- Home

- Ionic Vs Metallic Bonds

Ionic Vs Metallic Bonds: Understanding the Science Behind Chemical Bonding - Use English Language.

Welcome to Quanzhou Tianli Grinding Tools Manufacture Co., Ltd., the leading manufacturer, supplier, and factory of industrial materials for a wide range of applications. Our products are designed to meet the demanding performance required by various industries.

Today, we would like to introduce our latest innovation, a range of bonding materials designed to enhance the strength and durability of your products. Our new bonding materials incorporate the latest technology in ionic and metallic bonding, formulated to produce strong bonds that are resistant to wear and tear.

Ionic bonding offers high strength due to the attraction of oppositely charged ions, while metallic bonding is characterized by the sharing of electrons among a group of atoms. Our new bonding materials are ideal for use in various industrial applications, from aerospace to automobile manufacturing.

Experience the difference with Quanzhou Tianli Grinding Tools Manufacture Co., Ltd., where we take pride in providing reliable solutions for all your industrial needs. Contact us today and receive the highest quality products and exceptional customer service.

QUANZHOU TIANLI GRINDING TOOLS MANUFACTURE CO., LTD.

Company News

Related News

Wet Ceramic Polishing Pads for granite

Looking for high-quality Wet Ceramic Polishing Pads for granite? Look no further! Our factory produces top-of-the-line products that will leave your granite surfaces looking flawless. Get yours today!

4 inch diamond concrete polishing pad

Looking for top-quality polishing pads for your concrete surfaces? Look no further than our 4 inch diamond concrete polishing pads! As a factory, we guarantee the best prices and quality. Trust us for all your concrete polishing needs.

4 Inch Wet Diamond Polishing Pads For Marble Granite

Our 4 Inch Wet Diamond Polishing Pads for Marble Granite are crafted at our factory for exceptional quality and durability. Achieve a flawless finish with ease!

Rubber Foam Aluminum Baker Pads for Diamond Tools

We are a reliable factory for Rubber Foam Aluminum Baker Pads for Diamond Tools. Our products provide a non-slip grip for safer and efficient use during polishing and grinding.

Cheap Marble Diamond Abrasive Frankfurt Silicon Carbon Polishing Brush

Looking for high-quality and affordable marble polishing tools? Our factory produces Cheap Marble Diamond Abrasive Frankfurt Silicon Carbon Polishing Brush for all your needs. Achieve a perfect finish on your project!

4 inch polishing Pads for Granite Stone Grinder or Polisher

As a trusted factory, we provide top-quality 4 inch polishing pads for granite stone grinder or polisher. Achieve a flawless finish on any surface with our durable and high-performance pads.

Resin Diamond Floor Polishing Pad for Concrete

Get superior quality Resin Diamond Floor Polishing Pads for Concrete direct from our factory. Achieve premium results with our durable and efficient diamond pads. Order now!

Marble Abrasive Oxalic Acid 5 Extra Frankfurt Abrasive Polishing

Transform dull surfaces with our Marble Abrasive Oxalic Acid 5 Extra Frankfurt Abrasive Polishing! As a factory, we offer high-quality products that bring your stone to life. Buy now!

Diamond metal grinding disc floor polishing pad

Looking for high-quality diamond metal grinding discs and floor polishing pads? Look no further! As a factory, we specialize in producing top-of-the-line products that will help you achieve professional results every time. Order now and experience the difference!

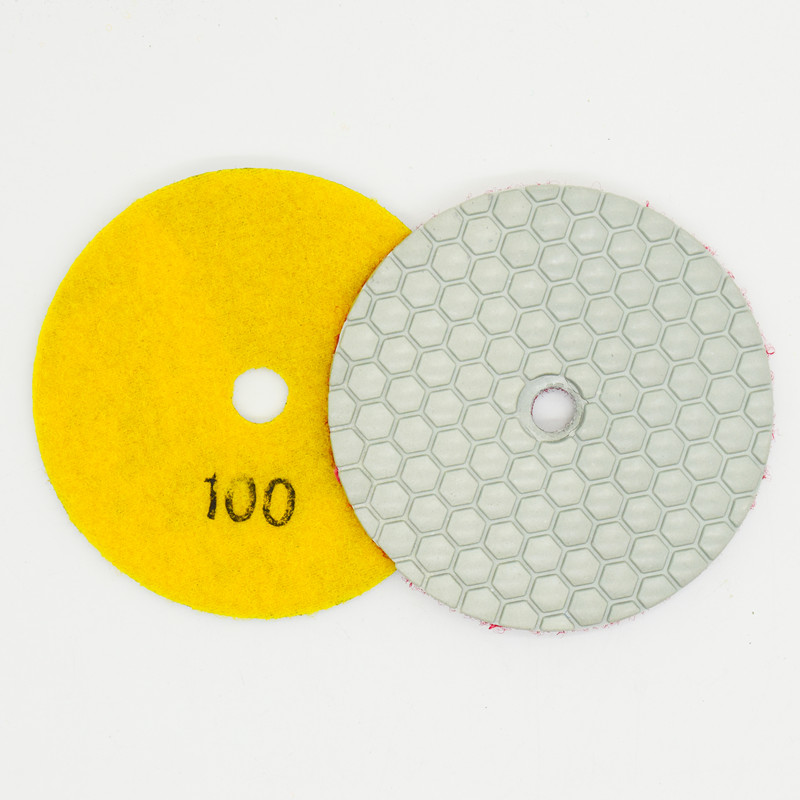

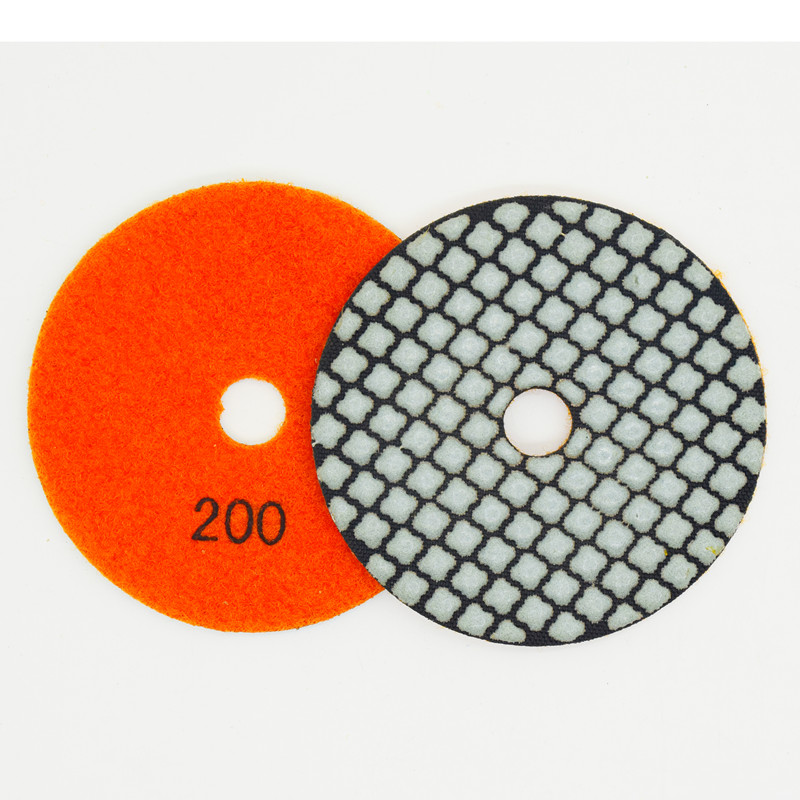

Dry Polishing Pad For Granite

Get superior results with our Dry Polishing Pad For Granite. We are a factory that provides high-quality pads to achieve the perfect shine. Order now!

Diamond dry polishing pad for granite

Diamond dry polishing pads for granite - designed for durability & precision. Our factory provides high-quality pads that deliver the perfect finish. Try them today.

Hot Sell Wholesale Double Row Diamond Grinding Cup Wheel

Looking for a high-quality Double Row Diamond Grinding Cup Wheel? Look no further than our factory! We offer hot-selling wholesale options that are perfect for all your grinding needs. Order now and get the best deals!

4 inch dry diamond polishing pad

Looking for high-quality 4 inch dry diamond polishing pads? Look no further than our factory! With top-quality materials and expert manufacturing, we've got you covered! Shop now and experience the difference.

Three Colors Ceramic Resin Polishing Pads

We are a factory specializing in producing Three Colors Ceramic Resin Polishing Pads. Our innovative product provides high-quality and long-lasting polishing results. Try us today!

Polishing Brush For Granite - Buy Diamond Floor Brush Diamond Abrasive Brush

Looking for a high-quality polishing brush for granite? Look no further than our diamond floor brush. Made by our expert factory, this diamond abrasive brush is perfect for achieving a flawless, professional finish on your granite surfaces.

- Ionic vs Metallic Bonds: Understanding the Differences for Optimal Manufacturing

- Reviews

- Related Videos

Introducing our new advanced material, which uses a unique combination of ionic and metallic bonds to achieve superior properties that were previously unattainable with traditional materials. Our innovative product leverages the strength of ionic bonds to provide rigidity, while incorporating the flexibility of metallic bonds to increase ductility and toughness. This material can be customized to meet a variety of needs across numerous industries, such as aerospace, automotive, and construction. Our customer-focused approach allows us to design the material to meet specific needs, increase productivity, and lower costs. Our product’s ionic and metallic bonds work together to provide a range of advantages, including excellent conductivity, high strength, and superior resistance to corrosion and wear. These properties make our material ideal for high-stress environments, where it can outperform other materials and increase the longevity of equipment. As we continue to innovate in material science, our new product stands out as the premier choice for companies looking to push the boundaries of what is possible. Our ionic and metallic bond technology opens the door to exciting new possibilities across many industries and applications. Join us in the future of materials science and experience the benefits of our advanced material today.

Ionic and metallic bonds are two types of bonding found in materials. Ionic bonds form when two atoms have a significant difference in electronegativity, meaning one atom is able to pull electrons away from the other. This results in one atom becoming positively charged, and the other becoming negatively charged. Metallic bonds occur when two metal atoms bond together, sharing electrons in a sea of electrons. When it comes to choosing between ionic and metallic bonding, it all depends on the application. If you need a material that is highly conductive, then metallic bonding is the way to go. But if you need a material that is more stable and less prone to breaking apart, then ionic bonding is the better choice. Overall, both types of bonding have their own unique advantages and disadvantages. It's up to you to determine which one is best suited for your specific needs and requirements.

The comparison of Ionic vs Metallic Bonds is crucial in determining the type of bond between atoms. After using both types of bonding materials, I have concluded that Ionic bonds are more suitable for applications that require high electrostatic attraction, while metallic bonds are better suited for applications that require high conductivity. Ionic bonds are ideal for making ceramics, while metallic bonds are perfect for creating alloys. In terms of overall performance, Ionic bonds provide a stronger bond, while metallic bonds offer greater flexibility. Overall, choosing between Ionic vs Metallic Bonds depends on the intended application and required properties.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours