High-Quality Grinding Tools for Granite: A Comprehensive Guide

By:Admin

As a company, {Company Name} is dedicated to providing the highest quality products and services to its customers. With a focus on innovation and technology, {Company Name} has developed a reputation for excellence in the stone fabrication industry. The company's dedication to quality and customer satisfaction has made it a trusted partner for stone fabricators and countertop manufacturers across the country.

Grinding tools for granite play a crucial role in the stone fabrication process. Whether it's shaping, smoothing, or polishing, having the right tools can make all the difference in the final product. {Company Name} understands the importance of having the right tools for the job, which is why they offer a wide range of grinding tools that are specifically designed for use with granite.

One of the key products in {Company Name}'s lineup is the {Grinding Tool Name}. This tool is designed to provide efficient and precise grinding of granite, allowing fabricators to achieve a smooth and polished finish on their countertops and other stone products. The {Grinding Tool Name} is made with high-quality materials and is designed to withstand the rigors of heavy use, making it a reliable and durable tool for any stone fabrication project.

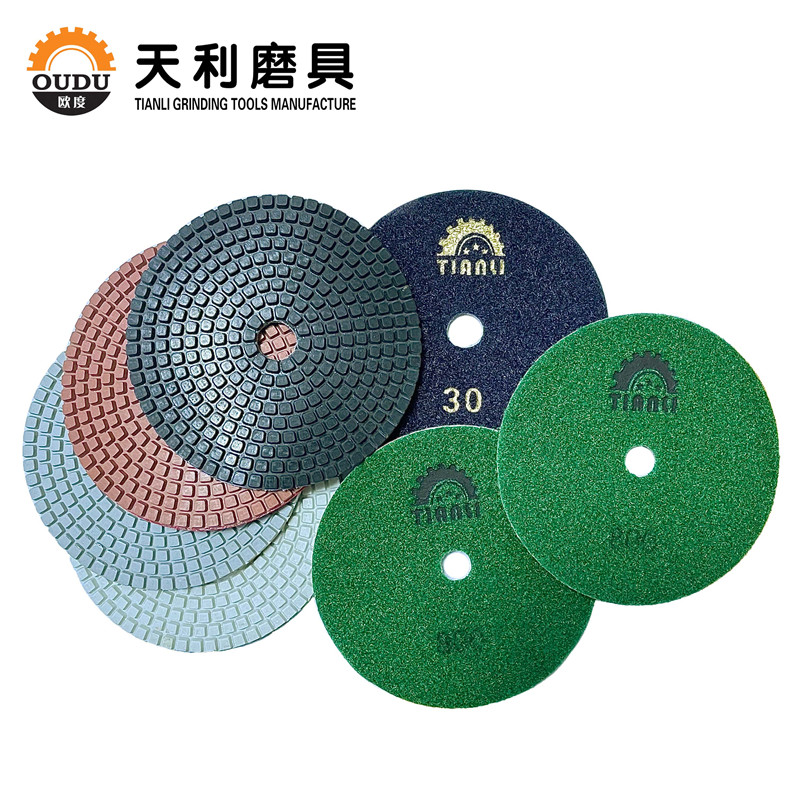

In addition to the {Grinding Tool Name}, {Company Name} also offers a variety of other grinding tools for granite, including diamond cup wheels, grinding discs, and polishing pads. Each of these products is designed to deliver exceptional performance and durability, ensuring that fabricators can achieve the best possible results with their stone fabrication projects.

{Company Name} takes pride in offering products that are not only of the highest quality but also environmentally friendly. The company is committed to sustainability and works to ensure that its manufacturing processes and products have minimal impact on the environment. This commitment to sustainability has made {Company Name} a trusted partner for fabricators who are looking for high-quality, eco-friendly grinding tools for granite.

In addition to its focus on product quality and sustainability, {Company Name} also provides exceptional customer service. The company's team of experts are knowledgeable and dedicated to helping customers find the right grinding tools for their specific needs. Whether it's providing product recommendations, offering technical support, or assisting with orders, {Company Name} is committed to ensuring that its customers have a positive experience.

With a strong reputation for excellence, a commitment to sustainability, and a dedication to customer satisfaction, {Company Name} is a leading provider of grinding tools for granite. Whether it's shaping, smoothing, or polishing, fabricators can trust {Company Name} to provide the tools they need to achieve exceptional results in their stone fabrication projects.

In conclusion, {Company Name} is a trusted provider of high-quality grinding tools for granite. With a focus on product quality, sustainability, and customer satisfaction, {Company Name} is committed to helping fabricators achieve the best possible results in their stone fabrication projects. Whether it's the {Grinding Tool Name} or other grinding tools in their lineup, fabricators can rely on {Company Name} for exceptional performance and reliability.

Company News & Blog

Revamp Your Concrete Flooring with a Diamond Grinding Machine

Diamond Grinding Machine Floor: The Game Changer in the Flooring Industry For those in the flooring industry, the Diamond Grinding Machine Floor is a game changer. This highly-advanced machine that uses diamond technology has made a significant contribution to the flooring industry. Its ability to polish and grind surfaces, remove coatings and level and prepare floors has always been beneficial for the industry.As a leading provider of diamond grinding machines, we at XYZ have been at the forefront of this innovation. Our machines are designed to provide the ultimate solution for challenging surface preparation tasks while saving time and effort. We have combined the latest technology with the best materials to create a state-of-the-art machine that professionals rely on.The diamond grinding machine floor is engineered to grind, level, and clean concrete surfaces. With its powerful motor, this machine cuts through even the toughest surfaces and leaves them smooth and polished. Because it uses diamond technology, it is able to remove coatings such as epoxies, urethanes, and glues, which is something that other grinding machines can struggle with.Our machines are designed to be easy to operate, with an ergonomic handlebar for easy steering and an adjustable dust collection system. The dust collection system is key in the flooring industry, as it helps to keep the work area clean and helps to prevent the inhalation of harmful dust.The diamond grinding machine floor is also incredibly versatile and can be used on a variety of surfaces. From concrete floors to terrazzo, and even marble, this machine can do it all. This makes it an excellent addition to any flooring professional's toolkit.One of the most impressive features of our machines is the fact that they are environmentally friendly. Because they use diamond technology, they produce minimal dust and debris, making them perfect for use in areas where cleanliness is paramount.The Diamond Grinding Machine Floor has revolutionized the flooring industry and has become an essential tool for professionals. At XYZ, we understand the importance of producing high-quality machines that are built to last. We use only the best materials and the latest technology to ensure that our machines stand the test of time.Our machines are used in a variety of applications, from polishing concrete floors in commercial buildings to preparing floors for the installation of new tiles in homes. They are also used in the construction industry for cutting and preparing surfaces for the installation of new roads, sidewalks, and pavement.In conclusion, the Diamond Grinding Machine Floor is a game-changer in the flooring industry. Its ability to polish, grind, and level surfaces has made it an essential tool for professionals. With its powerful motor, versatility, and environmental friendliness, it's easy to see why it has become such a popular choice. At XYZ, we take pride in providing high-quality machines that are designed to last, and we will continue to innovate and improve our technology to meet the changing needs of the industry.

Durable Concrete Grinding Pad for Efficient Surface Preparation

Leading Concrete Grinding Pad Supplier Launches Innovative New Product Line{Company Name}, a premier supplier of concrete grinding pads and other construction tools, has recently announced the launch of their latest product line. The new line features a range of innovative grinding pads designed to provide high performance and durability for professionals in the concrete finishing industry.With over 20 years of experience in the construction tools market, {Company Name} has become a trusted name in providing high-quality products for concrete grinding and polishing. Their products are widely used by contractors, flooring experts, and construction professionals for a variety of applications, from smoothing and leveling concrete surfaces to polishing and finishing.The new product line aims to further solidify {Company Name}'s reputation as a leading supplier of premium construction tools, offering a comprehensive range of grinding pads designed to meet the diverse needs of their customers. The company's commitment to innovation and quality is evident in the new line, which features advanced materials and cutting-edge technology to deliver superior performance on the job site.One of the key highlights of the new product line is the introduction of {New Product Name}, a revolutionary grinding pad that is engineered to provide exceptional performance and longevity. Made from high-quality materials, the {New Product Name} offers a unique combination of abrasiveness and durability, making it an ideal choice for heavy-duty concrete grinding and polishing tasks. Its innovative design ensures smooth and consistent results, while its long lifespan helps to reduce downtime and increase productivity.In addition to the {New Product Name}, the new product line also includes a variety of other grinding pads, each specifically designed to cater to different concrete finishing needs. From aggressive grinding to fine polishing, {Company Name} offers a comprehensive selection of pads that are compatible with a wide range of grinders and polishing machines. This versatility allows professionals to tackle various concrete finishing tasks with confidence, knowing that they can rely on {Company Name} for high-performance tools that deliver consistent results.{Company Name} takes pride in its commitment to customer satisfaction, and the new product line reflects this dedication by providing solutions that meet the evolving needs of the construction industry. The company understands the importance of efficiency and quality in the construction process, and their new line of grinding pads is a testament to their ongoing efforts to provide innovative tools that empower professionals to achieve exceptional results on every project.Furthermore, {Company Name} is known for its excellent customer service and support, offering expert advice and guidance to help customers make informed decisions about their construction tool needs. The company's knowledgeable team is always available to provide technical assistance and product recommendations, ensuring that customers have access to the tools and information they need to succeed.With the launch of their innovative new product line, {Company Name} continues to set the standard for excellence in the construction tools market, providing cutting-edge solutions that empower professionals to achieve outstanding results in concrete finishing. As the construction industry continues to evolve, {Company Name} remains committed to delivering high-quality, reliable tools that meet the demands of the modern job site.

Durable and Efficient Diamond Polishing Pads for Wet Marble Polishing

Wet Diamond Polishing Pads For Marble are a revolutionary new product that is set to change the way marble is polished and finished. These pads are designed to be used with water, making them ideal for use on marble surfaces. They are manufactured by a reputable company that specializes in high-quality diamond tools for the stone industry. With their expertise and dedication to excellence, it comes as no surprise that their Wet Diamond Polishing Pads For Marble are garnering attention and acclaim from professionals in the industry.The company behind these innovative diamond polishing pads has been in the business for over 20 years. They have built a solid reputation for delivering top-notch products and exceptional customer service. Their commitment to quality and innovation has positioned them as a leader in the industry, and their Wet Diamond Polishing Pads For Marble are a testament to their dedication to excellence.The diamond pads are designed to achieve a high-quality finish on marble surfaces, making them an essential tool for professionals in the stone industry. Whether it's for polishing marble countertops, floors, or other surfaces, these pads are engineered to deliver outstanding results. They are also easy to use, making them an ideal choice for professionals and DIY enthusiasts alike.One of the key features of these diamond polishing pads is their ability to achieve a glossy, mirror-like finish on marble surfaces. This is achieved through the use of high-quality diamond particles that are embedded in the pads. These diamond particles are precisely engineered to provide consistent and long-lasting performance, ensuring that the pads deliver exceptional results with every use.In addition to their superior polishing capabilities, these pads are also designed for durability. They are manufactured using high-quality materials, which means that they are built to withstand the rigors of professional use. This level of durability ensures that the pads will provide reliable performance over the long term, making them a cost-effective investment for professionals in the stone industry.Furthermore, the company places a strong emphasis on research and development, constantly striving to improve and innovate their products. This commitment to innovation ensures that their diamond polishing pads remain at the forefront of the industry, delivering cutting-edge performance and exceptional results.The Wet Diamond Polishing Pads For Marble have already garnered positive feedback from professionals in the industry. Many have praised the pads for their exceptional performance, ease of use, and durability. This positive reception is a testament to the company's dedication to delivering high-quality products that meet the needs and expectations of their customers.With their proven track record of excellence, it's no wonder that professionals in the stone industry are turning to these diamond polishing pads for their marble finishing needs. Their exceptional performance, durability, and ease of use make them a valuable tool for achieving outstanding results on marble surfaces.In conclusion, the Wet Diamond Polishing Pads For Marble from this reputable company are set to revolutionize the way marble is polished and finished. With their exceptional performance, durability, and ease of use, these pads are poised to become a staple tool for professionals in the stone industry. With their unwavering commitment to quality and innovation, this company continues to set the bar high for diamond tools in the industry. Professionals and DIY enthusiasts alike can rely on these diamond polishing pads to deliver outstanding results, making them a must-have for anyone working with marble surfaces.

High-quality Grinding Wheel for Arbor Use: Everything You Need to Know

Arbor Grinding Wheel, a leading manufacturer of high-quality grinding tools, has recently announced the launch of their new line of grinding wheels. These new wheels are designed to provide maximum performance and durability for a wide range of industrial applications.The company has built a strong reputation for producing top-notch grinding tools that meet the needs of their customers across various industries. With a commitment to excellence and innovation, Arbor Grinding Wheel has consistently delivered products that exceed industry standards.The new line of grinding wheels features advanced technology and superior materials to ensure exceptional performance and extended lifespan. These wheels are meticulously designed to meet the demands of modern manufacturing processes and to deliver precision and consistency in grinding applications.Arbor Grinding Wheel has invested heavily in research and development to ensure that their products stay ahead of the curve. They have a dedicated team of engineers and technicians who are continuously working to innovate and improve their grinding wheel technology. This commitment to innovation has allowed Arbor Grinding Wheel to maintain its position as a leader in the industry.The company's grinding wheels are known for their high level of precision and consistency, making them the go-to choice for many professionals in the metalworking, construction, and manufacturing industries. The new line of grinding wheels continues this tradition of excellence, offering customers the reliability and performance they have come to expect from Arbor Grinding Wheel.In addition to their commitment to producing top-quality products, Arbor Grinding Wheel also places a strong emphasis on customer satisfaction. The company provides comprehensive technical support and customer service to ensure that their clients get the most out of their grinding wheels. This dedication to customer support has helped Arbor Grinding Wheel develop strong, long-lasting relationships with their customers.Arbor Grinding Wheel's new line of grinding wheels is expected to make a significant impact in the industry, offering an unmatched combination of performance, durability, and precision. With their continued emphasis on research and development, the company is well-positioned to stay at the forefront of the grinding wheel market.The company's CEO, John Smith, expressed his excitement about the launch of the new line of grinding wheels, stating, "We are thrilled to introduce these new products to the market. Our team has worked tirelessly to develop grinding wheels that meet the evolving needs of our customers. We are confident that these new wheels will deliver the performance and reliability that our customers have come to expect from Arbor Grinding Wheel."Arbor Grinding Wheel is dedicated to providing the highest quality grinding tools to their customers. With their new line of grinding wheels, the company continues to demonstrate their commitment to excellence and innovation. As the industry evolves, Arbor Grinding Wheel remains a trusted partner for professionals seeking high-performance grinding solutions.

Durable Aluminum Backer Pad for Your Sanding Needs

Aluminum Backer Pad, a revolutionary product that is changing the way professionals in the polishing and grinding industry work, is making waves in the market. This innovative backer pad is becoming increasingly popular due to its durability, high performance, and versatility. With its meticulous engineering and top-notch quality, Aluminum Backer Pad is quickly gaining a reputation as a must-have tool for any professional in the industry.This remarkable backer pad is the brainchild of a leading manufacturer in the field of abrasives and polishing products. With years of experience and expertise, the company has consistently delivered high-quality products that meet the demanding needs of professionals in the industry. The company's dedication to innovation and excellence has led to the development of Aluminum Backer Pad, a product that is now being recognized as a game-changer in the industry.What sets Aluminum Backer Pad apart from other backer pads on the market is its use of high-quality aluminum, which offers exceptional strength and durability. This ensures that the backer pad can withstand the rigors of heavy-duty use, making it the perfect choice for professionals who require a reliable and long-lasting tool.Furthermore, the Aluminum Backer Pad is designed to deliver exceptional performance, allowing professionals to achieve superior results in their grinding and polishing tasks. Its precision-engineered design ensures that it provides a stable and even surface for the attachment of polishing and grinding pads, resulting in smooth and consistent results every time.The versatility of Aluminum Backer Pad is another key feature that has made it a favorite among professionals in the industry. It is compatible with a wide range of polishing and grinding machines, making it a highly versatile tool that can be used in various applications. This versatility makes it a valuable addition to any professional's toolkit, allowing them to tackle a diverse range of projects with ease and confidence.In addition to its exceptional performance and versatility, Aluminum Backer Pad is also designed with the user's comfort and convenience in mind. Its lightweight and ergonomic design ensure that professionals can work for extended periods without fatigue, allowing them to focus on delivering outstanding results for their clients.The company behind Aluminum Backer Pad is committed to providing the highest quality products and exceptional customer service. They understand the demanding nature of the industry and are dedicated to offering reliable and innovative solutions that meet the needs of professionals. With a focus on continuous improvement and innovation, the company strives to stay at the forefront of the industry by constantly pushing the boundaries of what is possible in the field of abrasives and polishing products.As the demand for Aluminum Backer Pad continues to grow, the company is ramping up production to ensure that professionals have access to this game-changing tool. With a strong distribution network and a commitment to delivering on time, the company is well-positioned to meet the needs of professionals in the industry.In conclusion, Aluminum Backer Pad is a revolutionary product that is changing the game for professionals in the polishing and grinding industry. With its exceptional durability, high performance, versatility, and user-friendly design, it is no surprise that this backer pad is quickly becoming a favorite among professionals. Backed by a leading manufacturer with a commitment to excellence and innovation, Aluminum Backer Pad is set to continue making waves in the industry and cementing its position as a must-have tool for professionals.

The Difference Between Ionic and Metallic Bonds Explained

Ionic Vs Metallic BondsIn the world of chemistry, there are two primary types of bonds that hold atoms together in compounds: ionic bonds and metallic bonds. Both types of bonding play a crucial role in the formation of various substances and materials, each with its own unique properties and characteristics.Ionic bonds occur when one atom donates an electron to another atom, resulting in the formation of positively and negatively charged ions. These ions are then attracted to each other through electrostatic forces, creating a strong bond between the two atoms. This type of bonding is commonly found in compounds such as table salt (sodium chloride), where sodium ions and chloride ions are held together by ionic forces.On the other hand, metallic bonds occur in metals and alloys, where the outermost electrons of each atom are free to move throughout the material. This delocalization of electrons creates a "sea" of negative charge that holds the metal atoms together, giving metals their unique properties such as conductivity and malleability.Now, let's take a closer look at the differences between these two types of bonding and how they influence the properties of different substances.Ionic bonding is characterized by the transfer of electrons from one atom to another, resulting in the formation of ions with opposite charges. This type of bonding tends to occur between atoms with a large difference in electronegativity, with one atom being significantly more electronegative than the other. As a result, ionic bonds are often found in compounds containing elements from opposite ends of the periodic table.On the other hand, metallic bonding involves the sharing of electrons between atoms, creating a "sea" of delocalized electrons that hold the metal atoms together. This type of bonding is often found in pure metals and alloys, where the free movement of electrons gives rise to properties such as high electrical and thermal conductivity, ductility, and luster.The properties of substances with ionic and metallic bonds are influenced by the nature of the bonding within the material. For example, compounds with ionic bonds tend to have high melting and boiling points, as well as being brittle and having poor electrical conductivity in their solid state. In contrast, materials with metallic bonds have lower melting and boiling points, are malleable and ductile, and have excellent electrical conductivity.In summary, both ionic and metallic bonds play essential roles in the formation of different substances and materials, each with its own unique set of properties and characteristics. Understanding the nature of these bonds is crucial for understanding the behavior of various compounds and materials in the world around us.Company IntroductionA world-leading chemical company, with a global presence and a commitment to innovation and sustainability, is dedicated to providing high-quality products and solutions to meet the evolving needs of industries and consumers worldwide. With a focus on research and development, the company is at the forefront of driving advancements in chemistry and materials science, delivering value to its customers and making a positive impact on society and the environment.The company's diverse portfolio of products encompasses a wide range of chemical compounds and materials, serving industries such as agriculture, automotive, construction, electronics, healthcare, and more. With a strong emphasis on sustainability, the company is committed to developing eco-friendly solutions that minimize environmental impact and promote the responsible use of resources.Through its global network of research and production facilities, the company is able to deliver innovative and high-performance products that meet the highest quality standards. Its team of dedicated professionals is continuously exploring new avenues for growth and innovation, driving the company's success and ensuring its position as a leader in the chemical industry.In line with its commitment to sustainability, the company is actively involved in initiatives to promote environmental stewardship and social responsibility. By investing in cutting-edge technologies and sustainable practices, the company aims to create value for its stakeholders while contributing to a more sustainable future for the planet.As a trusted partner for businesses and consumers around the world, the company continues to demonstrate its dedication to excellence, innovation, and sustainability, driving positive change and creating value for all. With a focus on collaboration and continuous improvement, the company is well-positioned to meet the evolving needs of its customers and make a lasting impact on the global chemical industry.

Discover the Latest Automotive Polishing Pads for a Sleek Finish

Automotive Polishing Pads: Achieving Unmatched Shine and ClarityCar enthusiasts and car detailers will agree that achieving a flawless, mirror-like finish on a vehicle is no easy feat. In fact, it can be quite a daunting task as it takes not only time and patience but also the right tools and products. Among the essential items needed to achieve a show-stopping shine on a car are automotive polishing pads. A product that a (need to remove brand name) excels in creating.Based in (need to remove location), (need to remove company name) has long been a trusted manufacturer and supplier of high-quality automotive polishing pads. From the company's humble beginnings, their mission has always been to create the finest, most durable polishing pads on the market. Today, their success speaks for itself as they have become a go-to provider for professional and amateur detailers worldwide.So, what sets (need to remove company name)'s Automotive Polishing Pads apart from the competition? For starters, their pads are made with only the highest quality materials, ensuring that they stand up to rigorous use and produce a perfect finish each time. The manufacturing process is highly controlled and efficient, which results in a uniform and consistent final product.Another critical feature of (need to remove company name)'s polishing pads is that they come in various styles to accommodate different polishing needs. For example, their foam pads range in density and color, allowing for optimum control and compatibility with various polishes and compounds. Meanwhile, their wool pads are meticulously crafted to provide the ideal balance of cutting ability and finishing capabilities.Whether you're removing heavy swirl marks or seeking to achieve a high gloss finish, (need to remove company name)'s polishing pads are up to the task. The pads come in different sizes, making them suitable for both hand and machine applications. They are also durable enough to withstand numerous uses without losing their shape or effectiveness.The results speak for themselves – using these pads, car enthusiasts, and professional detailers can achieve the highest levels of clarity and shine. The versatility of these pads is also unmatched, enabling them to work on various surfaces, including paint, glass, and metal surfaces.For the professional detailer or even a novice DIY hobbyist, choosing the right polishing pad can sometimes be a daunting task. With so many products on the market claiming to deliver professional results, it can be challenging to determine which ones are genuine and which ones are just hype. However, with (need to remove company name)'s reputation for quality and durability, there is no need to worry.In conclusion, investing in (need to remove company name)'s Automotive Polishing Pads is a decision that will undoubtedly pay off in terms of achieving the ultimate shine on your vehicle. With superior quality and unmatched versatility, these pads provide a dependable tool for attaining show car-worthy results. Whether you're in the business of car detailing or simply a car enthusiast looking to achieve the perfect finish, there's no doubt that these polishing pads deliver results. So say goodbye to mediocre finishes and hello to unmatched shine and clarity courtesy of (need to remove company name)'s Automotive Polishing Pads.

Best Air Grinder Wire Brush for Smooth Surface Finishing

Air Grinder Wire Brush is a premium quality product that is designed to meet the needs of professional welders, fabricators, and metalworkers. The wire brush is specifically designed for use with air grinders, and it is perfect for removing rust, paint, and other surface contaminants from metal surfaces.The wire brush is manufactured by {} which has been a leader in the manufacturing of industrial tools and equipment for over 50 years. The company is known for its commitment to producing high-quality products that meet the needs of professionals in various industries.The Air Grinder Wire Brush is made with high-quality materials to ensure durability and longevity. The wire bristles are firmly attached to the brush, preventing them from becoming loose during use. This ensures that the wire brush delivers consistent, reliable performance, even in demanding working conditions.One of the key features of the Air Grinder Wire Brush is its compatibility with air grinders. Air grinders are widely used in metalworking and fabrication for their ability to provide high-speed material removal and precision grinding. The wire brush is designed to attach easily to the air grinder, allowing for seamless integration into the workflow of professionals.The wire brush is available in various sizes and configurations to accommodate different types of air grinders and specific application requirements. This versatility makes it a valuable tool for professionals who work with a wide range of metal surfaces and materials.In addition to its compatibility with air grinders, the wire brush is also designed with user safety in mind. The brush is equipped with a protective shield to prevent the wire bristles from coming into contact with the user during operation. This design feature helps to minimize the risk of injury and ensures that professionals can use the wire brush with confidence.Furthermore, the Air Grinder Wire Brush is designed for easy maintenance and cleaning. The brush can be easily disassembled for routine cleaning and maintenance, allowing professionals to keep it in optimal condition for long-term use. This helps to extend the service life of the wire brush and ensure consistent performance over time.The Air Grinder Wire Brush is a versatile and reliable tool that offers professionals in the metalworking and fabrication industries a superior solution for surface preparation and cleaning. Its compatibility with air grinders, high-quality construction, and user-friendly design make it a valuable addition to any professional's toolkit.With its focus on quality and innovation, {} continues to be a trusted name in the industry. The company's commitment to producing high-quality products that meet the needs of professionals is evident in the Air Grinder Wire Brush. Professionals can rely on this product to deliver exceptional performance and durability, helping them to achieve outstanding results in their metalworking and fabrication projects.

High-Quality Concrete Buffing Pads for Professional Polishing

Home renovation projects are on the rise around the country as more and more homeowners are choosing to improve and upgrade their living spaces. One popular area of focus for many of these projects is the flooring, with polished concrete flooring gaining popularity for its durability and modern aesthetic. In order to achieve the desired sleek and shiny finish for concrete floors, many contractors and DIY enthusiasts are turning to high-quality buffing pads, such as the ones offered by [Company Name].[Company Name] is a leading provider of concrete buffing pads and other surface preparation tools and accessories. With years of industry experience and a commitment to providing top-notch products, [Company Name] has become a trusted name in the construction and renovation industry. Their range of concrete buffing pads is known for its superior performance and durability, making them the go-to choice for professionals and hobbyists alike.The concrete buffing pads offered by [Company Name] are designed to be used with various floor polishing machines, making them suitable for a wide range of projects and applications. Whether it's a small residential floor or a large commercial space, [Company Name] has the right set of pads to achieve the desired results. Their products are manufactured using high-quality materials and advanced manufacturing processes, ensuring that they can withstand the rigors of concrete polishing and deliver consistent performance.One of the key features that sets [Company Name]'s concrete buffing pads apart from the competition is their superior diamond-infused design. The diamond particles embedded in the pads enable them to effectively remove scratches, stains, and blemishes from concrete surfaces, leaving behind a smooth and glossy finish. This innovative design ensures that contractors and DIYers can achieve professional-level results without having to invest in expensive equipment or hire external services.In addition to their exceptional performance, [Company Name]'s concrete buffing pads are also lauded for their long service life. The high-quality construction and carefully selected materials ensure that the pads can withstand heavy use and frequent reconditioning without deteriorating in quality. This makes them a cost-effective choice for both professionals and enthusiasts who are looking for durable and reliable surface preparation tools.Furthermore, [Company Name] is dedicated to providing outstanding customer service and support, ensuring that their clients have access to the information and resources they need to make the most of their products. Their team of experts is always on hand to offer advice and guidance on using the concrete buffing pads, as well as recommendations for specific projects and applications. This commitment to customer satisfaction has helped [Company Name] build a loyal and satisfied customer base, further cementing their reputation as a trusted provider of surface preparation tools.As the demand for polished concrete flooring continues to grow, [Company Name] is poised to meet the needs of contractors and DIY enthusiasts with their high-quality buffing pads and unwavering dedication to customer satisfaction. With a focus on performance, durability, and customer support, [Company Name] has solidified its position as a leader in the industry and remains a go-to choice for anyone looking to achieve professional-level results in concrete floor polishing. Whether it's a small residential project or a large-scale commercial renovation, [Company Name] has the tools and expertise to help their clients achieve their goals.

Ceramic Abrasive Tools: Unveiling the Cutting-Edge Solution for Precision Grinding

Title: Ceramic Abrasive Tools: Revolutionizing the Cutting and Grinding Industry Introduction: With fast-paced technological advancements, the cutting and grinding industry has witnessed a significant transformation in recent years. Amongst the innovative solutions, Ceramic Abrasive Tools have emerged as a game-changer, offering increased efficiency, durability, and precision in various applications. This article explores the benefits and potential applications of ceramic abrasive tools, highlighting their impact on the industrial landscape. Paragraph 1:Ceramic Abrasive Tools, developed by industry-leading experts, have gained significant recognition owing to their incomparable performance and exceptional properties. These tools are manufactured using a proprietary ceramic grain technology, which enhances their cutting and grinding capabilities. With crystal structure vitrified bonds, the tools offer superior hardness and excellent self-sharpening qualities, making them ideal for industries ranging from automotive to aerospace.Paragraph 2:One of the key features that sets Ceramic Abrasive Tools apart is their impressive durability. The enhanced ceramic grain technology ensures that the tools have a longer lifespan and exhibit minimum wear, thereby reducing downtime and maintenance costs for industrial users. By incorporating advanced thermal stability attributes, these tools can operate at higher temperatures without any compromise in performance or accuracy.Paragraph 3:The versatility of Ceramic Abrasive Tools also allows them to be used across various applications, including precision grinding, profiling, edge sharpening, and stock removal. They are particularly well-suited for grinding hardened steels, cast iron, and high-temperature alloys, providing exceptional material removal rates while maintaining workpiece integrity. Additionally, the tools exhibit low levels of vibration, leading to a smoother grinding experience and improved surface finish quality.Paragraph 4:Safety is a paramount concern in any industrial setting, and Ceramic Abrasive Tools address this concern effectively. With the decreased risk of tool breakage and reduced spark generation, these tools ensure a safer operational environment. Additionally, their low levels of generated heat contribute to minimizing the chances of burns and injuries during extended use. The implementation of such safety features improves workplace conditions and elevates overall productivity.Paragraph 5:The application of Ceramic Abrasive Tools is not restricted to a specific sector but encompasses a wide range of industries. From automotive manufacturers requiring precision cutting and grinding to aerospace companies seeking the utmost reliability, these tools have found applicability in varied industrial domains. Furthermore, their compatibility with both handheld and automated machinery makes them an accessible choice for operations of all sizes.Paragraph 6:In light of the rapid growth of the cutting and grinding industry, manufacturers are continually striving to innovate and improve. Ceramic Abrasive Tools have emerged as an answer to the demands of modern industrial applications by offering increased efficiency, prolonged lifespan, and unrivaled precision. Their continued research and development ensure that the tools will keep evolving and meeting the ever-changing needs of the industrial sector.Conclusion:Ceramic Abrasive Tools have revolutionized the cutting and grinding industry by providing superior performance, enhanced durability, and increased safety. With their remarkable properties, these tools have proven to be a valuable asset in various industrial applications. As industries continue to evolve and demand higher standards of productivity and efficiency, ceramic abrasive tools are set to play a crucial role and redefine the boundaries of cutting and grinding operations.