High-quality 125mm Polishing Pads for Enhanced Surface Finishing

By:Admin

As a company dedicated to providing top-notch polishing solutions, {} has always been at the forefront of innovation in the industry. With a focus on quality and performance, they have consistently delivered products that exceed customer expectations. The introduction of the 125mm Polishing Pads is yet another testament to their commitment to excellence.

The 125mm Polishing Pads are designed to offer exceptional durability and cutting power, making them ideal for a variety of polishing tasks. Whether it's automotive, marine, or industrial applications, these pads are engineered to deliver superior results. They are also compatible with a wide range of polishing machines, making them versatile and easy to use.

One of the key features of the 125mm Polishing Pads is their advanced foam technology. The pads are constructed using high-quality foam materials that provide excellent cushioning and support during the polishing process. This not only ensures a smooth and even finish but also reduces the risk of swirl marks and other imperfections. Additionally, the foam composition also allows for efficient heat dissipation, preventing the pads from overheating during prolonged use.

Furthermore, the 125mm Polishing Pads are equipped with a unique hook and loop backing system, which ensures a secure and reliable attachment to the polishing machine. This allows for quick and easy pad changes, saving valuable time during the polishing process. The pads are also designed to be water-resistant, making them suitable for wet polishing applications without compromising their performance.

In addition to their impressive performance, the 125mm Polishing Pads are also designed with user convenience in mind. The pads are color-coded based on their level of abrasiveness, making it easy for users to select the right pad for their specific polishing needs. This simple yet effective system ensures that users can achieve the desired level of finish with ease.

With the introduction of the 125mm Polishing Pads, {} continues to set the standard for excellence in the polishing industry. Their relentless dedication to quality and innovation has made them a trusted name among professionals and enthusiasts alike. Whether it’s for automotive detailing, marine maintenance, or industrial polishing, customers can rely on {} to deliver exceptional results every time.

As a company, {} takes great pride in the quality and performance of their products. They are committed to providing customers with the best possible polishing solutions, and the 125mm Polishing Pads are a testament to that commitment. With their advanced design, superior durability, and user-friendly features, these pads are set to become the new benchmark for polishing excellence.

In conclusion, the introduction of the 125mm Polishing Pads by {} represents a significant step forward in the polishing industry. With their unparalleled performance and user-friendly design, these pads are poised to revolutionize the way professionals and enthusiasts approach polishing tasks. As {} continues to lead the way in innovation, customers can expect nothing but the best from their products.

Company News & Blog

Discover the Benefits of Surface Metal Bonds for Enhanced Performance

Surface Metal Bonds (SMB) is a leading company in the field of metal bonding solutions. With a wide range of products and services, SMB has established itself as a reliable and innovative partner for its customers. The company has a strong focus on research and development, constantly working to improve its products and develop new solutions for its clients. With a team of highly skilled professionals, SMB is able to provide custom-tailored solutions to meet the specific needs of each customer.One of SMB's flagship products is its patented metal bonding technology, which allows for the creation of strong and durable bonds between different types of metal surfaces. This technology has been widely acclaimed for its reliability and effectiveness, and has been used in a wide range of applications, from automotive and aerospace to electronics and telecommunications.SMB's metal bonding solutions have set a new industry standard, and the company continues to push the boundaries of what is possible in metal bonding technology. With a focus on innovation and customer satisfaction, SMB is constantly working to stay ahead of the competition and provide the best possible solutions to its clients.In addition to its cutting-edge technology, SMB also offers a range of value-added services to its customers. The company's team of experts is available to provide technical support and advice, helping customers to select the right products and implement them effectively. This level of support has earned SMB a reputation for excellence in customer service, and has helped to cement its position as a trusted partner for businesses around the world.SMB's commitment to quality and innovation has been recognized by industry leaders, and the company has received numerous awards and accolades for its products and services. These accolades are a testament to SMB's dedication to excellence, and serve as a reminder of the company's unwavering commitment to providing the best possible solutions to its customers.With a strong track record of success and a focus on continuous improvement, SMB is perfectly positioned to meet the evolving needs of its customers and the industry as a whole. The company's dedication to innovation and customer satisfaction has made it a leader in the field of metal bonding solutions, and SMB is poised to continue setting new standards for excellence in the years to come.In conclusion, Surface Metal Bonds is a company that has proven itself to be a leader in the field of metal bonding solutions. With a strong focus on innovation and customer satisfaction, SMB has set new industry standards and earned a reputation for excellence. As the company continues to push the boundaries of what is possible in metal bonding technology, SMB is well-positioned to meet the evolving needs of its customers and maintain its leadership position in the industry.

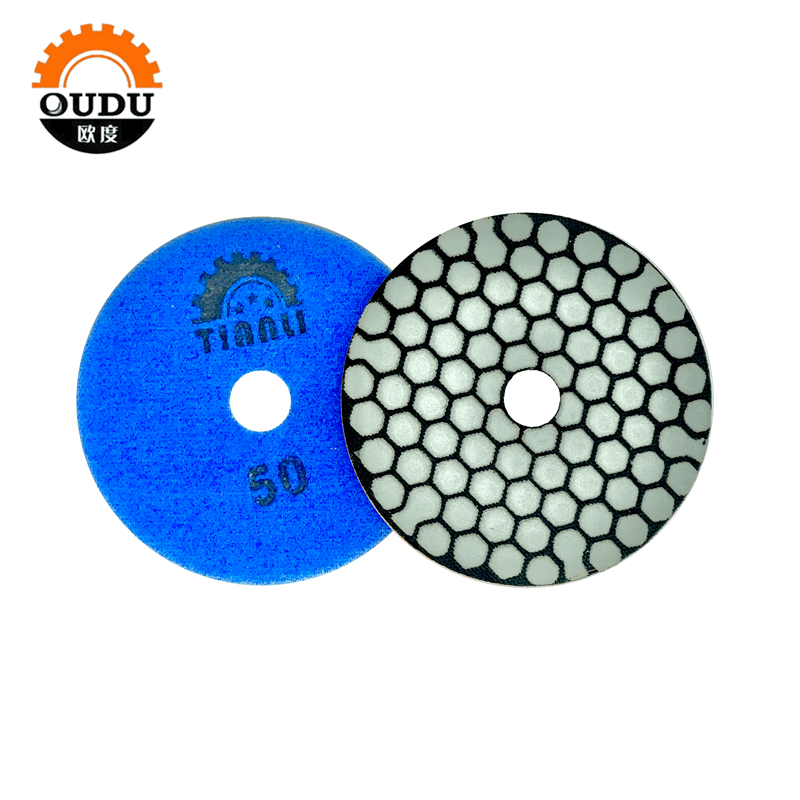

Discover the Benefits of a High-Quality Diamond Polishing Pad for Dry Surfaces

Introducing Dry Diamond Polishing Pad: A Revolutionary Innovation in the Polishing IndustryPolishing is an essential process used to enhance the appearance of various materials, ranging from natural stones like granite and marble to concrete and even glass. Over the years, polishing techniques have evolved, and today we are witnessing a revolutionary innovation in the form of Dry Diamond Polishing Pads, developed by a cutting-edge company. This groundbreaking product has taken the polishing industry by storm, offering unmatched efficiency, durability, and ease of use. Let's delve deeper into the features and benefits of this remarkable product.Dry Diamond Polishing Pad is a state-of-the-art solution for achieving a flawless finish on a variety of surfaces. Unlike traditional wet polishing pads that require water during the process, these pads are designed to work without the need for any additional liquid. This eliminates the mess and hassle associated with the use of water, making the entire polishing experience more convenient and efficient.The secret behind the exceptional performance of Dry Diamond Polishing Pads lies in their composition. These pads are embedded with high-quality diamond particles, known for their outstanding abrasive properties. The diamonds effectively remove imperfections, such as scratches, stains, and blemishes, while also providing a glossy, mirror-like finish. This unique composition ensures that the pads have a long lifespan, without losing their polishing power over time.Moreover, the company behind this innovative product has invested significant resources in research and development to ensure that their Dry Diamond Polishing Pads offer unparalleled performance. By leveraging advanced manufacturing techniques, the company has created pads that provide consistent results, avoiding any variation in the quality of the finish achieved.In addition to their remarkable efficiency, Dry Diamond Polishing Pads also offer remarkable durability. The diamond particles are firmly embedded in a resin matrix, ensuring that they don't detach or wear off easily. This outstanding durability means that polishing professionals can rely on these pads for extensive usage without the need for frequent replacements, ultimately saving time and money.The versatility of Dry Diamond Polishing Pads further contributes to their appeal. These pads work excellently with different surfaces, including but not limited to granite, marble, concrete, ceramic, and glass. Whether it's a residential kitchen countertop or a commercial flooring project, these pads are designed to handle various applications with exceptional results.Another significant advantage of Dry Diamond Polishing Pads is their user-friendly design. The pads come in various grit sizes, ranging from coarse to fine, allowing professionals to select the appropriate level of abrasiveness based on the specific requirements of the polishing project. The easy-to-use Velcro backing facilitates quick attachment and removal, minimizing downtime and maximizing productivity.As a result of these features and benefits, Dry Diamond Polishing Pads have quickly gained popularity among polishing professionals worldwide. Professionals especially appreciate the time saved by eliminating the need for water and the consistent and high-quality finish achieved. The revolutionary design of these pads has completely transformed the way the industry approaches polishing projects.In conclusion, the introduction of Dry Diamond Polishing Pads has brought about a paradigm shift in the polishing industry. This revolutionary product offers unmatched efficiency, durability, and ease of use, elevating the quality of polishing projects to new heights. With their innovative design and exceptional performance, these pads have become the go-to choice for professionals seeking flawless finishes on various surfaces. As the market demands higher standards, innovative products like Dry Diamond Polishing Pads will continue to revolutionize the industry, pushing the boundaries of what is possible in the world of polishing.

Nylon Brush for Angle Grinder - An In-Depth Look at Its Uses and Benefits

Industrial tools have been an integral part of the manufacturing and construction industry, and industrial brushes make up a significant part of this category. Many industries rely on brushes as they play a crucial role in finishing surfaces, cleaning machinery, and much more. One notable type of industrial brush is the nylon brush for an angle grinder. It is a highly specialized tool that is ideally suited for surface preparation and finishing works.An angle grinder is a powerful tool that is primarily used to cut, grind, and polish metal surfaces. However, adding a nylon brush to the angle grinder enhances its functionality, making it suitable for specialized purposes. The nylon brush is designed to access tight and hard-to-reach areas of metal surfaces that traditional sandpaper or wire brushes cannot reach. It is also effective in cleaning and deburring stainless steel, aluminum, and other delicate surfaces without scratching them.There are various types of nylon brushes for angle grinders, and the brush choice will depend on the material to be worked on, the finish required, and the angle grinder's speed and power capacity. For instance, the coarse mesh brush is ideal for removing rust, paint, and other stubborn stains from metal surfaces and grinding welded joints. On the other hand, the fine mesh brush provides a smooth finish on metal surfaces. It is suitable for tasks such as surface preparation before painting, polishing, or applying a protective coating.While it is essential to choose the right brush for your angle grinder, choosing a high-quality brand is equally important. One such brand is {Brand Name Removed}, a global leader in the production of industrial brushes. They have over 150 years of experience in the manufacturing of quality brushes, and their nylon brushes for angle grinders are no exception.Their nylon brushes for angle grinders are made from high-quality polyamide filaments that are durable, heat-resistant, and have excellent bending recovery properties. They have a wide range of brushes available for different types of jobs, including the coarse mesh brush, fine mesh brush, crimped wire brush, and many more. These brushes are easy to install and designed to fit most angle grinders, providing a quick and efficient cleaning or finishing solution.{Brand Name Removed} nylon brushes for angle grinders are also environmentally friendly. They are designed to last longer, reducing the need for frequent replacement, and are recyclable, reducing waste. This makes them an ideal choice for environmentally conscious industries.In conclusion, the nylon brush for an angle grinder is an essential tool for any industrial setting that requires surface finishing, preparation, or cleaning. When combined with high-quality brands such as {Brand Name Removed}, the nylon brush for angle grinders becomes a valuable asset in any work setting. Their durability, performance, and versatility make them an industry-standard in the manufacturing and construction sectors, where precision and quality matter most. With the right brush choice and the right brand, expect to work more efficiently and with greater precision.

Top Quality Hook and Loop Polishing Pads: A Comprehensive Guide

Hook And Loop Polishing Pads are making a significant impact in the automotive industry, providing an effective solution for polishing and buffing a wide range of surfaces. These pads are designed to be used with a variety of polishing machines, offering a versatile and efficient tool for car owners, professional detailers, and automotive manufacturers.The Hook And Loop Polishing Pads, also known as Velcro polishing pads, are making waves in the industry due to their innovative design and impressive performance. They are designed with a hook and loop attachment system that allows for quick and easy pad changes, saving time and effort during the polishing process. This feature makes them ideal for professionals who need to work quickly and efficiently, while also providing a user-friendly experience for car enthusiasts who want to achieve professional results at home. The pads are available in a range of sizes and shapes to accommodate different polishing machines and surface areas. Whether you are working on a small car panel or a large industrial surface, there is a pad suitable for the job. The range includes cutting pads for removing defects, polishing pads for refining the finish, and finishing pads for creating a high-gloss shine. This versatility makes them a valuable tool for anyone seeking to achieve a flawless finish on their vehicle or other surfaces.In addition to their impressive performance, the Hook And Loop Polishing Pads are also known for their durability and longevity. They are manufactured using high-quality materials that are designed to withstand the rigors of polishing and buffing. This means that they can be used repeatedly without deteriorating, providing excellent value for money over time. Their durable construction also ensures that they can handle the demands of professional use, making them a reliable choice for detailing businesses and automotive manufacturers alike.The company behind the Hook And Loop Polishing Pads, {}, is a leading manufacturer in the automotive industry, known for their commitment to quality and innovation. With years of experience in producing premium car care products, they have developed a strong reputation for delivering superior solutions that meet the needs of professionals and enthusiasts alike. Their dedication to research and development has resulted in a range of products that are at the forefront of the industry, including the popular Hook And Loop Polishing Pads.{} has invested considerable time and resources into the development of the Hook And Loop Polishing Pads, ensuring that they meet the highest standards of quality and performance. Their team of experts has worked tirelessly to create a product that delivers exceptional results, using the latest technology and manufacturing processes to achieve this goal. This commitment to excellence is evident in the overwhelmingly positive feedback from customers who have experienced the benefits of using the pads to achieve a flawless finish on their vehicles.The company's dedication to customer satisfaction is also reflected in their commitment to providing comprehensive support and guidance to all users of the Hook And Loop Polishing Pads. They offer detailed product information and usage instructions to ensure that customers can achieve the best results with their pads. Additionally, their customer service team is on hand to answer any queries and provide assistance where needed, further enhancing the overall experience of using their products.In conclusion, the Hook And Loop Polishing Pads from {} are a game-changer in the automotive industry, providing a versatile and efficient solution for achieving a flawless finish on a wide range of surfaces. With their innovative design, impressive performance, and durable construction, these pads are an invaluable tool for car owners, professional detailers, and automotive manufacturers. Backed by the expertise and dedication of {}, they represent a superior choice for anyone seeking to elevate their polishing and buffing capabilities.

New Study Shows Growing Demand for Metal Abrasives in Industrial Sector

Title: Metal Abrasives - Revolutionizing Manufacturing Through Cutting-Edge TechnologiesIntroduction: Metal Abrasives has emerged as a titan in the manufacturing industry, transforming the way professionals approach metalworking processes. With a commitment to innovation, quality, and sustainability, Metal Abrasives has earned its place as a global leader in metal abrasive solutions. Company Overview:Metal Abrasives, founded in 1990, is a privately-owned company headquartered in [Location]. With a dedicated team of experts, the company specializes in the production and distribution of a wide range of metal abrasives, catering to diverse industries such as automotive, aerospace, construction, and marine.The company's manufacturing facility is equipped with state-of-the-art technology, allowing Metal Abrasives to consistently deliver high-quality products that meet and exceed industry standards. Metal Abrasives takes pride in its commitment to sustainability, ensuring that its processes and products align with environmentally friendly practices.1. Pioneering Metal Abrasives:Metal Abrasives has continuously pushed the boundaries of metalworking technologies, offering cutting-edge solutions that enable professionals to achieve superior results. Through extensive research and development, the company has introduced several game-changing innovations to the market.a. SmartGrind: SmartGrind is Metal Abrasives' proprietary abrasive technology, utilizing advanced sensors and data analytics to optimize cutting and grinding processes. By monitoring parameters such as temperature, vibration, and pressure, SmartGrind ensures precision, efficiency, and enhanced control, reducing material waste and increasing productivity.b. NanoCoat:NanoCoat, a breakthrough surface treatment developed by Metal Abrasives, enhances the durability and performance of their metal abrasive products. This nanotechnology-based coating offers improved resistance to wear, reducing tool failure and extending overall product lifespan. NanoCoat also provides a smooth, consistent surface finish, facilitating better paint adhesion and coating uniformity.2. Commitment to Quality and Compliance:Metal Abrasives places utmost importance on maintaining the highest quality standards across all its products. The company adheres to international certifications and exceeds industry requirements, ensuring customer satisfaction and long-term reliability.a. ISO 9001:Metal Abrasives is proud to be ISO 9001 certified, signifying its commitment to quality management systems. This certification validates the company's dedication to meeting customer expectations through continual improvement and consistently delivering products that meet stringent quality benchmarks.b. Regulatory Compliance:Metal Abrasives strictly adheres to occupational health and safety regulations, minimizing operational risks and safeguarding the well-being of its workforce. Additionally, the company closely follows environmental standards, employing eco-friendly manufacturing processes and materials, thus reducing its carbon footprint and contributing to sustainability initiatives.3. Global Reach and Customer Support:With a vast network of distributors and partners worldwide, Metal Abrasives ensures its products reach customers across the globe. The company has established strong relationships with industry leaders, offering excellent customer support, technical assistance, and tailored solutions to meet specific requirements.Moreover, Metal Abrasives conducts regular training programs, workshops, and seminars for professionals, enabling them to optimize their metalworking processes, elevate their skills, and stay up-to-date with emerging trends in the industry.4. Future Expansion and Sustainability:Metal Abrasives remains committed to continuous growth and expansion. The company invests significantly in research and development to develop breakthrough technologies while keeping sustainability at the forefront of its operations.a. Recycling Initiatives:Metal Abrasives actively promotes recycling programs, encouraging the responsible disposal and utilization of used metal abrasives. By implementing a closed-loop system, the company reduces waste generation and raw material consumption, contributing to a greener future.b. Social Responsibility:Metal Abrasives believes in giving back to the community and actively supports philanthropic initiatives. Through partnerships with charitable organizations, the company contributes to education and healthcare programs, fostering positive social change.Conclusion:Metal Abrasives' relentless pursuit of innovation, commitment to quality, and dedication to sustainability have positioned the company as an industry forerunner. With groundbreaking technologies like SmartGrind and NanoCoat, Metal Abrasives enables professionals across sectors to elevate their metalworking processes, resulting in enhanced efficiency, reduced waste, and superior end products. As the company continues to expand its global reach, Metal Abrasives remains focused on shaping a sustainable future for the manufacturing industry.

Highly Efficient Wet Polisher for Granite Surfaces: Boost Your Polishing Projects!

As the construction industry continues to grow, the demand for high-quality stone fabrication and installation services also increases. Today, advanced firms use state-of-the-art equipment, such as the wet polisher, to promote a more efficient and precise stone polishing. One brand that stands out among these polishing machines is the Granite Wet Polisher.The Granite Wet Polisher is a powerful and cost-effective tool that transforms rough stone into a polished surface. It offers unparalleled benefits as it allows users to polish stones in a faster and more efficient way than traditional methods. With its excellent features, the Granite Wet Polisher has garnered positive reviews from its users, who attest to its exceptional performance and longevity.But beyond the machine's specifications, the story of Granite Wet Polisher's manufacturing process is just as fascinating.The company behind the Granite Wet Polisher prides itself on bringing together talented engineers and designers to create innovative and cutting-edge products. They use their collective experience in the industry to craft machines that give users improved performance and reliability.Apart from this dedication to quality, the company also ensures that their machines meet environmental standards. The Granite Wet Polisher is made with materials that are both durable and eco-friendly, making it one of the few machines that do not harm the environment.The company has also invested in state-of-the-art facilities to ensure that their products are manufactured efficiently. They regularly upgrade their production line to keep up with the competition, and their team of experts always strives to bring the latest technological innovations to their machines.As the construction industry moves towards digitization, the Granite Wet Polisher has become the go-to choice for stone fabrication businesses looking to improve their efficiency and quality of work. This is because the machine is easy to use, comes with useful features, and is compact enough to fit in any workshop.Aside from its technical specifications, the company's customer service is also top-notch. They understand that repair or maintenance work is a part of any machine's life, and that's why they offer a comprehensive warranty and repair service. Even if you're using an old Granite Wet Polisher, the company's team of technicians can diagnose and fix any issue.In conclusion, the Granite Wet Polisher is more than just a technical machine that performs a specific function. It represents the culmination of the company's dedication to quality, environment, and innovation. With the Granite Wet Polisher, stone fabrication businesses can increase their productivity, reduce costs, and improve the quality of their work.

Discover the Benefits of Using a 115mm Polishing Pad for a Flawless Finish

Title: Revolutionizing Polishing Technology: Introducing the 115mm Polishing PadIntroduction:In the ever-evolving world of polishing technology, one company stands out for its commitment to innovation and excellence. Revolutionizing the industry, this company has recently introduced the cutting-edge 115mm Polishing Pad, designed to deliver unrivaled performance and quality. By removing the brand name, let's delve into the features and benefits of this groundbreaking product, along with an overview of the company behind its creation.I. Unparalleled Performance:With a focus on meeting the diverse needs of professionals across various industries, the 115mm Polishing Pad showcases outstanding performance capabilities. Its key features include:1. Advanced Materials: Crafted using top-of-the-line materials, this polishing pad offers exceptional durability and longevity. Its robust construction ensures it can withstand the rigors of demanding polishing tasks.2. Optimal Dimensions: At 115mm, the pad strikes the perfect balance between usability and precision. Its compact size allows for effortless maneuverability, enabling users to reach tight corners and intricate surfaces with ease.3. Enhanced Polishing Efficiency: Equipped with a bespoke design and meticulous engineering, the 115mm Polishing Pad ensures remarkable efficiency. It maximizes application coverage and minimizes polishing time, resulting in a superior finish in less time.II. Outstanding Versatility:The versatility of the 115mm Polishing Pad makes it an indispensable tool for professionals across industries such as automotive, aerospace, and manufacturing. Its adaptability is attributed to the following factors:1. Wide Range of Applications: Whether it's restoring the shine of automotive paintwork, polishing delicate aircraft surfaces, or refining intricate machinery components, this pad caters to a variety of polishing needs.2. Compatibility with Diverse Materials: From metal to ceramics, the 115mm Polishing Pad is designed to work effectively on a wide range of materials. Its versatility ensures it can be utilized in numerous applications, opening up new possibilities for users.III. Innovators at the Helm:The company behind the groundbreaking 115mm Polishing Pad is a recognized leader in the field of polishing technology. With a sterling reputation for innovation and customer satisfaction, they have been at the forefront of developments in the industry. Key aspects of their identity include:1. Uncompromising Commitment to Quality: This company prides itself on maintaining the highest standards of quality. Each polishing pad undergoes rigorous testing to ensure it meets or exceeds customer expectations.2. Customer-Centric Approach: Recognizing that customer satisfaction is the cornerstone of success, this company places a premium on understanding and meeting the unique requirements of its clients. They constantly engage in research and development activities to stay ahead of market demands.3. Industry-Leading Expertise: Behind every product is a team of talented professionals with extensive knowledge and experience. The company's dedicated workforce comprises experts who continually strive to push the boundaries of polishing technology.Conclusion:The unveiling of the innovative 115mm Polishing Pad marks a significant development in the field of polishing technology. With its outstanding performance, versatility, and the backing of a reputable company, this product is set to revolutionize the industry. Professionals from various sectors can now utilize this cutting-edge pad to achieve remarkable results in their polishing applications. As the industry continues to embrace innovation, it is clear that this company's commitment to excellence and customer satisfaction will drive future advancements in polishing technology.

Sodium Metal Forms Bonds with Chloride in Breakthrough Study

Metal Sodium Bonds To Chloride: A Breakthrough in Chemical Bonding In a groundbreaking development in the field of chemistry, scientists at {} have made a significant discovery in the way metal sodium bonds to chloride. This discovery has the potential to revolutionize several industries, from pharmaceuticals to energy production.The traditional understanding of the bonding between metal sodium and chloride was that it was a purely ionic bond, meaning that the electron from the sodium atom is transferred to the chloride atom, resulting in the formation of a sodium cation and a chloride anion. However, the team at {} has found compelling evidence to suggest that the bonding between metal sodium and chloride is more complex than previously thought.Through a series of experiments using cutting-edge spectroscopic techniques, the researchers at {} have demonstrated that there is a significant covalent character to the bonding between metal sodium and chloride. This means that the electrons are shared between the sodium and chloride atoms, rather than being transferred completely from one to the other. This discovery challenges the conventional wisdom about the nature of the bonding in this fundamental chemical interaction.This breakthrough has significant implications for a wide range of industries. In the pharmaceutical sector, for example, the understanding of the bonding between metal sodium and chloride is crucial for the development of new drugs. By accurately understanding the nature of this bonding, researchers can better predict the behavior of new chemical compounds and tailor their properties to specific medical applications.In the energy sector, the discovery has the potential to improve the efficiency of batteries and other energy storage devices. A better understanding of the bonding between metal sodium and chloride can lead to the development of new materials that have higher energy densities and longer lifespans, making energy storage more efficient and cost-effective.The team at {} is already working on applying this new understanding of metal sodium-chloride bonding in practical applications. By leveraging their expertise in materials science and chemical engineering, they aim to develop new materials that take advantage of the covalent character of the bonding to create innovative products with enhanced properties and performance.This discovery is also a testament to the research capabilities of {}. With state-of-the-art laboratories and a team of world-class scientists and engineers, {} is at the forefront of scientific innovation. The company is committed to pushing the boundaries of knowledge and applying new discoveries to real-world problems, with the ultimate goal of improving the quality of life for people around the world.The implications of this discovery extend far beyond the immediate applications in pharmaceuticals and energy. In the field of fundamental chemistry, it challenges existing paradigms and opens up new avenues for exploration. By demonstrating the covalent character of metal sodium-chloride bonding, the researchers at {} have shed new light on a fundamental aspect of chemical reactivity, paving the way for further breakthroughs in the future.As the scientific community continues to explore the implications of this discovery, it is clear that the team at {} has made a significant contribution to our understanding of chemical bonding. This breakthrough has the potential to drive innovation across multiple industries and inspire new avenues of research, demonstrating the power of fundamental scientific discovery to shape the world we live in.

High-Quality 100mm Grinding Wheel for Precision Grinding Applications

The company, located in the heart of the manufacturing industry, is proud to announce the launch of their latest product - the 100mm Grinding Wheel. With their years of experience and dedication to providing high-quality tools and equipment, the company has once again proven themselves as leaders in the industry.The 100mm Grinding Wheel is designed to meet the demands of professionals and DIY enthusiasts alike. It is crafted to deliver exceptional performance and durability, making it an essential tool for any grinding and cutting tasks. Whether it's used for metalworking, construction, or automotive applications, this grinding wheel is guaranteed to deliver outstanding results.One of the key features of the 100mm Grinding Wheel is its versatility. It is capable of cutting and grinding various materials, including metal, steel, and stainless steel. This makes it a go-to tool for a wide range of tasks, from sharpening tools to removing rust and grinding welds.In addition to its versatility, the 100mm Grinding Wheel is also known for its exceptional durability. Crafted from high-quality materials, this grinding wheel is designed to withstand heavy-duty use and provide long-lasting performance. This means that professionals and enthusiasts can rely on it to get the job done, without having to worry about frequent replacements.Furthermore, the 100mm Grinding Wheel is designed for maximum precision and efficiency. Its carefully engineered design ensures smooth and precise cuts, while its high-performance capabilities allow for quick and efficient grinding. This not only saves time and effort, but also ensures precise and professional results every time.The company's dedication to quality and innovation is evident in the development of the 100mm Grinding Wheel. Their team of experts has put in countless hours of research and testing to ensure that this product meets the highest standards of excellence. As a result, customers can trust that they are investing in a reliable and high-performing tool.In addition to the 100mm Grinding Wheel, the company offers a wide range of products, including cutting wheels, grinding discs, and abrasive tools. Their commitment to providing top-notch tools and equipment has made them a trusted name in the industry. With a focus on quality, performance, and customer satisfaction, the company continues to set the bar high for their competitors.Customers can also rely on the company's exceptional customer service and support. Their team of professionals is dedicated to helping customers find the right tools for their needs and providing expert advice and guidance. This level of support is just another reason why the company has become a preferred choice for professionals and enthusiasts alike.The 100mm Grinding Wheel is now available for purchase, and customers can expect the same level of excellence that the company is known for. With its exceptional performance, durability, and precision, this grinding wheel is set to become a staple in workshops and job sites everywhere. Whether it's used for cutting, grinding, or sharpening, the 100mm Grinding Wheel is the ultimate tool for professionals and DIY enthusiasts.

Discover the Ultimate Grinding Wheels for Diamond and CBN Applications

Title: Industry-Leading Diamond CBN Grinding Wheels Revolutionary Solution for Superior PerformanceIntroduction: In today's fast-paced industrial landscape, the demand for high-performance grinding solutions has reached new heights. Leading the charge is a renowned company, specializing in developing and manufacturing advanced tools for all industries, including the groundbreaking Diamond CBN Grinding Wheels. Recognized for their innovative approach and dedication to delivering exceptional quality products, this company has revolutionized the grinding wheel industry.With an unwavering commitment to excellence and decades of experience, has become a trusted name in the manufacturing sector, setting the benchmark for precision and efficiency. The latest offering, their Diamond CBN Grinding Wheels, showcases their expertise and determination to deliver game-changing solutions that surpass customer expectations.Superior Manufacturing Process:The Diamond CBN Grinding Wheels offered by leverage the cutting-edge technology and expertise of the company. Through extensive research and development, they have achieved a manufacturing process that combines diamond and cubic boron nitride (CBN) to create a wheel that excels at grinding various materials.Diamond and CBN are two of the hardest known substances, offering extraordinary wear resistance. By utilizing these materials in their grinding wheels, ensures exceptional durability and extended operational lifespan. This unique combination enables these wheels to withstand high abrasion and heat generated during the grinding process, providing a reliable and consistent performance.Unmatched Versatility:One of the key attributes of the Diamond CBN Grinding Wheels is their unmatched versatility. Designed to excel across a wide range of grinding applications, these wheels are suitable for both wet and dry grinding processes. This flexibility allows various industries, including automotive, aerospace, and precision tool manufacturers, to benefit from the superior grinding capabilities provided by .Unrivalled Precision and Consistency:The precise manufacturing process employed by contributes to the diamond CBN grinding wheels' ability to achieve high-level accuracy and consistency. With their uniformity in grit distribution, these wheels offer precision grinding results, minimizing material wastage and enabling manufacturers to achieve tight tolerances in their products.Furthermore, due to the exceptional wear resistance properties of diamond and CBN, these wheels retain their shape and sharpness for longer periods, resulting in consistent grinding performance throughout their lifespan. This consistency ensures repeatable and reliable results for industries that demand the highest standards of quality and accuracy.Reduced Operational Costs:The innovative design of 's Diamond CBN Grinding Wheels benefits manufacturers in various ways, including cost reduction. These wheels' extended operational lifespan significantly reduces the frequency of wheel replacements, resulting in reduced downtime and increased productivity. Additionally, their exceptional material removal rates enable faster grinding, enhancing overall efficiency and reducing labor costs.Safety and Environmentally Conscious:In addition to their outstanding performance, the Diamond CBN Grinding Wheels prioritize safety and environmental considerations. The company adheres to strict quality control measures during the manufacturing process, ensuring that each wheel meets the highest safety standards. Additionally, these wheels generate fewer sparks during grinding, reducing the risk of workplace accidents, while minimizing the impact on the environment.Conclusion:Through the introduction of their Diamond CBN Grinding Wheels, has once again cemented their position as an industry leader, providing cutting-edge solutions to meet the evolving demands of various sectors. By harnessing the extraordinary attributes of diamond and CBN, has developed a product that offers unmatched grinding performance, exceptional durability, precision, versatility, and cost-effectiveness.As industries continue to strive for innovation and optimization, the Diamond CBN Grinding Wheels offered by remain at the forefront as a choice for manufacturers seeking superior grinding solutions. With their commitment to excellence and passion for engineering advancements, continues to pave the way for the future of grinding technology.