Top Abrasive Manufacturers: A Comprehensive Guide to Choosing the Right Supplier

By:Admin

Established over [number] years ago, the company has grown to become a key player in the abrasive manufacturing sector, serving clients in various industries including automotive, aerospace, metal fabrication, and construction. The company's extensive product line includes a diverse range of abrasive materials such as bonded abrasives, coated abrasives, and superabrasives, all of which are designed to deliver exceptional results in precision grinding, cutting, and surface finishing.

One of the company's core strengths lies in its relentless pursuit of innovation. Through ongoing research and development efforts, the company continues to introduce cutting-edge abrasive solutions that offer enhanced performance, durability, and cost-effectiveness. By leveraging advanced manufacturing technologies and materials, the company has been able to stay ahead of the curve in meeting the evolving needs of its customers.

In addition to its focus on product innovation, the company places a strong emphasis on quality control and assurance. This commitment to excellence is evident in the company's state-of-the-art manufacturing facilities and rigorous quality testing processes, which ensure that each batch of abrasives meets the highest standards of consistency and performance.

Furthermore, the company's dedication to customer satisfaction is reflected in its comprehensive technical support and customized solutions. With a team of experienced engineers and technical experts, the company is able to provide valuable assistance to clients in choosing the right abrasive products for their specific applications. Whether it's optimizing cutting parameters, troubleshooting surface finishing issues, or recommending the most suitable abrasives for a particular material, the company's technical support team is always ready to offer expert guidance and assistance.

Another key aspect of the company's success is its commitment to sustainability and environmental responsibility. In an industry where waste and environmental impact are of growing concern, the company has taken proactive measures to minimize its carbon footprint and reduce waste generation. From utilizing eco-friendly manufacturing processes to promoting the use of recyclable materials, the company is dedicated to operating in an environmentally sustainable manner.

Beyond its commitment to excellence, innovation, and sustainability, the company also prides itself on its strong corporate values and ethical business practices. With a focus on integrity, transparency, and fair business dealings, the company has earned a solid reputation for reliability and trustworthiness in the industry.

Looking ahead, the company remains steadfast in its commitment to pushing the boundaries of abrasive technology and delivering superior solutions to its customers. With a strong focus on continuous improvement and a customer-centric approach, the company is well-positioned to maintain its leadership in the abrasive manufacturing sector and drive further growth and success in the years to come.

Company News & Blog

Enhance Your Vehicle's Shine with 7 Inch Buffing and Polishing Pads

The importance of maintaining a clean and polished vehicle cannot be overstated. Not only does it enhance the overall look of the car, but it also ensures that its value is preserved. This is where 7 Inch Buffing and Polishing Pads come in. These pads are the perfect tool for vehicle detailing and provide a quick and easy way to restore that showroom shine to any car.In recent news, a well-known auto detailing company has launched a new range of 7 Inch Buffing and Polishing Pads designed to help customers achieve a high-quality, professional finish. The company, which specializes in car care products, offers a wide range of services and products for both interior and exterior car care. This new range of Buffing and Polishing Pads is just one example of the innovative and effective products that they provide to car enthusiasts around the world.The 7 Inch Buffing and Polishing Pads are made from high-quality materials that ensure long-lasting durability. They come in a variety of different colors, each with a specific purpose. The orange pad, for example, is designed for aggressive cutting and is perfect for removing heavy oxidation and scratches. The green pads, on the other hand, are the perfect choice for removing moderate scratches and swirl marks. The company's unique white pad is perfect for light oxidation removal, while the black pad is designed for finishing and final buffing.In addition to their high-quality materials and variety of uses, the 7 Inch Buffing and Polishing Pads are easy to use and versatile. They can be used with both electric and air-powered polishing machines. The pads are also easy to attach and detach without the need for any special tools. This makes them an ideal choice for anyone looking to achieve a professional finish on their car from the comfort of their own garage.One of the key benefits of the 7 Inch Buffing and Polishing Pads is that they are ideal for a wide range of vehicle types. Whether you have a sports car, SUV, or classic car, these pads can help to restore the shine and make your vehicle look like new again. They are also perfect for boat owners who want to keep their vessels looking their best, as well as owners of motorcycles, ATVs, and other motorized vehicles.The company offering these Buffing and Polishing Pads have a strong reputation in the automotive industry. With years of experience in the field of car care and detailing, they know what customers need and have worked hard to provide it. Their range of products includes everything from car wax and polishes to car wash soaps and brushes.The launch of their new range of 7 Inch Buffing and Polishing Pads is just one example of their commitment to innovation and customer satisfaction. With each new product release, they aim to make the car care process easier and more effective for their customers.In conclusion, the 7 Inch Buffing and Polishing Pads are a must-have for any car enthusiast looking to achieve a high-quality, professional finish on their vehicle. With their superior materials and variety of uses, they are a versatile tool that can help to restore the shine and beauty of any car, boat, or motorcycle. The Launch of this new range of buffing and polishing pads demonstrates the commitment of this reputed company to continue providing the best products to their customers.

Ceramic Grinding Discs: Latest News and Insights to Optimize Your Grinding Efficiency

Title: Revolutionary Ceramic Grinding Disc Revolutionizes Material FinishingIntroduction:In today's rapidly evolving industrial world, the demand for high-quality surface finishes has become paramount. Companies across various sectors are continuously seeking innovative solutions to achieve efficient and precise material finishing to meet the growing consumer demands. This has led to the development of a breakthrough product in the form of the Ceramic Grinding Disc. This news article will delve into the benefits and applications of this remarkable tool, exploring the company {company name} behind its creation and outlining its potential to revolutionize material finishing.I. Readying the Stage for Revolutionary Grinding Techniques (150 words)With traditional grinding tools competing to deliver the highest level of precision, the Ceramic Grinding Disc emerges as a game-changer in the industry. Developed by {company name}, a renowned manufacturer of cutting-edge abrasive products, this disc offers unmatched performance, durability, and quality.II. Unveiling the Ceramic Grinding Disc's Cutting-Edge Technology (150 words)The Ceramic Grinding Disc stands out due to its utilization of advanced materials and manufacturing techniques. Made from high-quality ceramic particles, the disc exhibits exceptional hardness, enabling it to maintain its sharpness and provide consistent performance throughout its use. Its superior heat and wear resistance make it suitable for a wide range of applications, including metal, stainless steel, and even exotic alloy material finishes.III. The Unparalleled Advantages of the Ceramic Grinding Disc (200 words)Thanks to its unique attributes, the Ceramic Grinding Disc offers several advantages over traditional abrasive tools. Firstly, its durability ensures a longer lifespan, reducing the frequency of tool replacements and lowering overall production costs. Additionally, its sharp cutting capabilities significantly enhance material removal rates, leading to improved efficiency and productivity. Moreover, the disc's exceptional heat resistance prevents overheating during demanding applications, resulting in reduced workpiece damage and improved machine operator safety. IV. Applications and Industries Benefitting from the Ceramic Grinding Disc (150 words)The versatility of the Ceramic Grinding Disc allows it to find applications in a multitude of industries. In the metalworking sector, manufacturers can achieve flawless surface finishes on steel, aluminum, and cast iron components. In the automotive industry, this cutting-edge tool can be employed for precision grinding of engine parts, brakes, and transmissions. Moreover, the disc finds use in the aerospace sector for deburring, grinding, and surface preparation of intricate components. The construction and woodworking sectors also benefit from the disc's versatility in shaping and smoothing a wide array of materials.V. The Visionary Masterminds behind the Ceramic Grinding Disc (150 words){Company name}, the pioneering force behind the Ceramic Grinding Disc, has a long-standing reputation for developing innovative abrasive solutions. Committed to pushing the boundaries of what's possible, the company invests heavily in research and development. Their expertise, combined with a deep understanding of the industry's challenges, has culminated in the creation of this extraordinary tool. With a track record of delivering premium products and an unwavering commitment to customer satisfaction, {company name} aims to transform the way manufacturers approach material finishing.Conclusion:As the demand for impeccable material finishes continues to grow, the Ceramic Grinding Disc emerges as a revolutionary solution. Offering unrivaled performance, durability, and versatility across multiple industries, this cutting-edge tool represents a paradigm shift in material finishing. In collaboration with {company name}, manufacturers can now achieve exceptional results while increasing productivity, reducing costs, and improving safety.

Angle Grinder Polishing Pad: A Comprehensive Guide to Achieving a Perfect Polish

Title: Advanced Angle Grinder Polishing Pad Revolutionizes Surface Polishing TechniquesIntroductionIn the ever-evolving world of surface polishing, a new contender has emerged to transform the way professionals approach their craft. The latest innovation, the Angle Grinder Polishing Pad, developed by an industry-leading company (brand name removed), sets a new standard for efficiency, precision, and versatility. This breakthrough product empowers professionals in various fields, from automotive and construction to woodworking and metalworking, to achieve impeccable finishes and uncompromised performance. With its exceptional features, the Angle Grinder Polishing Pad is poised to redefine the industry's approach to surface polishing.1. Unparalleled Efficiency and PerformanceThe Angle Grinder Polishing Pad boasts a revolutionary design that prioritizes efficiency without compromising on performance. Equipped with advanced abrasive technology, this pad significantly reduces polishing time, delivering remarkable results in half the time compared to conventional polishing products. Its strategic composition allows for increased heat dissipation during use, preventing overheating and extending the lifespan of the pad itself. This unparalleled efficiency not only maximizes productivity but also reduces operational costs for professionals across the board.2. Versatility for Multiple ApplicationsDesigned with versatility in mind, the Angle Grinder Polishing Pad caters to various industries and applications. Whether polishing metal surfaces, woodwork, or automotive paint, this pad proves to be an indispensable tool. The unique composition ensures compatibility with a wide range of materials without compromising performance. Professionals no longer need to acquire multiple pads, reducing costs and simplifying their work. This all-in-one solution empowers individuals to tackle diverse surfaces with ease, expanding their capabilities and amplifying the value they provide to their clients.3. Enhanced Safety FeaturesThe Angle Grinder Polishing Pad places immense importance on user safety. The company has integrated cutting-edge safety features that mitigate the risk of accidents and injuries during operation. The pad's ergonomic design promotes comfortable handling, reducing strain and fatigue, even during prolonged use. Furthermore, special attention has been given to reducing vibrations and controlling noise levels, ensuring a safer working environment for professionals and decreasing the risk of long-term health issues related to excessive vibration exposure.4. Environmental SustainabilityIn recognition of pressing environmental concerns, the Angle Grinder Polishing Pad sets an industry benchmark for sustainability. Constructed from eco-friendly materials, this pad aligns with the company's commitment to reducing its ecological footprint. Additionally, its extended lifespan maximizes the pad's durability, further minimizing waste generation. As professionals adopt this environmentally conscious product, they contribute to a greener planet while achieving exceptional polishing outcomes.ConclusionThrough relentless innovation and dedication to meeting industry demands, the Angle Grinder Polishing Pad has emerged as a game-changer in the field of surface polishing. Delivering exceptional efficiency, unmatched versatility, and enhanced safety features, this revolutionary product empowers professionals to surpass their clients' expectations. With a commitment to environmental sustainability, the Angle Grinder Polishing Pad paves the way for a more eco-conscious approach to surface polishing. As the industry embraces this cutting-edge technology, the standards in surface polishing are set to reach new heights.

Unlock Brilliance with Innovative Diamond Polishing Pads

Title: Revolutionary Diamond Polishing Pad Promises Unmatched Precision in Surface FinishingIntroduction:Innovative advancements in the field of construction materials continue to revolutionize traditional techniques and contribute to more efficient and precise results. Recently, a renowned company has introduced the revolutionary Snail Lock Edge Diamond Polishing Pad, which promises to redefine surface finishing in various industries. This cutting-edge product boasts unparalleled performance and precision, making it a game-changer for professionals seeking pristine surface quality.I. Snail Lock Edge Diamond Polishing Pad: Unmatched Quality and PerformanceThe Snail Lock Edge Diamond Polishing Pad is manufactured with the highest-grade synthetic diamonds embedded in a flexible resin bond matrix. This combination ensures enhanced durability and optimal polish retention, making it ideal for extensive surface refinement tasks. Unlike conventional polishing pads, its innovative snail lock edge design offers seamless attachment for a hassle-free and secure connection to compatible polishing machinery.II. Superior Features and Benefits1. Advanced Diamond Technology:With state-of-the-art diamond technology, the Snail Lock Edge Diamond Polishing Pad guarantees exceptional cutting power and increased polishing efficiency. The synthetic diamonds used in its composition offer superior hardness, making it suitable for a wide range of surfaces, including marble, granite, quartz, and floor tiles.2. Enhanced Durability and Longevity:The resin bond matrix ensures the diamond particles adhere firmly to the pad's surface, preventing premature wear. This feature promotes extended tool life, making it a cost-effective option for professionals in the construction and renovation industries.3. Superior Precision:The combination of the high-quality diamond particles and flexible resin bond matrix allows for precise polishing and finishing on various materials. Professionals can achieve a flawless mirror finish through a multi-step polishing process, ensuring superior aesthetics in their projects.III. Application Areas:1. Construction Industry:The Snail Lock Edge Diamond Polishing Pad finds extensive use in the construction industry, particularly in the final stages of surface finishing. It assists in achieving an impeccable finish on countertops, stairs, and flooring, enhancing the overall appeal of residential and commercial spaces.2. Renovation and Restoration:Professionals involved in renovation and restoration projects can rely on this diamond polishing pad to breathe new life into worn-out surfaces. Whether it's reviving faded marble or refinishing historical structures, the pad's exceptional polish retention and cutting power ensure optimal results.3. Automotive and Aerospace:Even industries like automotive and aerospace benefit from the precision and versatility of the Snail Lock Edge Diamond Polishing Pad. Its ability to work on various materials such as plastic, glass, and metal enables professionals to achieve impeccable finishes on interior and exterior component surfaces.IV. Commitment to Sustainability:The company behind the Snail Lock Edge Diamond Polishing Pad is committed to sustainability. The manufacturing process adheres to strict environmental standards, minimizing waste generation and reducing the carbon footprint. Additionally, the pad's long lifespan reduces overall material consumption, promoting sustainable practices within the industry.V. Conclusion:The introduction of the Snail Lock Edge Diamond Polishing Pad presents a groundbreaking solution for professionals in various industries seeking unmatched precision and quality in surface finishing. Its cutting-edge diamond technology, durability, and versatility make it a valuable tool for achieving flawless results. As this revolutionary product continues to garner attention, it undoubtedly heralds a new era in the field of construction materials, offering professionals a means to elevate their craftsmanship to new heights.

Highly Effective Flap Brush Wheel for Various Applications

Flap Brush Wheel: A Versatile Tool for Surface FinishingSurface finishing is an essential aspect of many industries, from manufacturing and construction to automotive and aerospace. The quality of surface finishing can significantly impact the performance and durability of a product, making it crucial for businesses to invest in high-quality tools and equipment for this purpose. One such tool that has gained popularity in the industry is the flap brush wheel, a versatile and efficient tool for achieving various surface finishes.A flap brush wheel, also known as a flap wheel or flap brush, is a type of abrasive tool that is used for blending, deburring, and polishing a wide range of materials, including metal, wood, and plastic. It consists of a series of abrasive flaps attached to a central hub, which is then mounted on a power tool for use. The flaps are made from various abrasive materials such as aluminum oxide, silicon carbide, and zirconia alumina, which gives the flap brush wheel its cutting and grinding capabilities.One of the leading manufacturers of flap brush wheels is {Company Name}. With over 20 years of experience in the industry, {Company Name} has established itself as a trusted supplier of abrasive tools and equipment for surface finishing. The company prides itself on its commitment to quality, innovation, and customer satisfaction, which has earned it a loyal customer base and a reputation for excellence in the industry.{Company Name} offers a wide range of flap brush wheels designed to meet the diverse needs of its customers. From small, hand-held flap wheels for precision finishing to large, industrial-grade flap wheels for heavy-duty applications, the company's product line caters to various industries and applications. Its flap brush wheels are available in different abrasive materials, grit sizes, and configurations, allowing customers to achieve the desired surface finish with ease.In addition to its standard product offerings, {Company Name} also specializes in custom flap brush wheels tailored to specific customer requirements. The company's team of experienced engineers and technicians work closely with customers to understand their needs and develop custom solutions that meet their exact specifications. This personalized approach sets {Company Name} apart from its competitors and has made it a preferred supplier for many businesses in the industry.One of the key advantages of using flap brush wheels from {Company Name} is their superior performance and durability. The company utilizes advanced manufacturing processes and quality control measures to ensure that its flap brush wheels meet the highest standards of quality and consistency. As a result, customers can rely on {Company Name}'s products to deliver exceptional results consistently, leading to improved productivity and cost savings in their surface finishing operations.Furthermore, {Company Name} is committed to sustainability and environmental responsibility in its manufacturing processes. The company invests in eco-friendly technologies and materials to minimize its environmental impact and reduce waste generation. Customers who choose {Company Name} as their supplier for flap brush wheels can be assured that they are supporting a company that prioritizes environmental stewardship and corporate social responsibility.As the demand for high-quality surface finishing continues to grow across various industries, the importance of using reliable and efficient tools such as flap brush wheels cannot be overstated. With its extensive experience, commitment to quality, and dedication to customer satisfaction, {Company Name} is well-positioned to meet the evolving needs of its customers and remain a leading provider of flap brush wheels in the industry.In conclusion, flap brush wheels are a versatile and essential tool for achieving superior surface finishes, and {Company Name} is a trusted and reliable supplier of these abrasive tools. With its dedication to quality, innovation, and customer satisfaction, the company continues to set the standard for excellence in the industry and remains a top choice for businesses seeking high-quality flap brush wheels.

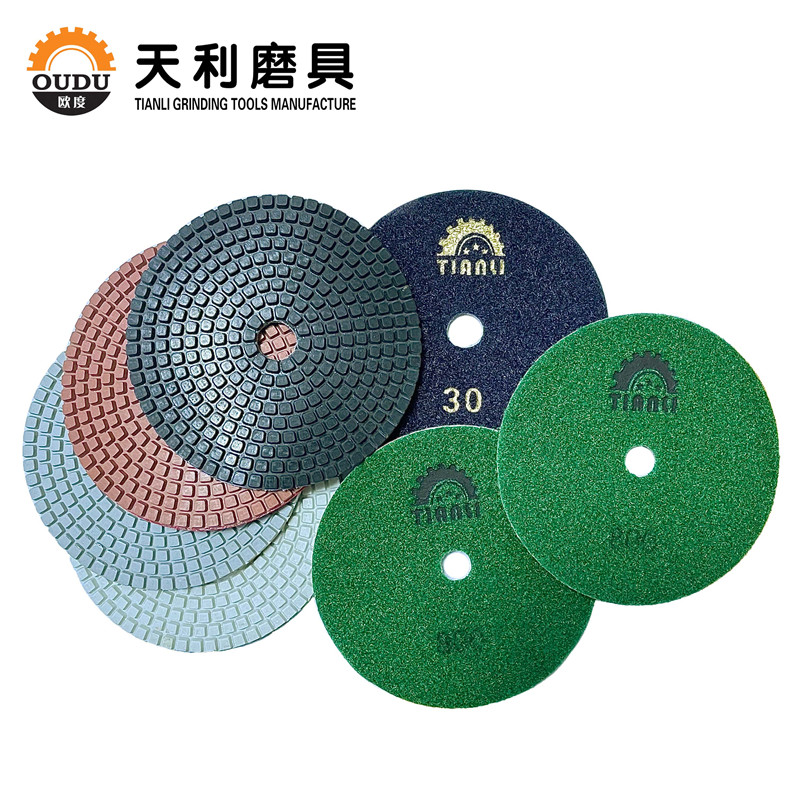

Durable and High-Quality Diamond Pads: A Must-have for Polishing and Grinding

Diamond Pads, a leading provider of high-quality cleaning and maintenance products, has recently released an innovative new line of cleaning pads that are designed to revolutionize the industry. These pads are made with the highest quality materials and are specially engineered to provide the best possible cleaning results. With this new product, Diamond Pads continues its tradition of excellence and commitment to providing the best cleaning solutions to its customers.The new line of cleaning pads by Diamond Pads features state-of-the-art technology that sets them apart from other cleaning pads on the market. These pads are made with diamond abrasives, which are known for their exceptional durability and effectiveness in cleaning a wide range of surfaces. The diamond abrasives are carefully embedded in the pads, ensuring that they provide maximum cleaning power while also minimizing the risk of scratching or damaging the surface being cleaned.In addition to their use of diamond abrasives, these pads are also engineered with a unique pattern that optimizes their cleaning effectiveness. This pattern helps to ensure that the pads make the most contact with the surface being cleaned, allowing for a more thorough and efficient cleaning process. As a result, users can expect to achieve superior cleaning results in less time and with less effort.One of the key benefits of the new line of cleaning pads by Diamond Pads is their versatility. These pads are designed to be compatible with a wide range of cleaning machines, making them suitable for use in various industries and applications. Whether it's for cleaning hard floors, stone surfaces, or even delicate marble, these pads are up to the task and can deliver exceptional results across the board.Furthermore, Diamond Pads is known for its commitment to sustainability and environmental responsibility. The company's new line of cleaning pads reflects this commitment, as they are made with eco-friendly materials and manufacturing processes. This means that customers can enjoy the superior cleaning power of these pads without having to compromise on their values or environmental impact.The release of this new line of cleaning pads underscores Diamond Pads' ongoing dedication to innovation and customer satisfaction. The company has a strong track record of developing cutting-edge cleaning products that deliver exceptional results, and these new pads are no exception. With their advanced technology, superior performance, and environmental focus, these pads are set to become a game-changer in the industry.In addition to their innovative new products, Diamond Pads also distinguishes itself through its commitment to customer service and support. The company takes pride in providing the highest level of service to its customers, and this extends to its new line of cleaning pads. Customers can expect reliable support, expert guidance, and a seamless experience when choosing and using these pads for their cleaning needs.With the release of its new line of cleaning pads, Diamond Pads is poised to make a significant impact in the industry. By combining cutting-edge technology, superior performance, and a commitment to sustainability, the company continues to raise the bar for cleaning products and set a new standard for excellence. Customers can look forward to experiencing the exceptional cleaning power of these pads and enjoying a more efficient and effective cleaning process as a result.

Understanding the Covalent Bond between Metals and Nonmetals

[Company Name] is a leading force in the world of chemical engineering and material science. With a focus on innovation and quality, the company has been at the forefront of developing new and advanced materials for a wide range of industries. One of their most recent breakthroughs has been in the area of covalent bond metal nonmetals, which has the potential to revolutionize the way we think about and use these materials.Covalent bonding is a type of chemical bond that involves the sharing of electron pairs between atoms. This type of bonding is typically seen in nonmetal elements, where the atoms are able to share electrons in order to achieve a stable electron configuration. Metals, on the other hand, typically form metallic bonds, where the atoms share a sea of electrons that flow freely throughout the material.The combination of covalent bond metal nonmetals brings together the best of both worlds, creating a material that has the strength and electrical conductivity of a metal, while also retaining the flexibility and lightweight properties of a nonmetal. This has the potential to open up new possibilities in a wide range of industries, from electronics and aerospace to healthcare and automotive.One of the key advantages of covalent bond metal nonmetals is their potential for use in electronics and electrical applications. These materials could be used to create more efficient and durable electrical components, leading to improved performance and reliability in a wide range of devices. In addition, the lightweight nature of these materials could also lead to advancements in the design and production of electronic devices, allowing for smaller and more compact designs without sacrificing performance.In the aerospace industry, the combination of covalent bond metal nonmetals could lead to the development of stronger and lighter materials for aircraft and spacecraft. This has the potential to greatly improve fuel efficiency and performance, leading to cost savings and environmental benefits for the industry. Additionally, the durability of these materials could also lead to longer-lasting and more reliable aircraft and spacecraft, improving safety and reducing maintenance costs.In the healthcare industry, covalent bond metal nonmetals could be used to create more advanced and durable medical devices and equipment. The strength and flexibility of these materials could lead to the development of new implantable devices and surgical tools, leading to improved outcomes for patients. Additionally, the lightweight nature of these materials could also lead to advancements in the design and production of medical devices, leading to more comfortable and effective treatments for patients.In the automotive industry, covalent bond metal nonmetals could be used to create stronger and lighter materials for vehicle construction. This has the potential to greatly improve fuel efficiency and performance, leading to cost savings and environmental benefits for the industry. Additionally, the durability of these materials could also lead to longer-lasting and more reliable vehicles, improving safety and reducing maintenance costs.With their groundbreaking work in the field of covalent bond metal nonmetals, [Company Name] is poised to make a significant impact in a wide range of industries. Their dedication to innovation and quality has led to the development of materials that have the potential to revolutionize the way we think about and use these important elements. As they continue to push the boundaries of what is possible in chemical engineering and material science, [Company Name] is sure to remain a driving force in the industry for years to come.

How to Use Marble Polish Pads for a Perfectly Polished Finish

Introducing the Latest Innovation in Marble Maintenance: The Marble Polish PadMarble is a timeless and elegant choice for flooring, countertops, and other surfaces in homes and businesses. Its natural beauty and durability make it a popular option for many people. However, maintaining the shine and luster of marble can be a challenge, especially in high-traffic areas. That's where the Marble Polish Pad comes in.The Marble Polish Pad is the latest innovation in marble maintenance, designed to make it easier than ever to keep marble surfaces looking their best. With its unique design and advanced technology, this product is set to revolutionize the way people care for their marble.The Marble Polish Pad is a specially designed pad that attaches to a floor buffer or polisher. It is made from high-quality materials that are gentle on marble surfaces, yet effective at removing dirt, grime, and surface imperfections. The pad is easy to use, making it suitable for both professional maintenance crews and DIY enthusiasts.The Marble Polish Pad is the brainchild of a reputable company that specializes in providing high-quality maintenance solutions for various surfaces. With a strong focus on innovation and customer satisfaction, this company has a long history of developing cutting-edge products that exceed industry standards.The company's commitment to excellence is evident in the design and performance of the Marble Polish Pad. It is the result of extensive research and development, as well as rigorous testing to ensure its effectiveness and safety for use on marble surfaces.The Marble Polish Pad is specially formulated to deliver outstanding results with minimal effort. Its unique composition allows it to gently remove surface imperfections and restore the natural shine of marble without causing damage or discoloration. This makes it an ideal solution for maintaining the beauty of marble surfaces in homes, hotels, restaurants, and other commercial settings.In addition to its exceptional performance, the Marble Polish Pad is also designed with user convenience in mind. It is easy to attach to a floor buffer or polisher, and its intuitive design allows for smooth and efficient operation. This means that users can achieve professional-quality results with minimal time and effort.Furthermore, the Marble Polish Pad is an environmentally friendly product that is designed to minimize its impact on the environment. It is made from sustainable materials and does not contain harsh chemicals that can be harmful to the planet or the user. This makes it a responsible choice for those looking to maintain their marble surfaces without compromising their environmental values.The Marble Polish Pad is set to revolutionize the way people care for their marble surfaces. With its innovative design, exceptional performance, and user-friendly features, it is poised to become the go-to solution for maintaining the beauty and durability of marble.Whether you are a homeowner looking to keep your marble floors looking their best or a professional maintenance crew responsible for the upkeep of commercial spaces, the Marble Polish Pad is the ideal choice for achieving outstanding results with ease. Its advanced technology and environmentally friendly design make it a reliable and effective solution for all marble maintenance needs.In conclusion, the Marble Polish Pad is a game-changing product that is poised to set a new standard for marble maintenance. With its exceptional performance, user-friendly design, and environmental responsibility, it is the ultimate solution for keeping marble surfaces looking their best. Whether used in homes or commercial settings, the Marble Polish Pad is a must-have for anyone looking to preserve the timeless beauty of marble.

High-Quality Concrete Buffing Pads for Professional Polishing

Home renovation projects are on the rise around the country as more and more homeowners are choosing to improve and upgrade their living spaces. One popular area of focus for many of these projects is the flooring, with polished concrete flooring gaining popularity for its durability and modern aesthetic. In order to achieve the desired sleek and shiny finish for concrete floors, many contractors and DIY enthusiasts are turning to high-quality buffing pads, such as the ones offered by [Company Name].[Company Name] is a leading provider of concrete buffing pads and other surface preparation tools and accessories. With years of industry experience and a commitment to providing top-notch products, [Company Name] has become a trusted name in the construction and renovation industry. Their range of concrete buffing pads is known for its superior performance and durability, making them the go-to choice for professionals and hobbyists alike.The concrete buffing pads offered by [Company Name] are designed to be used with various floor polishing machines, making them suitable for a wide range of projects and applications. Whether it's a small residential floor or a large commercial space, [Company Name] has the right set of pads to achieve the desired results. Their products are manufactured using high-quality materials and advanced manufacturing processes, ensuring that they can withstand the rigors of concrete polishing and deliver consistent performance.One of the key features that sets [Company Name]'s concrete buffing pads apart from the competition is their superior diamond-infused design. The diamond particles embedded in the pads enable them to effectively remove scratches, stains, and blemishes from concrete surfaces, leaving behind a smooth and glossy finish. This innovative design ensures that contractors and DIYers can achieve professional-level results without having to invest in expensive equipment or hire external services.In addition to their exceptional performance, [Company Name]'s concrete buffing pads are also lauded for their long service life. The high-quality construction and carefully selected materials ensure that the pads can withstand heavy use and frequent reconditioning without deteriorating in quality. This makes them a cost-effective choice for both professionals and enthusiasts who are looking for durable and reliable surface preparation tools.Furthermore, [Company Name] is dedicated to providing outstanding customer service and support, ensuring that their clients have access to the information and resources they need to make the most of their products. Their team of experts is always on hand to offer advice and guidance on using the concrete buffing pads, as well as recommendations for specific projects and applications. This commitment to customer satisfaction has helped [Company Name] build a loyal and satisfied customer base, further cementing their reputation as a trusted provider of surface preparation tools.As the demand for polished concrete flooring continues to grow, [Company Name] is poised to meet the needs of contractors and DIY enthusiasts with their high-quality buffing pads and unwavering dedication to customer satisfaction. With a focus on performance, durability, and customer support, [Company Name] has solidified its position as a leader in the industry and remains a go-to choice for anyone looking to achieve professional-level results in concrete floor polishing. Whether it's a small residential project or a large-scale commercial renovation, [Company Name] has the tools and expertise to help their clients achieve their goals.

Top Abrasive Manufacturers: A Comprehensive Guide to Choosing the Right Supplier

A leading abrasive manufacturer has made significant strides in the industry, showcasing its commitment to innovation and excellence. With a strong focus on quality and customer satisfaction, the company has set itself apart as a trusted provider of high-performance abrasives for a wide range of industrial applications.Established over [number] years ago, the company has grown to become a key player in the abrasive manufacturing sector, serving clients in various industries including automotive, aerospace, metal fabrication, and construction. The company's extensive product line includes a diverse range of abrasive materials such as bonded abrasives, coated abrasives, and superabrasives, all of which are designed to deliver exceptional results in precision grinding, cutting, and surface finishing.One of the company's core strengths lies in its relentless pursuit of innovation. Through ongoing research and development efforts, the company continues to introduce cutting-edge abrasive solutions that offer enhanced performance, durability, and cost-effectiveness. By leveraging advanced manufacturing technologies and materials, the company has been able to stay ahead of the curve in meeting the evolving needs of its customers.In addition to its focus on product innovation, the company places a strong emphasis on quality control and assurance. This commitment to excellence is evident in the company's state-of-the-art manufacturing facilities and rigorous quality testing processes, which ensure that each batch of abrasives meets the highest standards of consistency and performance.Furthermore, the company's dedication to customer satisfaction is reflected in its comprehensive technical support and customized solutions. With a team of experienced engineers and technical experts, the company is able to provide valuable assistance to clients in choosing the right abrasive products for their specific applications. Whether it's optimizing cutting parameters, troubleshooting surface finishing issues, or recommending the most suitable abrasives for a particular material, the company's technical support team is always ready to offer expert guidance and assistance.Another key aspect of the company's success is its commitment to sustainability and environmental responsibility. In an industry where waste and environmental impact are of growing concern, the company has taken proactive measures to minimize its carbon footprint and reduce waste generation. From utilizing eco-friendly manufacturing processes to promoting the use of recyclable materials, the company is dedicated to operating in an environmentally sustainable manner.Beyond its commitment to excellence, innovation, and sustainability, the company also prides itself on its strong corporate values and ethical business practices. With a focus on integrity, transparency, and fair business dealings, the company has earned a solid reputation for reliability and trustworthiness in the industry.Looking ahead, the company remains steadfast in its commitment to pushing the boundaries of abrasive technology and delivering superior solutions to its customers. With a strong focus on continuous improvement and a customer-centric approach, the company is well-positioned to maintain its leadership in the abrasive manufacturing sector and drive further growth and success in the years to come.