesses and professionals alike seek reliable and effective polishing solutions, the company remains a trusted partner, delivering exceptional products and unparalleled support to meet their needs.

High-Quality Granite Polishing Dry Pads Grit 0 for Effective Surface Restoration

The use of granite in interior design has been growing in popularity in recent years. Its unique pattern and durability make it a sought-after material for countertops, floors, and other surfaces. To maintain the beauty of granite surfaces, proper maintenance and care are crucial. One essential product in granite maintenance is the Granite Polishing Dry Pads Grit 0, a high-quality polishing tool that can keep granite surfaces looking their best.The Granite Polishing Dry Pads Grit 0 is a product that is making waves in the industry due to its effectiveness and efficiency. These pads are designed specifically for dry polishing, making them perfect for use on granite surfaces. The Grit 0 pads are an essential tool for removing any scratches or marks on the granite, leaving a shiny and smooth finish.One of the key features of the Granite Polishing Dry Pads Grit 0 is their durability. Made from high-quality materials, these pads are designed to withstand the rigors of granite polishing. They are long-lasting and can be used for multiple polishing sessions without losing their effectiveness. This durability makes them a cost-effective solution for granite maintenance, as they do not need to be regularly replaced.In addition to their durability, the Grit 0 pads are also known for their efficiency. They are designed to be used with minimal water, making them perfect for dry polishing. This not only saves time and effort but also reduces the mess associated with wet polishing. The pads are also easy to use, even for those who are new to granite maintenance, making them a versatile tool for both professionals and DIY enthusiasts.The company behind the Granite Polishing Dry Pads Grit 0 is a leading manufacturer in the industry, known for their commitment to quality and innovation. With years of experience in producing high-quality polishing tools, they have established themselves as a trusted name in the industry. Their products are used by professionals and homeowners alike, and their dedication to customer satisfaction has earned them a loyal following.The company takes pride in their ability to understand the needs of their customers and deliver products that exceed their expectations. The development of the Granite Polishing Dry Pads Grit 0 is a testament to their commitment to providing innovative solutions for granite maintenance. With a focus on quality and performance, the company has set a new standard for granite polishing tools.In addition to their high-quality products, the company also provides excellent customer service. Their team of experts is always available to provide support and advice on the best ways to use their products. Whether it's choosing the right tools for a specific project or troubleshooting any issues, customers can rely on the company's expertise to help them achieve the best results.The Granite Polishing Dry Pads Grit 0 is a game-changer in the world of granite maintenance. With its durability, efficiency, and ease of use, it has become a must-have tool for anyone looking to keep their granite surfaces in pristine condition. And with the backing of a reputable company known for their commitment to quality, customers can have confidence in the effectiveness of this product.In conclusion, the Granite Polishing Dry Pads Grit 0 is a product that has revolutionized granite maintenance. With its high-quality materials, durability, and efficiency, it has set a new standard for polishing tools. Combined with the company's dedication to customer satisfaction, it is clear that this product is a top choice for anyone looking to maintain the beauty of their granite surfaces.

Enhance Your Concrete Floors with Premium Sanding Pads for Flawless Finish

Concrete Floor Sanding Pads: A Revolutionary Solution for the Flooring IndustryFlooring has always been an essential part of the construction industry. From residential to commercial spaces, flooring plays a crucial role in creating a safe and comfortable environment. However, with time and usage, floors can become dull and damaged, requiring a repair or replacement. This is where sanding comes in.Sanding is one of the most popular methods of floor restoration. It involves using abrasive materials to remove the top layer of the floor, revealing a fresh and smooth surface underneath. However, the process of sanding can be time-consuming and tedious, especially when dealing with concrete floors.Enter the Concrete Floor Sanding Pads. These innovative tools have proven to be a game-changer in the flooring industry. Designed to work with various types of sanding machines, Concrete Floor Sanding Pads offer an efficient and cost-effective solution to sanding concrete floors.The Concrete Floor Sanding Pads are made from high-quality materials and feature a diamond abrasive coating. This coating allows for a more aggressive sanding action, resulting in faster material removal and a smoother finish. The pads are also designed to be used dry, eliminating the need for water or messy lubricants.One of the unique features of the Concrete Floor Sanding Pads is their ability to effectively sand uneven surfaces. Traditional sanding methods often struggle to reach the crevices and corners of rough concrete floors, resulting in an uneven finish. The diamond coating on the Concrete Floor Sanding Pads allows for a more precise sanding action, making it possible to achieve a uniform finish on even the most uneven surfaces.The Concrete Floor Sanding Pads are also designed to last longer than traditional sanding discs or belts. The diamond coating on the pads is highly durable, allowing them to withstand the rigors of heavy usage. This durability translates into cost savings for flooring contractors, as they will not have to replace the pads as often as other sanding materials.At [company name], we are proud to offer a range of Concrete Floor Sanding Pads designed to meet the needs of flooring contractors and DIY enthusiasts alike. Our pads are available in various grit sizes, making it easy to achieve the desired finish on any concrete floor. Additionally, we offer bulk pricing and custom sizes, ensuring that our pads are accessible to everyone in the industry.Overall, Concrete Floor Sanding Pads are a game-changer in the flooring industry. They offer a fast, efficient, and cost-effective solution to sanding concrete floors, making them an essential tool for contractors and DIY enthusiasts alike. At [company name], we are committed to providing high-quality sanding pads and excellent customer service to help our clients achieve their flooring goals.

Top 7 Inch Grinding Wheel: Essential Tool for Precision and Efficiency

Title: High-Quality 7-Inch Grinding Wheel Now Available for Enhanced Precision and EfficiencyIntroduction:In a recent development, a renowned company, specializing in industrial tools and machinery, has released its latest offering - a top-notch 7-inch grinding wheel. Designed to deliver superior performance, this all-new grinding wheel promises enhanced precision and efficiency. The company, known for its commitment to quality and innovation, has once again raised the bar in the field of industrial abrasives.[Company Name - OPTIONAL]:With over [number of years] of experience, and a strong presence in the industrial sector, this company has become a trusted name for professionals and hobbyists alike. Established with the goal of providing cutting-edge tools and machinery, the company has consistently delivered products that exceed the expectations of its customers. Renowned for its commitment to quality, reliability, and customer satisfaction, the company continues to be a prominent player in the industry.The 7-Inch Grinding Wheel:The newly launched 7-inch grinding wheel is the result of extensive research and development efforts by the company's team of experts. Crafted with precision, the wheel offers exceptional durability and performance, making it an ideal choice for various grinding applications. Equipped with advanced features, this grinding wheel ensures an efficient workflow while adding a touch of convenience to the user's experience.The key features of the 7-inch grinding wheel include:1. High-Quality Materials: Crafted from premium-grade materials, this grinding wheel offers excellent durability and long-lasting performance, even under challenging working conditions. Its construction guarantees minimal wear and tear, ensuring a prolonged product lifespan.2. Precise Grinding: The 7-inch wheel has been engineered to deliver precise grinding and smoothing results. Its balanced design ensures smooth operation and reduced vibrations, allowing for consistent and accurate material removal. This feature enables users to achieve desired finishes promptly and efficiently.3. Versatility: The grinding wheel is compatible with various materials, including metal, stone, ceramics, and more. Its versatility enables users to tackle a wide range of applications, making it an indispensable tool in industries such as construction, automotive, and manufacturing.4. Easy Installation: Designed with user convenience in mind, this grinding wheel features a hassle-free installation process. Equipped with a universal spindle size, it can be quickly mounted on most grinders, reducing downtime and improving productivity.5. Enhanced Safety: Prioritizing user safety, the grinding wheel incorporates features such as reinforced construction and adequate heat dissipation. These safety measures minimize the risk of accidents, ensuring a secure working environment.6. Performance Efficiency: The 7-inch size of the wheel allows for greater surface coverage, resulting in improved efficiency and time-saving benefits. The wheel's optimal composition guarantees smooth and consistent grinding, reducing the need for frequent tool changes.Conclusion:The introduction of the high-quality 7-inch grinding wheel has made a significant impact on professionals and hobbyists in various industries. With its durable construction, precise grinding capabilities, and enhanced safety features, this tool is set to elevate the standards of grinding efficiency, while maintaining the company's reputation for producing reliable and innovative products.As the company continues to pave the way in the field of industrial tools and machinery, the 7-inch grinding wheel stands out as a testament to their commitment to delivering superior performance and meeting the evolving needs of their customers.

The Difference Between Metal Bonds and Nonmetals Explained

Metal Bonds and Nonmetal, a leading global company in the field of industrial materials, recently announced a breakthrough in the development of a new type of metal bond and nonmetal technology. The company has been a pioneer in the industry for over two decades and has continuously strived to push the boundaries of innovation and advancement in industrial materials.With a strong focus on research and development, Metal Bonds and Nonmetal has been able to stay at the forefront of the industry. The company's team of experts has been working tirelessly to develop new and advanced materials that can meet the evolving needs of various industries. This dedication to innovation has now resulted in the development of a groundbreaking metal bond and nonmetal technology that is set to revolutionize the market.The new technology developed by Metal Bonds and Nonmetal offers a unique combination of metal bonds and nonmetal materials, creating a highly versatile and durable material that can be used across a wide range of applications. This innovative approach to material development has the potential to significantly impact industries such as automotive, aerospace, construction, and more.The new metal bond and nonmetal technology has been proven to exhibit superior strength, durability, and resistance to wear and tear. This makes it an ideal choice for applications that require high-performance materials, such as cutting tools, grinding wheels, and industrial machinery. The technology's versatility also makes it suitable for a wide range of other applications, providing a cost-effective and sustainable solution for various industries.Metal Bonds and Nonmetal's new technology is expected to disrupt the market by offering a unique alternative to conventional materials. With its superior performance and adaptability, the new metal bond and nonmetal technology has the potential to replace traditional materials in many applications, offering significant cost savings and environmental benefits.The company's commitment to sustainability and environmental responsibility is evident in the development of this new technology. By creating a material that is highly durable and long-lasting, Metal Bonds and Nonmetal is contributing to the reduction of waste and the promotion of a more sustainable industrial landscape.Furthermore, the new technology also has the potential to significantly improve the efficiency and productivity of various industries. Its exceptional durability and resistance to wear and tear make it an ideal choice for high-stress applications, allowing for longer tool life and reduced downtime for machinery and equipment.Metal Bonds and Nonmetal has already begun working with industry partners to bring this revolutionary technology to market. The company is confident that the new material will gain rapid acceptance and adoption across various sectors, positioning it as a leader in the advancement of industrial materials.Overall, Metal Bonds and Nonmetal's new metal bond and nonmetal technology represents a significant milestone in the company's journey of innovation and advancement. With its unique combination of strength, durability, and versatility, the new technology has the potential to transform the industrial materials market and bring about positive change for industries around the world. As a company that has consistently demonstrated its dedication to pushing the boundaries of innovation, Metal Bonds and Nonmetal is set to continue leading the way in the development of high-performance and sustainable materials for industrial applications.

High-Quality Buffer Polisher Pads for a professional shine

Buffing and polishing are essential processes in the automotive and industrial sectors, and having the right tools is crucial for achieving high-quality results. Buffer polisher pads are key components in this process, providing the necessary surface for achieving a smooth and polished finish. One company that has been making a name for itself in this industry is {company name}, a leading manufacturer of a wide range of buffer polisher pads.{Company name} has been in the business for over two decades, and their dedication to quality and innovation has made them a trusted name in the industry. They offer a variety of buffer polisher pads to suit different applications, including foam pads, wool pads, and microfiber pads. Their pads are designed to deliver excellent results, whether it's for removing scratches, achieving a high-gloss finish, or simply maintaining the shine of a surface.What sets {company name} apart from other manufacturers is their commitment to using high-quality materials and advanced manufacturing processes. Their buffer polisher pads are made from premium foam and fibers that are designed to withstand the rigors of buffing and polishing. This ensures that the pads are not only durable but also provide consistent performance over time.Another important aspect of {company name}'s buffer polisher pads is their versatility. They offer pads in different sizes and densities to cater to the varying needs of their customers. Whether it's for a small-scale detail job or a large industrial application, {company name} has the right buffer polisher pad for the job.In addition to their standard range of buffer polisher pads, {company name} also offers custom solutions for customers with specific requirements. Their team of experienced engineers and technicians work closely with clients to develop tailor-made pads that meet their exact specifications. This level of customization has helped {company name} build long-lasting relationships with their customers, who trust them to deliver pads that exceed their expectations.To ensure the quality of their buffer polisher pads, {company name} has implemented strict quality control measures throughout the manufacturing process. From the selection of raw materials to the final inspection of finished products, every step is closely monitored to ensure that only the best pads reach the market. This commitment to quality has helped {company name} earn ISO certification, further solidifying their reputation as a reliable and trustworthy manufacturer.As part of their efforts to stay ahead of the competition, {company name} continually invests in research and development. Their team is always exploring new materials and manufacturing techniques to improve the performance and durability of their buffer polisher pads. This commitment to innovation has led to the introduction of cutting-edge products that have set new standards in the industry.One example of {company name}'s innovative approach is their focus on eco-friendly buffer polisher pads. With increasing awareness of environmental issues, {company name} has developed a range of pads that are made from sustainable materials and are designed to minimize waste during the manufacturing process. This eco-friendly range has been well-received by customers who are looking to reduce their environmental footprint without compromising on performance.In conclusion, {company name} has established itself as a leading manufacturer of buffer polisher pads, thanks to their unwavering commitment to quality, innovation, and customer satisfaction. With a diverse range of products, a dedication to customization, and a focus on sustainability, {company name} is well-positioned to continue meeting the needs of their customers and shaping the future of buffing and polishing technology.

Learn about the benefits of a wood floor sanding edging machine

Wood Floor Sanding Edging Machine: A Breakthrough in Flooring TechnologyWooden floors add a touch of elegance and warmth to any space, but maintaining their beauty requires regular maintenance and refinishing. This is where the innovative Wood Floor Sanding Edging Machine, developed by the leading flooring equipment manufacturer, comes into play.With a rich history spanning over three decades, our company has been at the forefront of developing cutting-edge solutions for the flooring industry. Our commitment to excellence and innovation has allowed us to establish ourselves as a trusted and reliable partner for professionals in the field.The Wood Floor Sanding Edging Machine is the latest addition to our extensive range of flooring equipment, and it promises to revolutionize the way wooden floors are refinished. This state-of-the-art machine is designed to efficiently sand and refinish the edges of wooden floors, giving them a seamless and professional look.One of the key features of the Wood Floor Sanding Edging Machine is its powerful motor, which ensures that the sanding process is quick and effective. This not only saves time for the professionals using the machine but also ensures that the final result is of the highest quality.Moreover, the machine is equipped with a dust collection system, which not only keeps the work area clean and free from dust but also contributes to a healthier and safer working environment for the operators.Another standout feature of the Wood Floor Sanding Edging Machine is its ergonomic design, which makes it easy to handle and operate. This means that professionals can work for longer periods without feeling fatigued, resulting in higher productivity and better results.In addition to its practical features, the Wood Floor Sanding Edging Machine is also built to last. The robust construction and high-quality materials used in its manufacturing ensure that it can withstand the rigors of daily use, making it a reliable and long-lasting investment for flooring professionals.The Wood Floor Sanding Edging Machine is also backed by our company's excellent customer support and after-sales service. Our team of experts is always on hand to provide assistance and guidance, ensuring that our customers get the most out of their investment in our products.The launch of the Wood Floor Sanding Edging Machine has already created a buzz in the industry, with professionals praising its performance and reliability. Many have expressed their excitement about the prospect of using this innovative machine to elevate the quality of their work and streamline their operations."I have been using the Wood Floor Sanding Edging Machine for the past month, and it has completely transformed the way I work. The efficiency and precision it offers are unparalleled, and I can't imagine going back to my old methods," said a satisfied customer.With the Wood Floor Sanding Edging Machine, our company continues to push the boundaries of innovation in the flooring industry. We are proud to offer professionals a reliable and cutting-edge solution that not only improves the quality of their work but also enhances their overall work experience.As we look to the future, our commitment to excellence remains unwavering, and we are excited about the prospect of continuing to develop innovative solutions that empower professionals in the flooring industry. The Wood Floor Sanding Edging Machine is just the beginning of what promises to be an exciting journey of innovation and progress for our company and our customers.