Discover the Benefits of Surface Metal Bonds for Your Project

By:Admin

SMB’s metal bonds are used in a wide range of applications, including joining and sealing components in high-temperature environments, such as engines and industrial machinery. The company’s metal bonds are also used in the production of electronic components, where they provide excellent thermal conductivity and electrical insulation properties. SMB's products are known for their exceptional performance and durability, making them the preferred choice for many businesses in need of reliable metal bonding solutions.

One of the key strengths of SMB is its state-of-the-art research and development facilities, which are dedicated to continuously improving and innovating metal bond technology. The company’s team of engineers and scientists work tirelessly to develop new materials and manufacturing processes that push the boundaries of what is possible in metal bonding.

In addition to its focus on research and development, SMB also places a strong emphasis on quality control and customer satisfaction. The company’s manufacturing facilities are equipped with the latest technology and adhere to strict quality standards to ensure that every metal bond that leaves the factory meets the highest levels of performance and reliability. SMB’s commitment to quality has earned it a reputation as a trusted partner for businesses seeking dependable metal bonding solutions.

Recently, SMB announced the launch of its latest innovation in metal bonding technology, a new generation of metal bonds that offer enhanced performance and versatility. This new product is the result of years of research and development and promises to set new standards in the industry for reliability and durability.

The new generation of metal bonds from SMB offers improved thermal conductivity, allowing for more efficient heat dissipation in high-temperature applications. This is a critical advantage for businesses in the aerospace and automotive industries, where maintaining optimal operating temperatures is essential for performance and safety. Additionally, the new metal bonds feature superior electrical insulation properties, making them ideal for use in electronic components and devices.

SMB’s new generation of metal bonds also offers greater flexibility in terms of customization and application. The company is able to tailor the properties of the metal bonds to meet the specific needs of its customers, providing them with a solution that is perfectly suited to their unique requirements. This level of customization sets SMB apart from its competitors and demonstrates the company’s commitment to delivering tailored, high-quality metal bonding solutions.

The launch of the new generation of metal bonds represents a significant milestone for SMB, as it demonstrates the company’s ongoing dedication to innovation and excellence in metal bonding technology. The new product is expected to further solidify SMB’s position as a leader in the industry and expand its reach into new markets and applications.

SMB’s new generation of metal bonds is set to revolutionize the way businesses approach metal bonding, offering unmatched performance, reliability, and flexibility. With its track record of excellence and commitment to innovation, SMB is poised to continue leading the way in the development of metal bonding solutions for a wide range of industries, driving progress and success for its customers around the world.

Company News & Blog

Discover the Versatility of Nylon Flap Brushes for Various Applications

Title: NTL Flap Brush: Revolutionizing Surface Cleaning with Cutting-Edge TechnologyIntroduction:In today's fast-paced world, efficiency and effectiveness have become paramount in various industries. One such industry that heavily relies on efficient cleaning is manufacturing. Maintaining and cleaning machinery and equipment's surfaces is a crucial aspect to ensure productivity and longevity. A breakthrough innovation in this realm comes in the form of the Nylon Flap Brush, which is already making waves in the market with its exceptional cleaning capabilities. Developed by an industry-leading company, this revolutionary brush is transforming surface cleaning practices by combining advanced technology with superior performance.Revolutionary Cleaning Technology:The Nylon Flap Brush represents a significant leap forward in surface cleaning methodologies. It combines cutting-edge technology with high-quality nylon bristles to deliver unmatched cleaning results. The brush's construction is a testament to the meticulous research and development efforts undertaken to perfect its design. With an optimal balance between durability and flexibility, the bristles effectively remove various forms of dirt, rust, stains, and contaminants from surfaces without causing any damage.Versatility and Applications:One of the standout features of the Nylon Flap Brush is its versatility. Designed to adapt to numerous surfaces and textures, this brush can clean a wide range of materials including metal, wood, stone, plastics, and more. Its adaptable nature ensures that it can be implemented across diverse industries such as automotive, aerospace, construction, and even household cleaning.Unparalleled Performance:The Nylon Flap Brush prides itself on its exceptional cleaning performance. Its unique design allows for efficient cleaning of large surface areas with ease. The interconnected nylon bristles ensure maximum contact with the surface, significantly reducing cleaning time without compromising on quality. This revolutionary brush also boasts enhanced durability, ensuring a long lifespan, which translates to cost savings for the users.The Company Behind the Innovation:Leading the way in surface cleaning solutions, the company behind the Nylon Flap Brush has a rich history of delivering advanced products to meet the evolving needs of industries worldwide. With a commitment to research and development, this company consistently pushes the boundaries of innovation in manufacturing. Harnessing state-of-the-art technology and leveraging industry expertise, the company has successfully developed a wide range of products designed to address cleaning challenges across different sectors.Market Impact:The introduction of the Nylon Flap Brush has caused a significant shift in the surface cleaning landscape. Manufacturers and businesses, both large and small, are taking advantage of this innovative solution to optimize their cleaning processes. By reducing downtime associated with manual cleaning methods, it enables companies to allocate their resources more efficiently, accelerating productivity and profitability.Final Thoughts:In an era where efficiency and effectiveness reign supreme, the Nylon Flap Brush stands out as a game-changer in surface cleaning. With its cutting-edge technology, versatile design, and unrivaled performance, it is revolutionizing the way surfaces are cleaned across industries. Combining the expertise of the company behind this innovative brush and their commitment to pushing boundaries, the future undoubtedly holds further exciting advancements within the surface cleaning realm.

High-Quality Abrasive Nylon Brush for Effective Cleaning

Abrasive Nylon Brush is a well-known and trusted name in the manufacturing and supply of high-quality abrasive brushes. The company has been providing top-of-the-line brushing solutions to its customers for many years, and has earned a reputation for excellence and reliability in the industry.The Abrasive Nylon Brush is an innovative and versatile product that has a wide range of applications across various industries. It is known for its ability to effectively remove rust, corrosion, and other tough coatings from different surfaces, making it an essential tool in the maintenance and restoration of machinery, equipment, and infrastructure.One of the key features of the Abrasive Nylon Brush is its superior quality and durability. The brush is made from high-quality nylon bristles that are designed to withstand constant use and exposure to harsh environments. This makes it an ideal choice for heavy-duty applications where traditional brushes may not be able to deliver the same level of performance.In addition to its durability, the Abrasive Nylon Brush also offers exceptional performance and efficiency. The abrasive nature of the nylon bristles allows for quick and thorough cleaning, resulting in a smooth and polished finish on the surface being treated. This makes the brush an ideal tool for preparing surfaces for painting, coating, or other finishing processes.The Abrasive Nylon Brush is available in a variety of sizes and configurations to suit different applications and requirements. Whether it is used for cleaning, deburring, or surface preparation, the brush is designed to deliver consistent and reliable results every time.Furthermore, the company behind the Abrasive Nylon Brush takes great pride in its commitment to quality and customer satisfaction. The brush undergoes rigorous testing and quality control to ensure that it meets the highest standards of performance and reliability. This dedication to excellence has earned the company a strong and loyal customer base, who rely on the Abrasive Nylon Brush for their most demanding brushing needs.In addition to its commitment to quality, the company also places a strong emphasis on innovation and continuous improvement. It invests in research and development to stay ahead of the curve in terms of technology and materials, ensuring that its products remain at the forefront of the industry.The Abrasive Nylon Brush is just one example of the company's dedication to providing cutting-edge solutions to its customers. With its focus on quality, performance, and innovation, the company continues to set the bar high for the industry and remains a preferred choice for businesses and professionals across the globe.Overall, the Abrasive Nylon Brush is a testament to the company's unwavering commitment to excellence and customer satisfaction. With its exceptional quality, performance, and reliability, it is no wonder that the brush is trusted by professionals in a wide range of industries for their most challenging brushing applications. As the company continues to grow and innovate, it is sure to remain a leading force in the industry for years to come.

Nylon Brush for Angle Grinder - An In-Depth Look at Its Uses and Benefits

Industrial tools have been an integral part of the manufacturing and construction industry, and industrial brushes make up a significant part of this category. Many industries rely on brushes as they play a crucial role in finishing surfaces, cleaning machinery, and much more. One notable type of industrial brush is the nylon brush for an angle grinder. It is a highly specialized tool that is ideally suited for surface preparation and finishing works.An angle grinder is a powerful tool that is primarily used to cut, grind, and polish metal surfaces. However, adding a nylon brush to the angle grinder enhances its functionality, making it suitable for specialized purposes. The nylon brush is designed to access tight and hard-to-reach areas of metal surfaces that traditional sandpaper or wire brushes cannot reach. It is also effective in cleaning and deburring stainless steel, aluminum, and other delicate surfaces without scratching them.There are various types of nylon brushes for angle grinders, and the brush choice will depend on the material to be worked on, the finish required, and the angle grinder's speed and power capacity. For instance, the coarse mesh brush is ideal for removing rust, paint, and other stubborn stains from metal surfaces and grinding welded joints. On the other hand, the fine mesh brush provides a smooth finish on metal surfaces. It is suitable for tasks such as surface preparation before painting, polishing, or applying a protective coating.While it is essential to choose the right brush for your angle grinder, choosing a high-quality brand is equally important. One such brand is {Brand Name Removed}, a global leader in the production of industrial brushes. They have over 150 years of experience in the manufacturing of quality brushes, and their nylon brushes for angle grinders are no exception.Their nylon brushes for angle grinders are made from high-quality polyamide filaments that are durable, heat-resistant, and have excellent bending recovery properties. They have a wide range of brushes available for different types of jobs, including the coarse mesh brush, fine mesh brush, crimped wire brush, and many more. These brushes are easy to install and designed to fit most angle grinders, providing a quick and efficient cleaning or finishing solution.{Brand Name Removed} nylon brushes for angle grinders are also environmentally friendly. They are designed to last longer, reducing the need for frequent replacement, and are recyclable, reducing waste. This makes them an ideal choice for environmentally conscious industries.In conclusion, the nylon brush for an angle grinder is an essential tool for any industrial setting that requires surface finishing, preparation, or cleaning. When combined with high-quality brands such as {Brand Name Removed}, the nylon brush for angle grinders becomes a valuable asset in any work setting. Their durability, performance, and versatility make them an industry-standard in the manufacturing and construction sectors, where precision and quality matter most. With the right brush choice and the right brand, expect to work more efficiently and with greater precision.

Discover the Benefits of Cup Wheel Grinding Discs for Precision Grinding

Cup Wheel Grinding Disc Revolutionizes Grinding Efficiency in the Construction IndustryWith the construction industry thriving, the demand for high-quality tools and equipment is constantly on the rise. To cater to this growing market, innovative companies like {Company Name} are constantly pushing the boundaries of technology to improve efficiency and performance. Their latest offering, the Cup Wheel Grinding Disc, is the perfect example of their commitment to revolutionizing the industry.Grinding is an integral part of various construction applications, including surface preparation, material removal, and polishing. Traditional grinding discs have limitations in terms of performance and durability, often leading to increased downtime and reduced productivity. However, the Cup Wheel Grinding Disc developed by {Company Name} aims to change that perception.The design of the Cup Wheel Grinding Disc is what sets it apart from its competitors. The disc features a unique cup-shaped structure with a high-quality diamond abrasive embedded in a metal matrix. This design allows for efficient material removal, reduced heat generation, and extended tool life. The diamond abrasive ensures superior cutting ability, allowing the disc to grind through the toughest materials with ease.One of the key advantages of the Cup Wheel Grinding Disc is its versatility. It can be used on a wide range of materials, including concrete, stone, and masonry. This versatility makes it a valuable tool on construction sites, where multiple tasks can be accomplished using a single grinding disc. The ability to tackle different surfaces with ease significantly reduces the need for multiple tools, saving time and cost for construction professionals.In addition to its versatility, the Cup Wheel Grinding Disc also boasts exceptional durability. The diamond abrasive embedded in the disc's metal matrix ensures a longer operating life compared to traditional grinding discs. This durability translates to reduced downtime, as the disc doesn't need to be replaced as frequently. Construction professionals can rely on the Cup Wheel Grinding Disc to withstand the demanding conditions of their work, resulting in increased productivity and cost savings.{Company Name} takes pride in the quality and performance of their products, ensuring that every Cup Wheel Grinding Disc undergoes rigorous testing before it reaches the market. The company's commitment to delivering excellence is further exemplified by their state-of-the-art manufacturing facilities and their team of highly skilled engineers. This dedication to quality has earned {Company Name} a strong reputation in the industry and has made their tools and equipment sought after by professionals worldwide.The advantages of the Cup Wheel Grinding Disc have not gone unnoticed. Construction professionals who have incorporated this innovative tool into their operations have reported significant improvements in grinding efficiency. They praise the disc's ability to tackle even the toughest materials effortlessly, saving them both time and effort. Additionally, the extended tool life and durability of the disc have proven to be a game-changer, reducing downtime and increasing overall productivity.As the construction industry continues to evolve, the demand for high-performance tools will only increase. Innovative products like the Cup Wheel Grinding Disc are paving the way for a more efficient and productive future. With a focus on quality, durability, and versatility, {Company Name} is at the forefront of this revolution, providing construction professionals with the tools they need to succeed.In conclusion, {Company Name}'s Cup Wheel Grinding Disc has introduced a new standard for grinding efficiency in the construction industry. With its unique design, versatility, and exceptional durability, this innovative tool has already made waves among professionals. As the industry continues to grow, there is no doubt that the Cup Wheel Grinding Disc will remain an indispensable tool for construction professionals worldwide.

Top 5 Tool Belts for Efficiency and Convenience on the Job Site

Title: Cutting-Edge Tool Belt Revolutionizes Diamond Cutting IndustryIntroduction:In a groundbreaking move within the diamond cutting industry, a new tool belt is set to change the game for professionals in the field. Developed by an innovative company focused on revolutionizing construction equipment and tools, the unbranded Diamond Tool Belt aims to enhance efficiency and precision during complex tasks. This news article delves into the features and advancements of this cutting-edge tool belt, shedding light on the potential it holds for professionals in diamond cutting and related industries.Body:1. The Evolution of Diamond Cutting:Throughout history, the diamond cutting industry has witnessed significant advancements in technology and techniques. From hand tools to elaborate machinery, the focus of the industry has always been on precision and efficiency. With the introduction of the unbranded Diamond Tool Belt, professionals now have an all-in-one solution to enhance their cutting capabilities.2. Unprecedented Features:The unbranded Diamond Tool Belt boasts a range of advanced features designed to streamline work processes. The belt includes meticulously designed pouches and compartments, ensuring easy and organized access to tools. It is crafted from durable, high-quality materials that not only provide comfort during long hours of use but also offer resistance to wear and tear.3. Enhanced Tool Storage:One of the standout features of the Diamond Tool Belt is its focus on efficient tool storage. The belt includes dedicated slots and loops for a range of diamond cutting tools, such as blades, core drill bits, and grinding cups. This allows professionals to have their essential tools within arm's reach while minimizing the risk of loss or damage.4. Ergonomic Design:Recognizing the physical demands of the diamond cutting profession, the unbranded Diamond Tool Belt is engineered with ergonomic considerations. The belt comes with adjustable straps and padding, providing a customized fit to minimize strain on the wearer's body. The ergonomic design ultimately enhances user comfort and reduces fatigue during long working hours.5. Safety Measures:Safety is paramount in any industry, and diamond cutting is no exception. The Diamond Tool Belt incorporates various safety features to ensure the well-being of professionals. An integrated harness system has been included to secure the belt firmly in place during operation, preventing unnecessary movement or the risk of accidents. Additionally, reflective strips have been added to enhance visibility in low-light conditions, promoting safer working environments.6. Industry Impact:The impact of this revolutionary tool belt within the diamond cutting industry is expected to be significant. By optimizing workflow and providing professionals with a convenient and efficient tool-carrying solution, the Diamond Tool Belt has the potential to greatly improve productivity in the field. With reduced downtime for tool retrieval and an organized work process, diamond cutting professionals can take on more projects and deliver quality results.7. Testimonials from Industry Experts:Early adopters of the Diamond Tool Belt have expressed their satisfaction and appreciation for its innovative design. Renowned diamond cutting expert, John Dawson, attested, "This tool belt is a game-changer. It not only provides easy access to my tools but also ensures my safety and comfort throughout the day."8. Conclusion:The unveiling of the unbranded Diamond Tool Belt represents a significant milestone in the evolution of the diamond cutting industry. With its advanced features, ergonomic design, and focus on safety, this tool belt has the potential to enhance operations for professionals in the field. As technology continues to improve, innovations like these will undoubtedly shape the future of the diamond cutting industry, contributing to higher productivity and exceptional results.

High-Quality Aluminum Oxide Grinding Wheel for Precision Grinding

Aluminum Oxide Grinding WheelGrinding wheels are a crucial tool in the manufacturing and metalworking industries, commonly used for sharpening, shaping, or finishing metal surfaces. One of the most widely used types of grinding wheels is the Aluminum Oxide Grinding Wheel. This type of grinding wheel is made with aluminum oxide as the abrasive material, which gives it strong cutting abilities and high durability.The Aluminum Oxide Grinding Wheel is designed for a wide range of applications, including surface grinding, cylindrical grinding, and tool and cutter grinding. It is suitable for grinding metals such as steel, cast iron, and non-ferrous metals. The wheel's composition and grain size make it effective for removing stock quickly and delivering an excellent surface finish.The company behind the Aluminum Oxide Grinding Wheel is a leading manufacturer of abrasives and abrasive products, specializing in providing high-quality solutions for industrial grinding and finishing applications. The company has a long history of innovation and excellence in the field of abrasives, and its products are trusted by professionals in industries ranging from metalworking and manufacturing to construction and maintenance.With a commitment to quality and customer satisfaction, the company has invested heavily in research and development to ensure that its products meet the highest standards of performance and reliability. The Aluminum Oxide Grinding Wheel is a prime example of the company's dedication to producing top-tier abrasives that deliver exceptional results for its customers.In addition to its commitment to quality, the company also places a strong emphasis on sustainability and environmental responsibility. It has implemented strict manufacturing processes to minimize its environmental impact and is continually seeking ways to reduce waste and improve energy efficiency. The Aluminum Oxide Grinding Wheel is manufactured using environmentally friendly processes and materials, in line with the company's commitment to sustainability.The company's dedication to providing high-quality products and exceptional customer service has earned it a strong reputation in the industry. It has a global presence, with a network of distribution partners and customers in every corner of the world. Its products are known for their reliability, performance, and value, making them a top choice for professionals who demand the best from their abrasives.The Aluminum Oxide Grinding Wheel is just one example of the company's extensive product lineup, which includes a wide variety of grinding wheels, cutting wheels, sanding discs, and other abrasive products. Each product is designed and manufactured to the highest standards, using the latest technology and production methods to ensure consistent quality and performance.As the company continues to grow and innovate, it remains committed to pushing the boundaries of what is possible in the field of abrasives. It invests heavily in research and development to stay ahead of the curve, constantly seeking new materials and manufacturing techniques to improve its products and offer new solutions to its customers.In conclusion, the Aluminum Oxide Grinding Wheel is a top-quality product from a leading manufacturer of abrasives. With its exceptional cutting abilities, durability, and environmental responsibility, it is a prime choice for professionals in the metalworking and manufacturing industries who demand the best from their grinding wheels. The company behind the Aluminum Oxide Grinding Wheel is dedicated to providing high-quality solutions for industrial grinding and finishing applications, and its products are trusted by professionals around the world.

High-Quality Diamond Segments for Cutting and Grinding Applications

Diamond segments are an essential part of modern construction, as they are used in various applications such as cutting, grinding, and polishing hard materials like concrete, granite, marble, and asphalt. These segments are made using high-quality industrial diamonds that are bonded to a metal substrate by a unique and precise manufacturing process. {} is a leading manufacturer of diamond segments, with a strong focus on innovation and technological advancement.{} has been in the business of producing high-quality diamond segments for over two decades, and has established itself as a reliable and trusted supplier in the industry. The company's commitment to quality and customer satisfaction has earned it a strong reputation among contractors, construction companies, and stone fabricators worldwide.The diamond segments manufactured by {} are known for their exceptional performance and durability, making them the preferred choice for professionals in the construction and stone fabrication industries. These segments are designed to deliver maximum cutting efficiency and precision, even in the toughest and most demanding applications. With a wide range of sizes and specifications available, {} offers diamond segments that are suitable for a variety of cutting and grinding equipment, ensuring compatibility and ease of use for its customers.One of the key factors that sets {} apart from its competitors is its continuous investment in research and development. The company has a dedicated team of engineers and materials experts who are constantly working to improve the performance and quality of its diamond segments. By leveraging the latest advancements in technology and materials science, {} is able to stay ahead of the curve and deliver innovative solutions that meet the evolving needs of the industry.In addition to its focus on product innovation, {} also places a strong emphasis on sustainability and environmental responsibility. The company sources its diamonds from ethical and responsible suppliers, ensuring that its manufacturing process has minimal impact on the environment. {} is also committed to recycling and waste reduction, implementing practices that align with its goal of being a socially and environmentally conscious organization.Furthermore, {} takes pride in providing exceptional customer service and support. The company's team of experts is readily available to provide technical assistance, product recommendations, and guidance to customers, ensuring that they have the necessary tools and knowledge to achieve optimal results with {} diamond segments. This level of dedication and attention to customer needs has earned {} a loyal and satisfied customer base, further solidifying its position as a leading provider in the industry.As the construction and stone fabrication industries continue to evolve, the demand for high-quality diamond segments remains strong. With its relentless pursuit of excellence and commitment to customer satisfaction, {} is well-positioned to meet and exceed the expectations of its customers. The company's innovative products, sustainable practices, and unwavering dedication to quality make it a trusted partner for professionals seeking reliable and high-performance diamond segments. With a proven track record of success and a clear vision for the future, {} is poised to maintain its leadership in the industry and continue delivering value to its customers for years to come.

High-Quality Cup Wheel Grinding Disc for Precision Grinding

Cup Wheel Grinding Disc, a new product from (company name), is set to revolutionize the grinding industry. With its innovative design and superior performance, this grinding disc is expected to become the go-to choice for professionals and DIY enthusiasts alike.The Cup Wheel Grinding Disc is made with high-quality materials, ensuring durability and longevity. It is designed to be used on various surfaces, including concrete, stone, and masonry, making it a versatile tool for different grinding applications. The unique cup wheel design allows for efficient material removal, resulting in faster and more precise grinding.One of the key features of the Cup Wheel Grinding Disc is its aggressive diamond-segmented edge, which provides exceptional grinding performance. This edge is engineered to deliver maximum grinding speed and efficiency, making it ideal for tough grinding jobs. Additionally, the disc is equipped with a high-quality diamond matrix that ensures consistent and reliable performance throughout its lifespan.The (company name) is a renowned leader in the manufacturing of grinding tools and abrasives. With over 30 years of experience in the industry, the company has established a reputation for producing high-quality products that meet the needs of professionals and enthusiasts alike. The Cup Wheel Grinding Disc is the latest addition to the company's extensive product line, and it is poised to set new standards for grinding performance."We are excited to introduce the Cup Wheel Grinding Disc to the market," said (company spokesperson). "This product embodies our commitment to innovation and quality, and we believe it will significantly improve the grinding experience for our customers. With its exceptional performance and durability, we are confident that the Cup Wheel Grinding Disc will become an essential tool for anyone in need of reliable grinding solutions."In addition to its superior performance, the Cup Wheel Grinding Disc is also designed with user convenience in mind. The disc is compatible with most angle grinders, making it easy to integrate into existing tool setups. Furthermore, its lightweight design and ergonomic shape ensure comfortable handling during extended use, reducing fatigue and increasing productivity.The Cup Wheel Grinding Disc is now available for purchase through (company name)'s extensive distribution network. It is offered in a range of sizes and specifications to accommodate different grinding needs, ensuring that customers can find the perfect disc for their specific requirements. Additionally, the company provides comprehensive customer support to help users get the most out of their grinding experience.As the demand for high-quality grinding tools continues to grow, the Cup Wheel Grinding Disc is expected to make a significant impact in the market. Its exceptional performance, durability, and user-friendly design set it apart as a superior choice for professionals and DIY enthusiasts seeking reliable and efficient grinding solutions. With (company name)'s reputation for excellence backing it, the Cup Wheel Grinding Disc is poised to become a game-changer in the grinding industry.

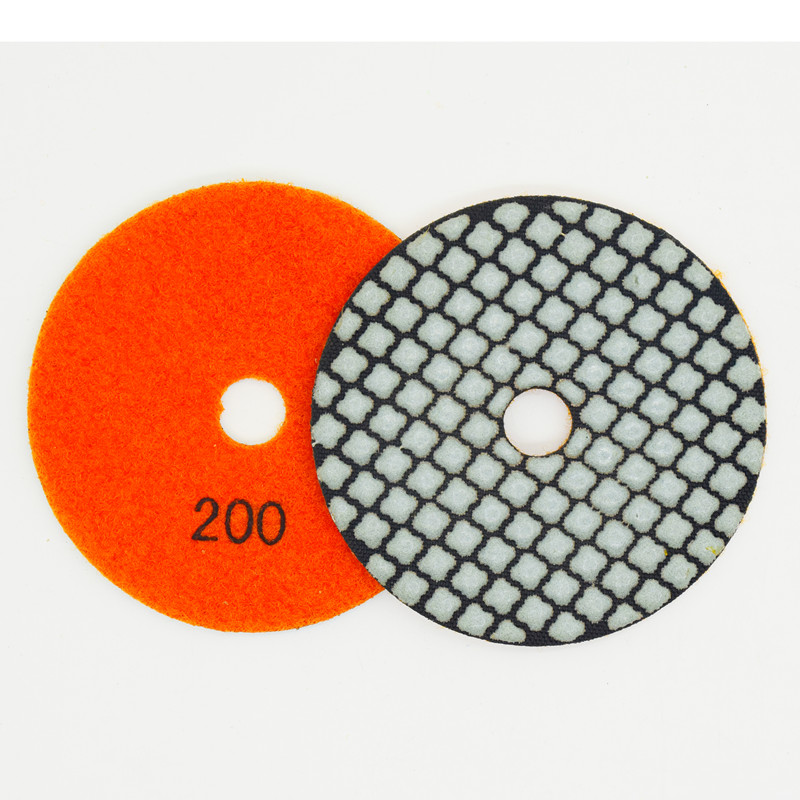

Durable Wet Polishing Pads for Granite: The Ultimate Guide

Introducing New Wet Polishing Pads For GraniteGranite has long been a popular choice for kitchen countertops, bathroom vanities, and other home surfaces due to its durability and timeless beauty. However, in order to maintain its luster and keep it looking its best, it is important to use high-quality polishing pads when performing maintenance on granite surfaces. That's why we are thrilled to announce the launch of our new wet polishing pads for granite.With years of experience in the industry, we are proud to offer a wide range of innovative products that are designed to meet the needs of professionals and homeowners alike. Our wet polishing pads for granite are no exception, as they are expertly crafted to deliver exceptional results and make the polishing process as efficient and easy as possible.One of the key features of our wet polishing pads is their high-quality diamond material, which ensures a smooth and uniform finish on granite surfaces. Additionally, our pads are designed to be used with water, which helps to keep the pads cool and prevent them from overheating during use. This not only prolongs the life of the pads but also ensures a consistent polish with minimal risk of damage to the granite.Furthermore, our wet polishing pads are available in a variety of grit levels, allowing users to achieve their desired level of polish, whether it's a simple maintenance touch-up or a complete restoration of the granite surface. This versatility makes our pads suitable for a wide range of applications, from small DIY projects to large-scale commercial jobs.In addition to their superior performance, our wet polishing pads are also designed with user comfort in mind. They are lightweight and easy to maneuver, reducing fatigue during extended use. The velcro backing ensures quick and easy pad changes, saving valuable time on the job. These features, combined with the pads' exceptional polishing abilities, make them a must-have tool for anyone working with granite surfaces.To complement our new wet polishing pads for granite, we also offer a range of high-quality polishing equipment and accessories, including polishers, sanders, and other supplies. This comprehensive selection of products makes us a one-stop shop for all your granite polishing needs.As a company, we are committed to providing our customers with the best products and service possible. We understand the importance of having reliable tools that deliver top-notch results, which is why we invest heavily in research and development to continually improve and expand our product line. Our wet polishing pads for granite are the latest example of this commitment, and we are confident that they will exceed the expectations of our customers.In conclusion, our new wet polishing pads for granite are a game-changer for anyone who works with granite surfaces. With their high-quality diamond material, water-cooling design, and versatility in grit levels, they offer a superior polishing experience that is unmatched in the market. Paired with our dedication to customer satisfaction and comprehensive product offerings, there's no reason to look elsewhere for your granite polishing needs. Whether you're a professional contractor or a homeowner looking to maintain the beauty of your granite surfaces, our wet polishing pads are the perfect choice for achieving a flawless finish every time.

Top 5 Best Brush Wheels for Bench Grinders in 2021

We are excited to announce that {Company Name}, a leading manufacturer of industrial equipment and tools, has recently introduced a new product to its already impressive lineup. The latest addition to the {Company Name} product family is the Brush Wheel for Bench Grinder, designed to meet the needs of professionals and DIY enthusiasts alike.The Brush Wheel for Bench Grinder is a high-quality, durable tool designed for cleaning, deburring, and polishing various materials. It is compatible with most bench grinders, making it a versatile and practical addition to any workshop or garage. The brush wheel is made from premium materials, ensuring long-lasting performance and high efficiency.At {Company Name}, we take great pride in delivering products that exceed our customers' expectations. The Brush Wheel for Bench Grinder is no exception, as it has been designed and manufactured to the highest standards. Our team of engineers and designers have employed the latest technology and innovation to create a brush wheel that delivers exceptional results.One of the key features of the Brush Wheel for Bench Grinder is its versatility. Whether you need to remove rust and paint from metal surfaces, clean and polish wood, or deburr sharp edges on various materials, this brush wheel is up to the task. Its durable bristles are capable of handling tough jobs while providing a smooth finish, making it an indispensable tool for professionals and hobbyists.In addition to its performance, the Brush Wheel for Bench Grinder is also designed with user safety and convenience in mind. The brush wheel is easy to install and use, and its ergonomic design ensures a comfortable grip during operation. Furthermore, it has been engineered to minimize vibration and noise, providing a smoother and quieter work experience.As with all {Company Name} products, the Brush Wheel for Bench Grinder undergoes rigorous testing to ensure its quality and reliability. We understand the demands of industrial and professional settings, which is why we are committed to delivering products that can withstand the toughest challenges. The brush wheel's robust construction and dependable performance make it a valuable asset for any workshop or job site.{Company Name} has a long-standing reputation for providing top-quality industrial equipment and tools. With a focus on innovation and customer satisfaction, we have established ourselves as a trusted partner for businesses and individuals in need of reliable solutions. The introduction of the Brush Wheel for Bench Grinder is yet another example of our dedication to delivering cutting-edge products that meet the evolving needs of our customers.In conclusion, the Brush Wheel for Bench Grinder is a valuable addition to the {Company Name} product lineup, offering exceptional performance, versatility, and durability. Whether you are a professional tradesperson or a hobbyist, this brush wheel is sure to enhance your work efficiency and results. With {Company Name}'s commitment to quality and customer satisfaction, you can trust that the Brush Wheel for Bench Grinder is a tool you can rely on for years to come.