High-Quality 100mm Grinding Wheel for Precision Grinding

By:Admin

The 100mm grinding wheel is designed to remove material from a workpiece by rotating at high speeds and applying a significant amount of pressure. This allows for quick and precise grinding, making it an essential tool for various applications such as metalworking, woodworking, and maintenance of machinery and equipment.

With its advanced design and high-quality materials, the 100mm grinding wheel is able to deliver exceptional results with minimal effort. Its durable construction ensures that it can withstand the rigors of heavy-duty use, making it a long-lasting and reliable tool for any work environment.

One of the key features of the 100mm grinding wheel is its superior abrasive properties. The wheel is embedded with abrasive particles that are capable of grinding down even the toughest materials, making it highly versatile and suitable for a wide range of tasks.

In addition, the 100mm grinding wheel is designed for compatibility with a variety of grinders, making it a versatile and adaptable tool for any job. This ensures that users can easily integrate the wheel into their existing equipment and take advantage of its exceptional performance.

The company behind the 100mm grinding wheel is a renowned leader in the industrial machinery industry. With a strong reputation for quality and innovation, the company has been delivering cutting-edge solutions to professionals and hobbyists for years. Their commitment to excellence is evident in the design and performance of the 100mm grinding wheel, making it a standout product in their extensive lineup.

The company's dedication to customer satisfaction is another reason why the 100mm grinding wheel stands out in the market. They offer comprehensive support and guidance to users, ensuring that they are able to fully harness the capabilities of the wheel and achieve the best results for their applications.

Furthermore, the company is committed to sustainability and environmental responsibility. The manufacturing process of the 100mm grinding wheel adheres to strict environmental standards, ensuring that the product is both high-performing and eco-friendly.

Overall, the 100mm grinding wheel is a game-changing product that is set to revolutionize the way professionals and hobbyists approach grinding tasks. With its exceptional performance, durability, and versatility, it is sure to become an indispensable tool in any work environment. And with the backing of a reputable and innovative company, users can have confidence in the quality and reliability of this groundbreaking product.

Company News & Blog

Everything You Need to Know About Grinding Wheel Hubs

Grinding Wheel Hub Unveils Innovative Solutions for Manufacturing IndustryGrinding Wheel Hub, a leading manufacturer of cutting-edge grinding wheel solutions, is proud to introduce its latest innovations for the manufacturing industry. With a commitment to delivering high-quality products and exceptional customer service, Grinding Wheel Hub has become a trusted partner for companies across various sectors.Founded in [year], Grinding Wheel Hub has been at the forefront of developing innovative grinding wheel solutions that improve efficiency and productivity in the manufacturing process. The company's dedication to research and development has enabled it to create cutting-edge products that address the evolving needs of the industry.One of Grinding Wheel Hub's flagship products is its [product name], which has gained widespread recognition for its exceptional performance. The [product name] is designed to meet the demands of high-speed precision grinding, offering superior cutting ability and extended wheel life. With a focus on durability and consistency, this product has become a go-to choice for manufacturers looking to optimize their grinding operations.In addition to its advanced product line, Grinding Wheel Hub is also known for its customer-centric approach. The company works closely with clients to understand their specific requirements and develop customized solutions that meet their needs. Whether it's designing a new grinding wheel for a specialized application or providing technical support, Grinding Wheel Hub is committed to delivering value to its customers."We take pride in our ability to innovate and collaborate with our clients to create solutions that drive success in the manufacturing industry," said [Spokesperson Name], CEO of Grinding Wheel Hub. "Our focus on quality, reliability, and performance has positioned us as a trusted partner for companies seeking cutting-edge grinding wheel solutions."Beyond its products and services, Grinding Wheel Hub is also dedicated to sustainability and environmental stewardship. The company has implemented various initiatives to reduce waste and minimize its carbon footprint, aligning with the growing emphasis on sustainable manufacturing practices.As part of its ongoing commitment to innovation, Grinding Wheel Hub continues to invest in research and development to stay ahead of industry trends. The company's state-of-the-art manufacturing facilities and testing laboratories enable it to uphold the highest standards of quality and performance.With an unwavering dedication to excellence, Grinding Wheel Hub has earned a strong reputation in the manufacturing industry. The company's ability to provide reliable, cutting-edge solutions has established it as a leader in the market, catering to diverse needs across various sectors.Looking ahead, Grinding Wheel Hub is poised to further expand its product line and capabilities to meet the evolving needs of the manufacturing industry. The company's commitment to innovation, quality, and customer satisfaction sets the stage for continued success and leadership in the market.As the manufacturing industry continues to evolve, Grinding Wheel Hub remains at the forefront, empowering companies with advanced grinding wheel solutions that drive efficiency, productivity, and success. With its unwavering commitment to excellence, the company is well-positioned to shape the future of manufacturing with its innovative products and customer-centric approach.

Durable and Efficient Diamond Drilling Tools for Industrial Applications

The mining and construction industry has always been in need of efficient and reliable diamond drilling tools to extract valuable minerals and materials from the earth. With the increasing demand for such tools, one company has risen to the challenge to provide high-quality and durable diamond drilling tools for various industries.{Company Name}, a renowned leader in the manufacturing and supply of diamond drilling tools, has been meeting the needs of the industry for over 20 years. They have earned a solid reputation for providing top-notch products and exceptional customer service. Their commitment to innovation and excellence has made them a trusted partner for many companies in the mining and construction sectors.The company's extensive product line includes a wide range of diamond drilling tools such as core bits, reaming shells, core barrels, drill rods, and other accessories. These tools are designed to withstand the rigors of demanding drilling operations and deliver exceptional performance in various geological conditions. Whether it's for exploration drilling, mining operations, or construction projects, {Company Name} has the right tools to get the job done efficiently and effectively.One of the key factors that set {Company Name} apart from the competition is their dedication to research and development. They continually invest in advanced technologies and cutting-edge equipment to improve their manufacturing processes and enhance the quality of their products. By staying at the forefront of innovation, they are able to meet the evolving needs of their customers and deliver superior drilling solutions that provide optimum results.In addition to their commitment to quality, {Company Name} also places a high value on environmental responsibility. They utilize sustainable practices in their manufacturing processes and strive to reduce their environmental footprint. The company is also committed to ensuring the safety of their employees and the communities where they operate, making them a responsible and ethical partner for their clients.Furthermore, {Company Name} has a team of highly skilled engineers and technical experts who work closely with their clients to understand their specific drilling requirements and provide tailored solutions. Their in-depth knowledge and expertise in drilling technology enable them to offer comprehensive support and valuable insights to their customers, helping them achieve greater efficiency and productivity in their operations.With a strong global presence, {Company Name} has successfully served clients in various countries around the world. Their network of distributors and partners ensures that their products are readily available and supported with excellent customer service wherever they are needed. This extensive reach has enabled the company to build strong relationships with a diverse range of clients and gain a deep understanding of the unique challenges and opportunities in different markets.As the demand for diamond drilling tools continues to grow, {Company Name} remains committed to being at the forefront of the industry, driving innovation and delivering reliable solutions to their clients. With their unwavering dedication to quality, sustainability, and customer satisfaction, they are well-positioned to meet the evolving needs of the mining and construction sectors and continue to be a trusted partner for companies around the world.In conclusion, {Company Name} has established itself as a leading provider of diamond drilling tools, offering a comprehensive range of high-quality products and exceptional technical support. With a strong focus on innovation, sustainability, and customer satisfaction, the company is well-equipped to meet the demands of the ever-evolving mining and construction industry and continue to be a reliable partner for companies worldwide.

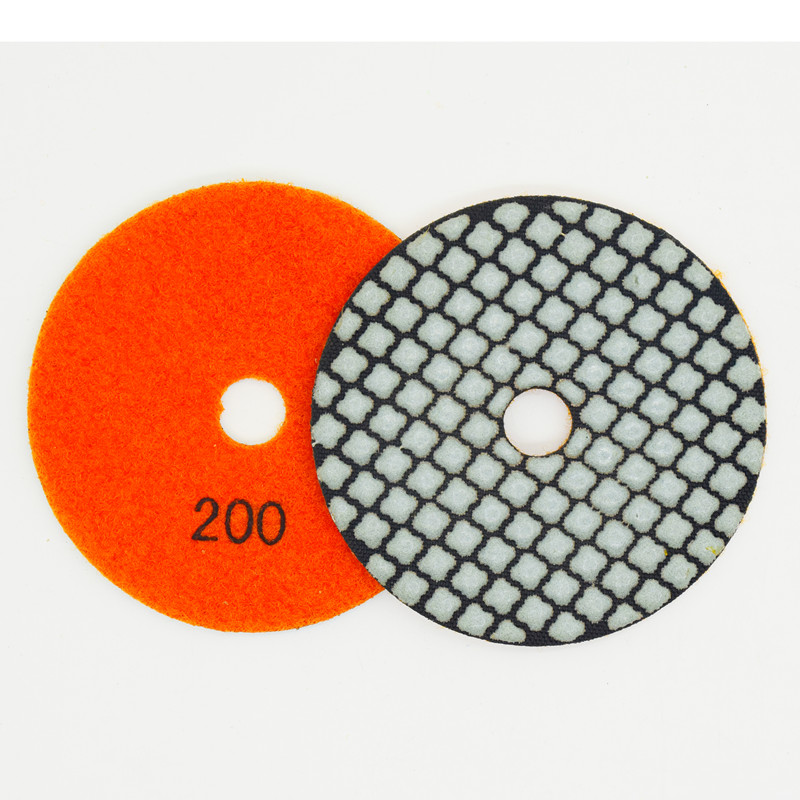

Discover the Benefits of Using a 115mm Polishing Pad for a Flawless Finish

Title: Revolutionizing Polishing Technology: Introducing the 115mm Polishing PadIntroduction:In the ever-evolving world of polishing technology, one company stands out for its commitment to innovation and excellence. Revolutionizing the industry, this company has recently introduced the cutting-edge 115mm Polishing Pad, designed to deliver unrivaled performance and quality. By removing the brand name, let's delve into the features and benefits of this groundbreaking product, along with an overview of the company behind its creation.I. Unparalleled Performance:With a focus on meeting the diverse needs of professionals across various industries, the 115mm Polishing Pad showcases outstanding performance capabilities. Its key features include:1. Advanced Materials: Crafted using top-of-the-line materials, this polishing pad offers exceptional durability and longevity. Its robust construction ensures it can withstand the rigors of demanding polishing tasks.2. Optimal Dimensions: At 115mm, the pad strikes the perfect balance between usability and precision. Its compact size allows for effortless maneuverability, enabling users to reach tight corners and intricate surfaces with ease.3. Enhanced Polishing Efficiency: Equipped with a bespoke design and meticulous engineering, the 115mm Polishing Pad ensures remarkable efficiency. It maximizes application coverage and minimizes polishing time, resulting in a superior finish in less time.II. Outstanding Versatility:The versatility of the 115mm Polishing Pad makes it an indispensable tool for professionals across industries such as automotive, aerospace, and manufacturing. Its adaptability is attributed to the following factors:1. Wide Range of Applications: Whether it's restoring the shine of automotive paintwork, polishing delicate aircraft surfaces, or refining intricate machinery components, this pad caters to a variety of polishing needs.2. Compatibility with Diverse Materials: From metal to ceramics, the 115mm Polishing Pad is designed to work effectively on a wide range of materials. Its versatility ensures it can be utilized in numerous applications, opening up new possibilities for users.III. Innovators at the Helm:The company behind the groundbreaking 115mm Polishing Pad is a recognized leader in the field of polishing technology. With a sterling reputation for innovation and customer satisfaction, they have been at the forefront of developments in the industry. Key aspects of their identity include:1. Uncompromising Commitment to Quality: This company prides itself on maintaining the highest standards of quality. Each polishing pad undergoes rigorous testing to ensure it meets or exceeds customer expectations.2. Customer-Centric Approach: Recognizing that customer satisfaction is the cornerstone of success, this company places a premium on understanding and meeting the unique requirements of its clients. They constantly engage in research and development activities to stay ahead of market demands.3. Industry-Leading Expertise: Behind every product is a team of talented professionals with extensive knowledge and experience. The company's dedicated workforce comprises experts who continually strive to push the boundaries of polishing technology.Conclusion:The unveiling of the innovative 115mm Polishing Pad marks a significant development in the field of polishing technology. With its outstanding performance, versatility, and the backing of a reputable company, this product is set to revolutionize the industry. Professionals from various sectors can now utilize this cutting-edge pad to achieve remarkable results in their polishing applications. As the industry continues to embrace innovation, it is clear that this company's commitment to excellence and customer satisfaction will drive future advancements in polishing technology.

Nylon Brush for Angle Grinder - An In-Depth Look at Its Uses and Benefits

Industrial tools have been an integral part of the manufacturing and construction industry, and industrial brushes make up a significant part of this category. Many industries rely on brushes as they play a crucial role in finishing surfaces, cleaning machinery, and much more. One notable type of industrial brush is the nylon brush for an angle grinder. It is a highly specialized tool that is ideally suited for surface preparation and finishing works.An angle grinder is a powerful tool that is primarily used to cut, grind, and polish metal surfaces. However, adding a nylon brush to the angle grinder enhances its functionality, making it suitable for specialized purposes. The nylon brush is designed to access tight and hard-to-reach areas of metal surfaces that traditional sandpaper or wire brushes cannot reach. It is also effective in cleaning and deburring stainless steel, aluminum, and other delicate surfaces without scratching them.There are various types of nylon brushes for angle grinders, and the brush choice will depend on the material to be worked on, the finish required, and the angle grinder's speed and power capacity. For instance, the coarse mesh brush is ideal for removing rust, paint, and other stubborn stains from metal surfaces and grinding welded joints. On the other hand, the fine mesh brush provides a smooth finish on metal surfaces. It is suitable for tasks such as surface preparation before painting, polishing, or applying a protective coating.While it is essential to choose the right brush for your angle grinder, choosing a high-quality brand is equally important. One such brand is {Brand Name Removed}, a global leader in the production of industrial brushes. They have over 150 years of experience in the manufacturing of quality brushes, and their nylon brushes for angle grinders are no exception.Their nylon brushes for angle grinders are made from high-quality polyamide filaments that are durable, heat-resistant, and have excellent bending recovery properties. They have a wide range of brushes available for different types of jobs, including the coarse mesh brush, fine mesh brush, crimped wire brush, and many more. These brushes are easy to install and designed to fit most angle grinders, providing a quick and efficient cleaning or finishing solution.{Brand Name Removed} nylon brushes for angle grinders are also environmentally friendly. They are designed to last longer, reducing the need for frequent replacement, and are recyclable, reducing waste. This makes them an ideal choice for environmentally conscious industries.In conclusion, the nylon brush for an angle grinder is an essential tool for any industrial setting that requires surface finishing, preparation, or cleaning. When combined with high-quality brands such as {Brand Name Removed}, the nylon brush for angle grinders becomes a valuable asset in any work setting. Their durability, performance, and versatility make them an industry-standard in the manufacturing and construction sectors, where precision and quality matter most. With the right brush choice and the right brand, expect to work more efficiently and with greater precision.

Efficient Polishing Tools Boosting Your SEO Performance for Optimal Results

article as below:Polishing Tools: A Step Ahead in Metalworking IndustryPolishing tools play a crucial role in the metalworking industry. They are used to remove any unwanted material from the surface of metalworkpieces to provide them with a smooth and shiny finish. Polishing tools are also used to improve the surface quality of metal workpieces, making them more durable and appealing. One company leading the way in the development of advanced polishing tools is based in the United States.This company (we will refer to it as the company throughout the article) was established with the objective of providing state-of-the-art polishing tools that are efficient, durable and easy to use. Since its inception, the company has remained true to its mission by consistently producing top-quality polishing tools used widely in the metalworking industry.The company's range of polishing tools includes grinding wheels, abrasive belts, and flap discs. These polishing tools are designed to meet the varying needs of different types of metal workpieces and different surface finishes. The tools are used in different parts of the process, including smoothing, grinding, polishing and finishing.One of the key features of the company's polishing tools is their durability. The tools are made from high-quality materials that are engineered to withstand heavy usage and provide long-lasting performance. This is a major advantage for metalworking companies that depend on the efficiency of their equipment to meet their production targets. The durability of the tools ensures minimal downtime, reduced maintenance cost, and maximum productivity.Another important aspect of the company's polishing tools is their ease of use. The tools are designed to be user-friendly, allowing workers to operate them efficiently without any difficulty. This is particularly important for metalworking companies that employ a large number of workers. With easy-to-use tools, companies can ensure that workers can produce the desired results with minimal supervision.The company has invested heavily in research and development to ensure that its polishing tools remain ahead of the competition. Through its state-of-the-art research facilities, the company has developed several innovative polishing tools that have further improved efficiency and productivity in the metalworking industry.One of the company's recent developments is a range of environmentally friendly polishing tools. The company recognizes the need for companies to prioritize environmental sustainability in their operations. Consequently, it has developed polishing tools that do not pose any harm to the environment. These tools are made from sustainable materials and are designed to reduce the need for excessive polishing, consequently reducing waste.The company also understands the importance of providing excellent customer service. It employs a team of experienced and knowledgeable professionals who are always ready to assist customers with any queries or issues they may encounter with the tools. This has earned the company a reputation for providing reliable and effective customer support.The company's commitment to excellence has also seen it forge partnerships with other industry players. These partnerships have enabled the company to gain access to cutting-edge production technology and industry expertise that have further enhanced the quality of its polishing tools.In conclusion, polishing tools are an essential element of the metalworking industry. They are used to provide metal workpieces with a smooth and shiny finish, which enhances their durability and appeal. The company is at the forefront of the development of top-quality polishing tools that are efficient, durable, and easy to use. With its commitment to research and development, excellent customer service, and partnerships, the company is poised to remain a leading player in the metalworking industry for years to come.

Revitalizing Your Vehicle's Shine: A Comprehensive Guide to Automotive Polishing Pads

Automotive Polishing Pads Revolutionize Car Care with Innovative Technology[Company Name]: Revolutionizing Car Care with Cutting-edge Automotive Polishing Pads[date]Car enthusiasts and detailers alike are rejoicing as [Company Name] unveils their groundbreaking line of Automotive Polishing Pads. These state-of-the-art products have been meticulously designed and developed to enhance the car care experience, making it easier and more efficient for individuals to achieve a flawless finish on their vehicles.Introducing a new era of car care, [Company Name] has spent years perfecting their Automotive Polishing Pads, combining innovative designs and advanced materials to create a revolution in car detailing. With a commitment to quality and customer satisfaction, this company has gained a reputation for delivering unparalleled performance and industry-leading results.[Company Name] believes that the key to a perfect finish lies in the details. Recognizing this, their team of experts has developed an extensive range of polishing pads that caters to every car care need. These pads are specially formulated to deliver exceptional results on various surfaces, including paintwork, glass, and metal. Whether it is removing scratches and swirl marks or restoring the shine and luster of a vehicle, [Company Name]'s Automotive Polishing Pads guarantee outstanding performance.One of the key features that sets [Company Name]'s Automotive Polishing Pads apart from its competitors is the utilization of advanced foam technologies. The company has employed cutting-edge research and development techniques to create specialized foam formulations that optimize the polishing process. These foams are engineered to deliver the perfect balance of cutting and finishing capabilities, ensuring precise and efficient results every time.Additionally, [Company Name] has integrated an innovative, proprietary hook and loop system into their polishing pads. This unique system allows for quick and easy pad changes, saving valuable time and effort for users. The pads securely attach to backing plates, ensuring stability and reducing the risk of pad slippage during the polishing process.One of the standout features of [Company Name]'s Automotive Polishing Pads is their durability. These pads are designed to withstand extended use and provide consistent performance, making them a cost-effective choice for both professionals and hobbyists alike. The company's commitment to durability goes hand in hand with their dedication to environmental sustainability, as they strive to minimize waste and promote eco-friendly practices throughout their manufacturing process.Furthermore, [Company Name] ensures that their Automotive Polishing Pads are suitable for use with various polishing machines, accommodating the needs of different users. The pads' versatility allows customers to achieve professional-level results regardless of their skill level or experience in car detailing.With the release of their Automotive Polishing Pads, [Company Name] cements its position as an industry leader in the car care market. Their dedication to innovation, exceptional performance, and customer satisfaction is evident in each pad they produce. As a company that prides itself on continuous improvement, [Company Name] is already working towards future developments, aiming to further advance car care technologies and solutions.Whether you are a professional detailer or an avid car enthusiast, [Company Name]'s Automotive Polishing Pads are set to revolutionize the way we care for our vehicles. With their state-of-the-art technology, customizable options, and unparalleled performance, achieving a flawless finish has never been easier. Experience the difference and take your car care routine to new heights with [Company Name]'s Automotive Polishing Pads.About [Company Name]:[Company Name] is a leading provider of innovative car care solutions, dedicated to delivering exceptional performance and superior results. With a focus on continuous improvement and cutting-edge technologies, the company continually pushes the boundaries of what is possible in the car care industry. Their commitment to quality, durability, and customer satisfaction sets [Company Name] apart as an industry pioneer.

Top Ceramic Sanding Belts for Superior Grinding Results

Ceramic Sanding Belts: The Future of Industrial AbrasivesSanding is a crucial process in any manufacturing industry that requires precision and perfection. Be it metal, wood, or any other material; the process of sanding helps to give the perfect finish to the desired product. The abrasive industry has come a long way with developments in technology and materials. One of the most significant innovations in the abrasive industry is the Ceramic Sanding Belts.Ceramic Sanding Belts are a relatively new type of abrasive that has been gaining popularity in industrial manufacturing. These belts are made from a tough and durable ceramic material that delivers excellent performance, much better than conventional abrasives. These ceramic belts are used for heavy stock removal, grinding, and deburring. They are designed to work on a wide variety of metals, such as stainless steel, titanium, and aluminum.Ceramic Sanding Belts have several benefits over traditional abrasives. The first and most important benefit is the durability of the ceramic material, which means that these belts can last up to five times longer than standard sanding belts. This increased lifespan reduces the replacement costs significantly, making them more cost-effective. Secondly, the ceramic material used in these belts is less likely to wear, tear, or become dull, even when subjected to high pressures and high temperatures. This means that they can withstand heavy-duty operations without breaking or wearing out.Another remarkable benefit of Ceramic Sanding Belts is their self-sharpening feature. When conventional sanding belts get dull, they need to be replaced or sharpened manually. In contrast, Ceramic Sanding Belts have a higher self-sharpening property, which means that they sharpen themselves while in use, without any intervention from the operator. This makes the process of sanding more efficient and less time-consuming, as there is no need to stop the machine to replace or sharpen the belt.Ceramic Sanding Belts are also well-known for their consistent performance. They deliver a uniform finish on every pass, which is critical for any manufacturing process that requires precision and accuracy. These belts ensure that the final product is of the desired quality, whether it is a shiny surface or a deburred edge.One company that has been leading the way in developing Ceramic Sanding Belt technology is {}. With over twenty years of experience in the abrasive industry, they have been at the forefront of innovation and technological advancement. The company has designed and manufactured a vast range of Ceramic Sanding Belts that have been used in various industries, including automotive, aviation, marine, and woodworking.Their Ceramic Sanding Belts are engineered to provide optimal results in different applications. They offer belts with varying grit levels, ranging from 36-grit for heavy stock removal to 120-grit for surface finishing. The company also provides belts with different backing materials to suit various types of machines and applications.In addition to Ceramic Sanding Belts, {} also produces other abrasive products to meet customer requirements and offer complete solutions to their customers. Their extensive product range includes flap discs, fibre discs, sanding sheets, and even abrasive rolls. The company also offers customized solutions to meet specific applications.{} is committed to providing quality products and excellent customer service. They understand the importance of providing high-quality abrasives and the role they play in the manufacturing process. The company has invested heavily in research and development to ensure that their products are at the forefront of innovation and meet the changing needs of their customers.In conclusion, Ceramic Sanding Belts are the future of the abrasive industry, and companies like {} are pushing the boundaries of technology to provide better solutions to their customers. By offering a range of Ceramic Sanding Belts with varying grit levels, backing materials, and customized options, {} is setting the standard for the industry. With their commitment to providing quality products, {} is sure to continue being at the forefront of innovation in the abrasive industry.

Discover the Benefits of Wire Brush Grinding Wheels

Title: Industry Leader Introduces Innovative Wire Brush Grinding Wheel to Enhance Metal Surface PreparationIntroduction:[Company Name], a renowned industry leader in manufacturing high-quality metalworking tools and equipment, is proud to announce the launch of their latest product innovation — the Wire Brush Grinding Wheel. Designed to revolutionize metal surface preparation, this cutting-edge tool offers exceptional performance, durability, and efficiency, catering to professionals across various industries.Blending state-of-the-art technology with years of expertise, [Company Name] has successfully developed a Wire Brush Grinding Wheel that surpasses existing market offerings in terms of quality and functionality. This innovative tool is set to enable professionals to achieve precise and effective metal surface preparation, ensuring excellent results in a wide range of applications such as welding, painting, and coating.Product Features:The Wire Brush Grinding Wheel features a unique combination of high-grade wire bristles and an advanced grinding wheel. The wire bristles are skillfully designed and evenly spaced, ensuring efficient removal of rust, scale, and other contaminants from metal surfaces. The grinding wheel, made of premium abrasives, ensures smooth and precise grinding, resulting in a flawless surface ready for subsequent processes.Moreover, the Wire Brush Grinding Wheel incorporates an ergonomic design that allows for comfortable and safe handling during extended periods of use. The tool's lightweight construction reduces operator fatigue and increases overall productivity.Industry-leading professionals who have tested the Wire Brush Grinding Wheel express their satisfaction with its superior performance and durability. Unlike traditional abrasive wheels that wear out quickly, this innovative tool maintains its grinding power and wire bristle efficiency over extended periods, reducing downtime and enabling longer operational life.Applications:The Wire Brush Grinding Wheel caters to diverse industries, including manufacturing, construction, automotive, and metal fabrication. Professionals engaged in surface preparation, metal cleaning, and restoration processes can benefit greatly from this tool's exceptional capabilities.In metal manufacturing, the Wire Brush Grinding Wheel proves invaluable in surface conditioning, deburring, and weld seam cleaning. It easily removes rust, paint, and scale from surfaces, preparing them for subsequent processes like painting, welding, or coating.For automotive enthusiasts and mechanics, the Wire Brush Grinding Wheel is a game-changer. From removing stubborn surface contaminants to restoring old parts, this tool ensures a smooth and clean surface ready for paint or further refurbishment.Furthermore, contractors involved in construction projects can rely on the Wire Brush Grinding Wheel for efficient surface preparation of metal structures, ensuring optimal adherence for protective coatings.Conclusion:[Company Name] continues to establish itself as an industry leader by introducing groundbreaking products to enhance metalworking processes. The Wire Brush Grinding Wheel is a testament to the company's commitment to providing professionals with innovative and reliable tools that deliver outstanding results.Featuring an exceptional combination of wire bristles and cutting-edge grinding wheel technology, this new product offers unmatched performance, durability, and efficiency. [Company Name] has once again raised the bar in metal surface preparation, catering to a wide range of industries such as manufacturing, construction, automotive, and metal fabrication.Professionals can now embrace the Wire Brush Grinding Wheel as their go-to tool for achieving flawless metal surfaces, ensuring a seamless transition to subsequent processes such as welding, painting, and coating. With this latest innovation, [Company Name] reaffirms its status as a pioneer in the metalworking industry, consistently delivering premium solutions that meet the evolving needs of professionals worldwide.

Ceramic Abrasive Tools: Unveiling the Cutting-Edge Solution for Precision Grinding

Title: Ceramic Abrasive Tools: Revolutionizing the Cutting and Grinding Industry Introduction: With fast-paced technological advancements, the cutting and grinding industry has witnessed a significant transformation in recent years. Amongst the innovative solutions, Ceramic Abrasive Tools have emerged as a game-changer, offering increased efficiency, durability, and precision in various applications. This article explores the benefits and potential applications of ceramic abrasive tools, highlighting their impact on the industrial landscape. Paragraph 1:Ceramic Abrasive Tools, developed by industry-leading experts, have gained significant recognition owing to their incomparable performance and exceptional properties. These tools are manufactured using a proprietary ceramic grain technology, which enhances their cutting and grinding capabilities. With crystal structure vitrified bonds, the tools offer superior hardness and excellent self-sharpening qualities, making them ideal for industries ranging from automotive to aerospace.Paragraph 2:One of the key features that sets Ceramic Abrasive Tools apart is their impressive durability. The enhanced ceramic grain technology ensures that the tools have a longer lifespan and exhibit minimum wear, thereby reducing downtime and maintenance costs for industrial users. By incorporating advanced thermal stability attributes, these tools can operate at higher temperatures without any compromise in performance or accuracy.Paragraph 3:The versatility of Ceramic Abrasive Tools also allows them to be used across various applications, including precision grinding, profiling, edge sharpening, and stock removal. They are particularly well-suited for grinding hardened steels, cast iron, and high-temperature alloys, providing exceptional material removal rates while maintaining workpiece integrity. Additionally, the tools exhibit low levels of vibration, leading to a smoother grinding experience and improved surface finish quality.Paragraph 4:Safety is a paramount concern in any industrial setting, and Ceramic Abrasive Tools address this concern effectively. With the decreased risk of tool breakage and reduced spark generation, these tools ensure a safer operational environment. Additionally, their low levels of generated heat contribute to minimizing the chances of burns and injuries during extended use. The implementation of such safety features improves workplace conditions and elevates overall productivity.Paragraph 5:The application of Ceramic Abrasive Tools is not restricted to a specific sector but encompasses a wide range of industries. From automotive manufacturers requiring precision cutting and grinding to aerospace companies seeking the utmost reliability, these tools have found applicability in varied industrial domains. Furthermore, their compatibility with both handheld and automated machinery makes them an accessible choice for operations of all sizes.Paragraph 6:In light of the rapid growth of the cutting and grinding industry, manufacturers are continually striving to innovate and improve. Ceramic Abrasive Tools have emerged as an answer to the demands of modern industrial applications by offering increased efficiency, prolonged lifespan, and unrivaled precision. Their continued research and development ensure that the tools will keep evolving and meeting the ever-changing needs of the industrial sector.Conclusion:Ceramic Abrasive Tools have revolutionized the cutting and grinding industry by providing superior performance, enhanced durability, and increased safety. With their remarkable properties, these tools have proven to be a valuable asset in various industrial applications. As industries continue to evolve and demand higher standards of productivity and efficiency, ceramic abrasive tools are set to play a crucial role and redefine the boundaries of cutting and grinding operations.