High-Quality Aluminum Oxide Grinding Wheel for Precision Grinding

By:Admin

Grinding wheels are a crucial tool in the manufacturing and metalworking industries, commonly used for sharpening, shaping, or finishing metal surfaces. One of the most widely used types of grinding wheels is the Aluminum Oxide Grinding Wheel. This type of grinding wheel is made with aluminum oxide as the abrasive material, which gives it strong cutting abilities and high durability.

The Aluminum Oxide Grinding Wheel is designed for a wide range of applications, including surface grinding, cylindrical grinding, and tool and cutter grinding. It is suitable for grinding metals such as steel, cast iron, and non-ferrous metals. The wheel's composition and grain size make it effective for removing stock quickly and delivering an excellent surface finish.

The company behind the Aluminum Oxide Grinding Wheel is a leading manufacturer of abrasives and abrasive products, specializing in providing high-quality solutions for industrial grinding and finishing applications. The company has a long history of innovation and excellence in the field of abrasives, and its products are trusted by professionals in industries ranging from metalworking and manufacturing to construction and maintenance.

With a commitment to quality and customer satisfaction, the company has invested heavily in research and development to ensure that its products meet the highest standards of performance and reliability. The Aluminum Oxide Grinding Wheel is a prime example of the company's dedication to producing top-tier abrasives that deliver exceptional results for its customers.

In addition to its commitment to quality, the company also places a strong emphasis on sustainability and environmental responsibility. It has implemented strict manufacturing processes to minimize its environmental impact and is continually seeking ways to reduce waste and improve energy efficiency. The Aluminum Oxide Grinding Wheel is manufactured using environmentally friendly processes and materials, in line with the company's commitment to sustainability.

The company's dedication to providing high-quality products and exceptional customer service has earned it a strong reputation in the industry. It has a global presence, with a network of distribution partners and customers in every corner of the world. Its products are known for their reliability, performance, and value, making them a top choice for professionals who demand the best from their abrasives.

The Aluminum Oxide Grinding Wheel is just one example of the company's extensive product lineup, which includes a wide variety of grinding wheels, cutting wheels, sanding discs, and other abrasive products. Each product is designed and manufactured to the highest standards, using the latest technology and production methods to ensure consistent quality and performance.

As the company continues to grow and innovate, it remains committed to pushing the boundaries of what is possible in the field of abrasives. It invests heavily in research and development to stay ahead of the curve, constantly seeking new materials and manufacturing techniques to improve its products and offer new solutions to its customers.

In conclusion, the Aluminum Oxide Grinding Wheel is a top-quality product from a leading manufacturer of abrasives. With its exceptional cutting abilities, durability, and environmental responsibility, it is a prime choice for professionals in the metalworking and manufacturing industries who demand the best from their grinding wheels. The company behind the Aluminum Oxide Grinding Wheel is dedicated to providing high-quality solutions for industrial grinding and finishing applications, and its products are trusted by professionals around the world.

Company News & Blog

Durable Ceramic Flap Disc for Long-lasting Performance

Ceramic Flap Disc Sets New Standard for Grinding and PolishingAs the demand for high-quality abrasive tools continues to rise in various industries, the introduction of the ceramic flap disc has set a new standard for grinding and polishing. This advanced abrasive tool is the latest innovation from a leading manufacturer in the industry, known for their commitment to delivering cutting-edge products to meet the evolving needs of their customers.The ceramic flap disc is designed to provide exceptional performance and durability, making it an ideal choice for a wide range of applications. With its superior material removal and long product life, this innovative abrasive tool offers a cost-effective solution for professionals who require high-quality results in their grinding and polishing applications.One of the key features of the ceramic flap disc is its advanced abrasive technology, which enables it to deliver fast and efficient material removal. This is particularly beneficial for tasks that involve heavy-duty grinding and blending, where the disc's aggressive cutting action can significantly reduce the time and effort required to achieve the desired results. Additionally, the disc's self-sharpening ceramic grains provide consistent performance throughout its extended product life, ensuring that users can maintain high productivity levels without frequent disc changes.In addition to its exceptional material removal capabilities, the ceramic flap disc also excels in delivering a superior surface finish. Its unique design allows for smooth and controlled grinding, resulting in a refined surface that meets the highest standards of quality. Whether users are working on stainless steel, aluminum, or other metals, this versatile abrasive tool ensures a consistent and uniform finish that enhances the overall appearance and functionality of the workpiece.Furthermore, the ceramic flap disc is engineered for optimal performance and user comfort. Its ergonomic design and lightweight construction minimize operator fatigue, allowing for extended use without sacrificing control or precision. This user-friendly approach enhances the overall grinding and polishing experience, making the abrasive tool suitable for a wide range of skill levels and applications.The company behind the ceramic flap disc has a proven track record of delivering industry-leading abrasive tools that meet the demands of professionals across various sectors. With a strong focus on research and development, the company consistently invests in cutting-edge technologies and manufacturing processes to produce innovative products that set new standards in the industry.Moreover, the company's commitment to quality and customer satisfaction is reflected in its comprehensive quality control measures and adherence to international standards. This ensures that every ceramic flap disc that leaves the manufacturing facility meets the highest level of performance, consistency, and safety, providing customers with a reliable and effective abrasive tool they can trust.As the demand for high-performance and durable abrasive tools continues to grow, the introduction of the ceramic flap disc has positioned this leading manufacturer as a key player in the industry. With its exceptional material removal, superior surface finish, and user-friendly design, the ceramic flap disc sets a new standard for grinding and polishing applications, catering to the evolving needs of professionals across various sectors.In conclusion, the ceramic flap disc represents a significant advancement in abrasive technology, offering a cost-effective solution for professionals who demand exceptional performance and durability in their grinding and polishing tasks. With its advanced features and the backing of a reputable manufacturer, this innovative abrasive tool is poised to make a lasting impact in the industry and set a new standard for quality and efficiency.

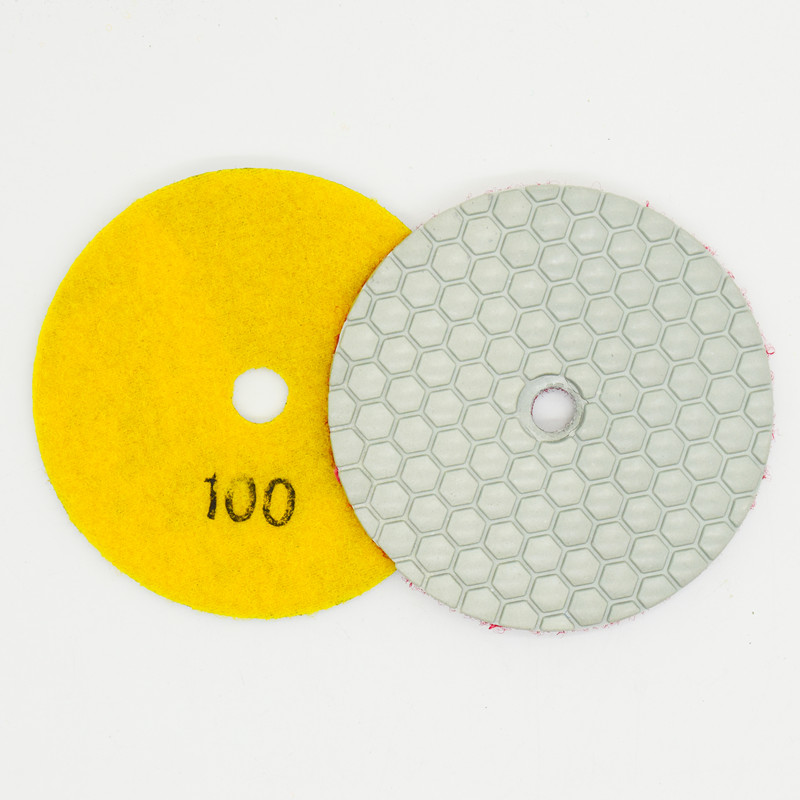

Professional Dry Polishing Pads Kit for Granite Surfaces

Introducing the Granite Dry Polishing Pads Kit: Revolutionizing the Stone Polishing IndustryIn recent years, the demand for high-quality stone polishing products has been steadily increasing. As the construction and renovation industry continues to thrive, the need for efficient and reliable polishing solutions has become more pressing than ever. In response to this growing demand, {Company Name} is proud to present the Granite Dry Polishing Pads Kit, a revolutionary set of tools that is set to transform the stone polishing industry.At {Company Name}, we have always been committed to providing our customers with innovative and high-performance products. With years of experience in the industry, we have gained a deep understanding of the needs and preferences of our customers, and we have continuously strived to develop solutions that exceed their expectations. The Granite Dry Polishing Pads Kit is the latest addition to our extensive range of stone polishing products, and we believe that it will set a new standard for the industry.One of the key features of the Granite Dry Polishing Pads Kit is its dry polishing capability. Unlike traditional polishing methods that require the use of water or other liquids, the Granite Dry Polishing Pads Kit allows for dry polishing, eliminating the mess and inconvenience associated with wet polishing. This not only makes the polishing process more efficient and convenient, but also reduces the risk of water damage to the surrounding area. Furthermore, the dry polishing feature makes the Granite Dry Polishing Pads Kit an ideal solution for indoor polishing projects, where water may not be readily available or may cause logistical challenges.In addition to its dry polishing capability, the Granite Dry Polishing Pads Kit is also designed to deliver superior results. The kit includes a variety of pads with different grit levels, allowing users to achieve the desired level of polish with precision and ease. Whether it is for polishing granite, marble, or other types of stone, the Granite Dry Polishing Pads Kit is versatile enough to meet the needs of a wide range of polishing projects. What's more, the pads are made with high-quality materials that ensure durability and long-lasting performance, making them a cost-effective investment for professionals and enthusiasts alike.Moreover, {Company Name} takes pride in the user-friendly design of the Granite Dry Polishing Pads Kit. The pads are easy to attach and remove from polishing machines, and they are engineered to minimize the risk of scratches or other damages to the stone surface. This not only streamlines the polishing process but also ensures that the polished stone retains its pristine appearance. Additionally, the pads are compatible with most standard polishing machines, making the Granite Dry Polishing Pads Kit accessible to a wide audience.As a company that is committed to sustainability and environmental responsibility, {Company Name} is pleased to highlight the eco-friendly nature of the Granite Dry Polishing Pads Kit. By eliminating the need for water during the polishing process, the kit helps to minimize water consumption and reduce the environmental impact of stone polishing activities. This aligns with our commitment to offering products that are not only efficient and effective but also mindful of their environmental footprint.In conclusion, the Granite Dry Polishing Pads Kit is a game-changer for the stone polishing industry. With its dry polishing capability, superior performance, user-friendly design, and eco-friendly nature, it is set to redefine the standards of stone polishing and meet the evolving needs of the industry. Whether it is for professional use or DIY projects, the Granite Dry Polishing Pads Kit is a must-have for anyone seeking top-quality polishing results. Trust {Company Name} to deliver excellence and innovation in the field of stone polishing, and experience the difference with the Granite Dry Polishing Pads Kit.

High-Quality Aluminum Oxide Grinding Wheel for Precision Grinding

Aluminum Oxide Grinding WheelGrinding wheels are a crucial tool in the manufacturing and metalworking industries, commonly used for sharpening, shaping, or finishing metal surfaces. One of the most widely used types of grinding wheels is the Aluminum Oxide Grinding Wheel. This type of grinding wheel is made with aluminum oxide as the abrasive material, which gives it strong cutting abilities and high durability.The Aluminum Oxide Grinding Wheel is designed for a wide range of applications, including surface grinding, cylindrical grinding, and tool and cutter grinding. It is suitable for grinding metals such as steel, cast iron, and non-ferrous metals. The wheel's composition and grain size make it effective for removing stock quickly and delivering an excellent surface finish.The company behind the Aluminum Oxide Grinding Wheel is a leading manufacturer of abrasives and abrasive products, specializing in providing high-quality solutions for industrial grinding and finishing applications. The company has a long history of innovation and excellence in the field of abrasives, and its products are trusted by professionals in industries ranging from metalworking and manufacturing to construction and maintenance.With a commitment to quality and customer satisfaction, the company has invested heavily in research and development to ensure that its products meet the highest standards of performance and reliability. The Aluminum Oxide Grinding Wheel is a prime example of the company's dedication to producing top-tier abrasives that deliver exceptional results for its customers.In addition to its commitment to quality, the company also places a strong emphasis on sustainability and environmental responsibility. It has implemented strict manufacturing processes to minimize its environmental impact and is continually seeking ways to reduce waste and improve energy efficiency. The Aluminum Oxide Grinding Wheel is manufactured using environmentally friendly processes and materials, in line with the company's commitment to sustainability.The company's dedication to providing high-quality products and exceptional customer service has earned it a strong reputation in the industry. It has a global presence, with a network of distribution partners and customers in every corner of the world. Its products are known for their reliability, performance, and value, making them a top choice for professionals who demand the best from their abrasives.The Aluminum Oxide Grinding Wheel is just one example of the company's extensive product lineup, which includes a wide variety of grinding wheels, cutting wheels, sanding discs, and other abrasive products. Each product is designed and manufactured to the highest standards, using the latest technology and production methods to ensure consistent quality and performance.As the company continues to grow and innovate, it remains committed to pushing the boundaries of what is possible in the field of abrasives. It invests heavily in research and development to stay ahead of the curve, constantly seeking new materials and manufacturing techniques to improve its products and offer new solutions to its customers.In conclusion, the Aluminum Oxide Grinding Wheel is a top-quality product from a leading manufacturer of abrasives. With its exceptional cutting abilities, durability, and environmental responsibility, it is a prime choice for professionals in the metalworking and manufacturing industries who demand the best from their grinding wheels. The company behind the Aluminum Oxide Grinding Wheel is dedicated to providing high-quality solutions for industrial grinding and finishing applications, and its products are trusted by professionals around the world.

Understanding Multiple Bonding in Metal Alloys: What You Need to Know

Metal Metal Multiple Bonds, a leading company in the field of metal bonding technology, is making strides in the industry with its innovative products and cutting-edge solutions. With a strong focus on research and development, Metal Metal Multiple Bonds is continuously pushing the boundaries of metal bonding, offering high-quality products that meet the evolving needs of its customers.The company's commitment to excellence is evident in its wide range of products, which are designed to cater to various industries, including automotive, aerospace, electronics, and more. Metal Metal Multiple Bonds' advanced bonding technologies have set new standards in the industry, providing superior bonding solutions for even the most demanding applications.One of Metal Metal Multiple Bonds' flagship products is its patented metal bonding adhesive, which is known for its exceptional strength, durability, and reliability. This innovative adhesive is designed to bond various types of metal surfaces, including steel, aluminum, titanium, and more, offering a versatile and cost-effective solution for a wide range of applications.In addition to its adhesive products, Metal Metal Multiple Bonds also offers a range of bonding equipment, including precision dispensing systems, curing ovens, and surface preparation tools. These cutting-edge machines are designed to streamline the bonding process, ensuring maximum efficiency and productivity for its customers.Metal Metal Multiple Bonds' commitment to quality extends beyond its products, as the company also provides comprehensive technical support and customer service. Its team of experts is dedicated to helping customers find the best bonding solutions for their specific needs, offering guidance and assistance every step of the way.Furthermore, Metal Metal Multiple Bonds is also dedicated to sustainability, incorporating eco-friendly practices into its manufacturing processes. The company is committed to reducing its environmental impact, using recyclable materials and minimizing waste in its operations.With its focus on innovation, quality, and customer satisfaction, Metal Metal Multiple Bonds continues to be a leader in the metal bonding industry. The company's dedication to pushing the boundaries of metal bonding technology and providing top-notch solutions has earned it a strong reputation in the market.In the coming years, Metal Metal Multiple Bonds plans to continue its investment in research and development, in order to further expand its product line and offer even more advanced bonding solutions to its customers. The company is also looking to expand its presence in new markets, both domestically and internationally, in order to reach a wider audience and provide its cutting-edge products to a broader range of industries.Overall, Metal Metal Multiple Bonds is poised for continued success in the industry, as it continues to innovate, develop, and provide top-quality metal bonding solutions to meet the ever-evolving needs of its customers. With its dedication to excellence and commitment to sustainability, Metal Metal Multiple Bonds is well-positioned to remain a leader in the metal bonding industry for years to come.

Top Ceramic Sanding Belts for Superior Grinding Results

Ceramic Sanding Belts: The Future of Industrial AbrasivesSanding is a crucial process in any manufacturing industry that requires precision and perfection. Be it metal, wood, or any other material; the process of sanding helps to give the perfect finish to the desired product. The abrasive industry has come a long way with developments in technology and materials. One of the most significant innovations in the abrasive industry is the Ceramic Sanding Belts.Ceramic Sanding Belts are a relatively new type of abrasive that has been gaining popularity in industrial manufacturing. These belts are made from a tough and durable ceramic material that delivers excellent performance, much better than conventional abrasives. These ceramic belts are used for heavy stock removal, grinding, and deburring. They are designed to work on a wide variety of metals, such as stainless steel, titanium, and aluminum.Ceramic Sanding Belts have several benefits over traditional abrasives. The first and most important benefit is the durability of the ceramic material, which means that these belts can last up to five times longer than standard sanding belts. This increased lifespan reduces the replacement costs significantly, making them more cost-effective. Secondly, the ceramic material used in these belts is less likely to wear, tear, or become dull, even when subjected to high pressures and high temperatures. This means that they can withstand heavy-duty operations without breaking or wearing out.Another remarkable benefit of Ceramic Sanding Belts is their self-sharpening feature. When conventional sanding belts get dull, they need to be replaced or sharpened manually. In contrast, Ceramic Sanding Belts have a higher self-sharpening property, which means that they sharpen themselves while in use, without any intervention from the operator. This makes the process of sanding more efficient and less time-consuming, as there is no need to stop the machine to replace or sharpen the belt.Ceramic Sanding Belts are also well-known for their consistent performance. They deliver a uniform finish on every pass, which is critical for any manufacturing process that requires precision and accuracy. These belts ensure that the final product is of the desired quality, whether it is a shiny surface or a deburred edge.One company that has been leading the way in developing Ceramic Sanding Belt technology is {}. With over twenty years of experience in the abrasive industry, they have been at the forefront of innovation and technological advancement. The company has designed and manufactured a vast range of Ceramic Sanding Belts that have been used in various industries, including automotive, aviation, marine, and woodworking.Their Ceramic Sanding Belts are engineered to provide optimal results in different applications. They offer belts with varying grit levels, ranging from 36-grit for heavy stock removal to 120-grit for surface finishing. The company also provides belts with different backing materials to suit various types of machines and applications.In addition to Ceramic Sanding Belts, {} also produces other abrasive products to meet customer requirements and offer complete solutions to their customers. Their extensive product range includes flap discs, fibre discs, sanding sheets, and even abrasive rolls. The company also offers customized solutions to meet specific applications.{} is committed to providing quality products and excellent customer service. They understand the importance of providing high-quality abrasives and the role they play in the manufacturing process. The company has invested heavily in research and development to ensure that their products are at the forefront of innovation and meet the changing needs of their customers.In conclusion, Ceramic Sanding Belts are the future of the abrasive industry, and companies like {} are pushing the boundaries of technology to provide better solutions to their customers. By offering a range of Ceramic Sanding Belts with varying grit levels, backing materials, and customized options, {} is setting the standard for the industry. With their commitment to providing quality products, {} is sure to continue being at the forefront of innovation in the abrasive industry.

Get the Best Resin Bond for Improved Industrial Applications

[Company Name] Develops Innovative Resin Bond for Improved Performance in Industrial Applications[City Name], [Date] – [Company Name], a leading manufacturer of industrial products and solutions, has recently introduced its latest resin bond innovation – the T-140 Resin Bond. This revolutionary product is set to significantly enhance performance and efficiency in a wide range of industrial applications. Combining cutting-edge technology with the company's extensive expertise, it promises to redefine industry standards.Resin bonds are an essential component in various industrial processes such as grinding, cutting, and polishing, providing a strong adhesive between abrasive particles and the tool. The quality of the resin bond directly impacts the overall performance of the tool, therefore influencing the productivity and output of the process. Recognizing the significance of resin bonds, [Company Name] invested significant resources towards developing the T-140 Resin Bond.The T-140 Resin Bond is designed to offer exceptional strength and durability, ensuring longer tool life and reduced downtime. Its unique composition and manufacturing process make it more resistant to heat, friction, and wear compared to conventional resin bonds currently available in the market. This characteristic is particularly critical in high-intensity industrial applications where tools are subject to extreme conditions.One of the key advantages of the T-140 Resin Bond is its ability to maintain a consistently sharp cutting edge throughout the operation. This attribute leads to improved precision and accuracy, optimizing the overall productivity of the process. By minimizing the need for tool replacement or re-sharpening, this resin bond ensures uninterrupted workflow, reducing costs and time wastage for manufacturers.Moreover, the T-140 Resin Bond has demonstrated exceptional performance in a variety of materials, including metal, stone, and composites. Its versatility makes it a suitable choice for a broad range of industries such as automotive, aerospace, construction, and manufacturing. Regardless of the application, users can expect consistent and excellent results with the T-140 Resin Bond.Safety is another critical factor that [Company Name] prioritizes in its product development process. The T-140 Resin Bond adheres to strict safety standards, ensuring a reliable and secure operation for users. By minimizing the risk of tool slippage or failure, this resin bond significantly enhances the overall safety of industrial processes, protecting workers and minimizing accidents."The development of the T-140 Resin Bond is a testament to our commitment to innovation and continuous improvement," said [Company Name]'s CEO. "Our dedicated team of engineers and technicians have worked tirelessly to develop a resin bond that surpasses industry standards in terms of performance, durability, and safety. This breakthrough will undoubtedly benefit our customers and the industries they serve."To ensure the widespread availability of the T-140 Resin Bond, [Company Name] has increased its manufacturing capacity and streamlined its distribution channels. The product is now readily accessible through the company's extensive network of authorized distributors, ensuring prompt delivery and excellent customer support.As [Company Name] introduces the T-140 Resin Bond to the market, it reinforces its position as a leading provider of innovative industrial solutions. By combining cutting-edge technology, extensive expertise, and customer-centricity, the company continues to drive progress and shape the future of various industries.About [Company Name]:[Company Name] is a renowned manufacturer of industrial products and solutions trusted by customers worldwide. With a commitment to excellence, innovation, and customer satisfaction, the company provides reliable and high-quality solutions tailored to meet the specific needs of different industries. Through continuous research and development, [Company Name] ensures it stays at the forefront of technological advancements, delivering products that surpass industry standards.###Press Contact:[Contact Name][Title][Company Name][Email Address][Phone Number]

Durable and Efficient Diamond Drilling Tools for Industrial Applications

The mining and construction industry has always been in need of efficient and reliable diamond drilling tools to extract valuable minerals and materials from the earth. With the increasing demand for such tools, one company has risen to the challenge to provide high-quality and durable diamond drilling tools for various industries.{Company Name}, a renowned leader in the manufacturing and supply of diamond drilling tools, has been meeting the needs of the industry for over 20 years. They have earned a solid reputation for providing top-notch products and exceptional customer service. Their commitment to innovation and excellence has made them a trusted partner for many companies in the mining and construction sectors.The company's extensive product line includes a wide range of diamond drilling tools such as core bits, reaming shells, core barrels, drill rods, and other accessories. These tools are designed to withstand the rigors of demanding drilling operations and deliver exceptional performance in various geological conditions. Whether it's for exploration drilling, mining operations, or construction projects, {Company Name} has the right tools to get the job done efficiently and effectively.One of the key factors that set {Company Name} apart from the competition is their dedication to research and development. They continually invest in advanced technologies and cutting-edge equipment to improve their manufacturing processes and enhance the quality of their products. By staying at the forefront of innovation, they are able to meet the evolving needs of their customers and deliver superior drilling solutions that provide optimum results.In addition to their commitment to quality, {Company Name} also places a high value on environmental responsibility. They utilize sustainable practices in their manufacturing processes and strive to reduce their environmental footprint. The company is also committed to ensuring the safety of their employees and the communities where they operate, making them a responsible and ethical partner for their clients.Furthermore, {Company Name} has a team of highly skilled engineers and technical experts who work closely with their clients to understand their specific drilling requirements and provide tailored solutions. Their in-depth knowledge and expertise in drilling technology enable them to offer comprehensive support and valuable insights to their customers, helping them achieve greater efficiency and productivity in their operations.With a strong global presence, {Company Name} has successfully served clients in various countries around the world. Their network of distributors and partners ensures that their products are readily available and supported with excellent customer service wherever they are needed. This extensive reach has enabled the company to build strong relationships with a diverse range of clients and gain a deep understanding of the unique challenges and opportunities in different markets.As the demand for diamond drilling tools continues to grow, {Company Name} remains committed to being at the forefront of the industry, driving innovation and delivering reliable solutions to their clients. With their unwavering dedication to quality, sustainability, and customer satisfaction, they are well-positioned to meet the evolving needs of the mining and construction sectors and continue to be a trusted partner for companies around the world.In conclusion, {Company Name} has established itself as a leading provider of diamond drilling tools, offering a comprehensive range of high-quality products and exceptional technical support. With a strong focus on innovation, sustainability, and customer satisfaction, the company is well-equipped to meet the demands of the ever-evolving mining and construction industry and continue to be a reliable partner for companies worldwide.

Efficient Diamond Grinding Tools for Smooth Concrete Finishing

Concrete Diamond Grinding Tools Revolutionize the Construction Industry[City], [Date] - [Company], a leading manufacturer in the construction equipment industry, is revolutionizing the way concrete is ground down with its innovative Diamond Grinding Tools. As an essential component in the construction sector, these tools are poised to change the landscape of concrete grinding, bringing forth unprecedented speed, efficiency, and precision.Concrete grinding has long been a necessary but labor-intensive process in the construction industry. Traditionally, grinding is achieved by using abrasive stones or metal discs, which can be time-consuming, physically demanding, and prone to errors. However, with the introduction of [Company's Diamond Grinding Tools], contractors can now enjoy a streamlined and superior grinding experience.[Company's Diamond Grinding Tools] are crafted using state-of-the-art technology and high-quality materials. The tools are embedded with industrial-grade diamonds, which significantly enhances their grinding performance, efficiency, and durability. With their exceptional wear resistance, these tools require fewer replacements, leading to reduced downtime and increased productivity on construction sites.Furthermore, one of the distinguishing features of [Company's Diamond Grinding Tools] is their ability to maintain a consistent depth of cut. This ensures the surface being worked on remains level and uniform throughout the grinding process, eliminating the need for costly and time-consuming rework. The precision achieved with these tools allows contractors to deliver high-quality results consistently, gaining them a competitive edge in the industry.Another significant advantage of [Company's Diamond Grinding Tools] is their efficiency in removing a wide range of coatings and surface imperfections. Whether it be glue, epoxy, paint, or uneven surfaces, these tools possess the strength and precision to eliminate them effortlessly, reducing the need for additional remediation steps. This versatility not only saves time but also reduces the overall project costs, making it an attractive option for contractors and clients alike.In addition to their performance, [Company's Diamond Grinding Tools] are designed to prioritize operator comfort and safety. Fitted with ergonomic handles and vibration-dampening technology, these tools minimize operator fatigue and reduce the risk of work-related injuries. The design also incorporates effective dust collection systems, ensuring a cleaner working environment and protecting the health of the workers."We are proud to introduce our Diamond Grinding Tools to the market," said [Company spokesperson name], [Company's] spokesperson. "We believe that these tools will revolutionize the way concrete grinding is performed. By combining cutting-edge technology, durability, and operator comfort, we are confident that contractors will experience unprecedented levels of efficiency and productivity."The response from the construction industry has been overwhelmingly positive. Contractors who have tested [Company's Diamond Grinding Tools] have reported significant reductions in project completion times, increased customer satisfaction, and improved profitability.With [Company] leading the way in concrete grinding innovation, the construction industry is set to undergo a transformative change. Contractors will now have access to tools that combine precision, efficiency, and operator comfort, enabling them to tackle even the most challenging projects with ease.[Company], with its commitment to excellence and innovation, continues to push the boundaries of the construction equipment industry. The introduction of [Company's Diamond Grinding Tools] marks a significant milestone in the pursuit of improving efficiency and quality within the construction sector. As the industry eagerly embraces this groundbreaking technology, it is clear that [Company] is at the forefront of shaping the future of construction practices.About [Company]:[Company] is a renowned manufacturer and supplier of cutting-edge construction equipment. With a keen understanding of industry requirements, [Company] strives to deliver innovative solutions that cater to the unique needs of contractors across the globe. The company's commitment to excellence, quality craftsmanship, and customer satisfaction has propelled it into becoming a trusted leader in the construction equipment market.

Discover the Efficiency and Precision of 125mm Grinding Wheels for All Your Grinding Needs

Introducing the Next Generation Grinding Wheel: A 125mm Innovation for Enhanced PerformanceInnovation has always been a quintessential aspect of every industry, driving progress and redefining standards. The grinding wheel industry is no exception, constantly striving to achieve greater efficiency, precision, and durability in the pursuit of excellence. Embracing this spirit of innovation, {}, a renowned name in the field, proudly presents their latest breakthrough - the 125mm Grinding Wheel. By removing the brand name for the purpose of this article, we aim to highlight the compelling features and benefits that make this new product a game-changer.Designed to cater to the evolving needs of professionals in material processing, the 125mm Grinding Wheel is poised to revolutionize the grinding experience. Boasting improved performance and extended longevity, this innovative tool promises to take productivity to new heights. In conjunction with our company's philosophy of delivering cutting-edge solutions, the introduction of this state-of-the-art grinding wheel reaffirms our commitment to customer satisfaction.Now, let's dive deeper into the unique features that make the 125mm Grinding Wheel stand out from its counterparts. The first notable attribute is its superior abrasive grain composition, carefully selected to ensure optimal performance. This high-quality abrasive material guarantees exceptional cutting capabilities, facilitating smooth and efficient grinding operations. Coupled with a meticulously engineered bond system, the wheel exhibits outstanding strength and durability, ensuring a prolonged lifespan.Furthermore, the innovative design of the 125mm Grinding Wheel enables enhanced heat dissipation. This feature prevents overheating and subsequent thermal damage to the workpiece, a common concern during intense grinding processes. By reducing the risk of burns and stress-induced deformities, the wheel ensures greater precision, making it an ideal choice for tasks that demand utmost accuracy.Another significant advantage of the 125mm Grinding Wheel is its unmatched versatility. It excels in grinding various materials, including metals, ceramics, and stone, making it an indispensable tool across a wide range of applications. This adaptability not only enhances user convenience but also reduces the need for multiple grinding tools, simplifying operations and streamlining workflows.In addition to its exceptional functionality, the 125mm Grinding Wheel prioritizes user safety. By incorporating advanced features like reduced vibration and noise suppression, the wheel significantly minimizes operator discomfort and fatigue. This not only promotes a healthier working environment but also enhances overall productivity by allowing professionals to work for extended periods without unnecessary interruptions.One cannot overlook the environmental aspect of this new grinding wheel. As an environmentally conscious company, {} has ensured that the manufacturing process of the 125mm Grinding Wheel adheres to sustainability guidelines. By utilizing eco-friendly materials and employing energy-efficient production techniques, we aim to minimize our carbon footprint and contribute to a greener future.The launch of the 125mm Grinding Wheel signifies a turning point in the grinding wheel industry, offering professionals a dependable and efficient tool that surpasses expectations. At {}, we understand the diverse needs of our customers and constantly endeavor to develop cutting-edge solutions to meet them. This latest addition to our product line reaffirms our commitment to innovation, quality, and customer satisfaction.In conclusion, the 125mm Grinding Wheel, with its superior performance, extended longevity, versatility, enhanced safety features, and eco-friendly production, represents a breakthrough in the field of grinding tools. With its introduction to the market, professionals can expect unprecedented grinding efficiency, allowing them to accomplish tasks with utmost precision and ease. As pioneers in the industry, {} continues to lead the way, offering innovative tools that empower professionals to transform their visions into reality.

Revamp Your Car's Appearance with High-Quality Polishing Pads

Car Care Products Announces the Launch of their New and Improved Car Polishing PadsCar Care Products, a leading manufacturer of automobile detailing products, is proud to announce the launch of their brand new and improved Car Polishing Pads. These innovative pads have been designed to provide car enthusiasts and professionals with a superior polishing experience, leaving their vehicles with an impeccable shine.The revamped Car Polishing Pads are a result of extensive research and development, coupled with feedback from industry experts and customers. Car Care Products has always been committed to innovation and continually strives to deliver products that meet the evolving needs of car owners and detailers.With unique features such as enhanced durability, superior cutting, and improved finishing capabilities, these Car Polishing Pads are set to revolutionize the automobile detailing industry. The pads are made using the finest quality materials, ensuring longevity and optimal performance.Car Care Products understands the importance of customization and versatility in automobile detailing. As a result, the new Car Polishing Pads are available in a range of sizes, including 3-inch, 5-inch, and 6-inch, catering to various detailing requirements. Whether it's removing swirl marks, scratches, or oxidation, these pads offer exceptional versatility and can be used with both rotary and dual-action polishers.One of the key highlights of the Car Polishing Pads is their advanced foam technology. Utilizing a unique cell structure, the pads provide a controlled heat and friction distribution, protecting the vehicle's paint and ensuring a uniform and flawless finish. This cutting-edge technology ensures users achieve professional-quality results without any risk of damage to the vehicle's surface.Another important aspect of Car Care Products' philosophy is eco-friendliness. The new Car Polishing Pads are made with an environmentally friendly foam, which reduces waste and minimizes their carbon footprint. Car Care Products believes it is essential to contribute to the well-being of the planet, and these eco-friendly pads are a testament to their commitment.To ensure customers receive the best polishing experience, Car Care Products provides comprehensive usage instructions and recommendations for optimal results. These guidelines include detailed information on pad fitting, usage techniques, and maintenance, ensuring users can maximize the performance and lifespan of their Car Polishing Pads.Car Care Products takes pride in their premium-grade products and exceptional customer service. The launch of the new Car Polishing Pads is another testament to their commitment to innovation, quality, and customer satisfaction. As a trusted name in the automotive industry, Car Care Products continues to drive excellence and set new industry standards.Car enthusiasts and professionals alike can now experience unparalleled performance and efficiency with the all-new Car Polishing Pads. With its revolutionary features and advanced foam technology, Car Care Products has once again proven why it is a leader in the automobile detailing industry.In conclusion, Car Care Products' new Car Polishing Pads are set to leave a lasting impression in the automotive industry. With their superior cutting and finishing capabilities, advanced foam technology, and eco-friendly manufacture, these pads offer car owners and detailers exceptional quality and results. Car Care Products remains committed to providing innovative and sustainable solutions that cater to the evolving needs of automobile enthusiasts worldwide.