Boost Performance with Top-Quality Backer Pads for Orbital Sanders

By:Admin

Introduction:

In today's dynamic world, technology is constantly evolving to simplify tasks and enhance efficiency. In the woodworking industry, the introduction of the innovative Backer Pad for Orbital Sanders is set to revolutionize the sanding process, delivering superior results that meet the demands of professional woodworkers. This groundbreaking accessory is expected to redefine the standards of craftsmanship, offering an unparalleled experience for users across the globe.

The Evolution of Orbital Sanders:

Orbital sanders have long been a staple tool in woodworking, allowing craftsmen to achieve a smooth and flawless finish on various surfaces. However, despite their efficiency, many professionals have encountered limitations with traditional sanding pads that did not deliver optimal results. Recognizing this gap, {Company Name} has unveiled the cutting-edge Backer Pad for Orbital Sanders, aiming to overcome these challenges and revolutionize the sanding experience.

Introducing the Backer Pad for Orbital Sanders:

The Backer Pad is an ingeniously engineered accessory designed to optimize sanding efficiency, enabling woodworkers to achieve unrivaled precision, consistency, and quality. Crafted with the finest materials, this revolutionary product ensures a seamless sanding process, eliminating imperfections while preserving the integrity of the workpiece.

Unparalleled Versatility:

The Backer Pad for Orbital Sanders boasts unparalleled versatility, accommodating a wide range of sandpaper grits and sizes. Whether it's coarse sanding to smoothen rough surfaces or fine grits for a polished finish, this accessory provides woodworkers with the flexibility to tailor their results as per their specific requirements. This adaptability significantly reduces the need for multiple sanding devices, simplifying the workflow and saving valuable time.

Enhanced Durability and Productivity:

Durability is a prime concern for woodworking professionals, and the Backer Pad delivers impeccably in this aspect. Engineered with premium materials, this accessory is built to withstand rigorous usage, ensuring prolonged service life. Its exceptional stability and resistance to wear and tear contribute to a higher productivity level, empowering woodworkers to focus on their craft without any interruptions.

Advanced Dust Extraction System:

Dust accumulation is a common challenge in the sanding process, affecting both the performance and the health of woodworkers. Understanding this concern, {Company Name}'s Backer Pad incorporates a state-of-the-art dust extraction system. By efficiently capturing and controlling dust, this accessory maintains a clean work environment, optimizes visibility, and minimizes the risk of respiratory issues.

Ergonomic Design for Comfort and Control:

{Company Name}'s commitment to its users extends beyond functionality, incorporating ergonomic design features into the Backer Pad. The lightweight yet robust construction provides woodworkers with a comfortable grip, reducing fatigue during extended sanding sessions. Additionally, the design promotes optimal control over the sanding process, enhancing safety and accuracy even in intricate projects.

Industry Feedback and Recognition:

Since its introduction, the Backer Pad for Orbital Sanders has garnered rave reviews from industry professionals both locally and internationally. Recognizing its significant impact on the woodworking sector, it has gained accolades and endorsements, solidifying its position as a game-changing accessory.

Conclusion:

In the ever-growing woodworking industry, the Backer Pad for Orbital Sanders stands out as a game-changing innovation that enhances productivity, efficiency, and craftsmanship. With its impeccable performance, versatility, and ergonomic design, this revolutionary accessory is set to redefine the sanding experience for professionals worldwide. As the woodworking landscape continues to evolve, {Company Name}'s commitment to innovation reaffirms its position as a leader in providing cutting-edge solutions to woodworkers, empowering them to achieve unparalleled results.

Company News & Blog

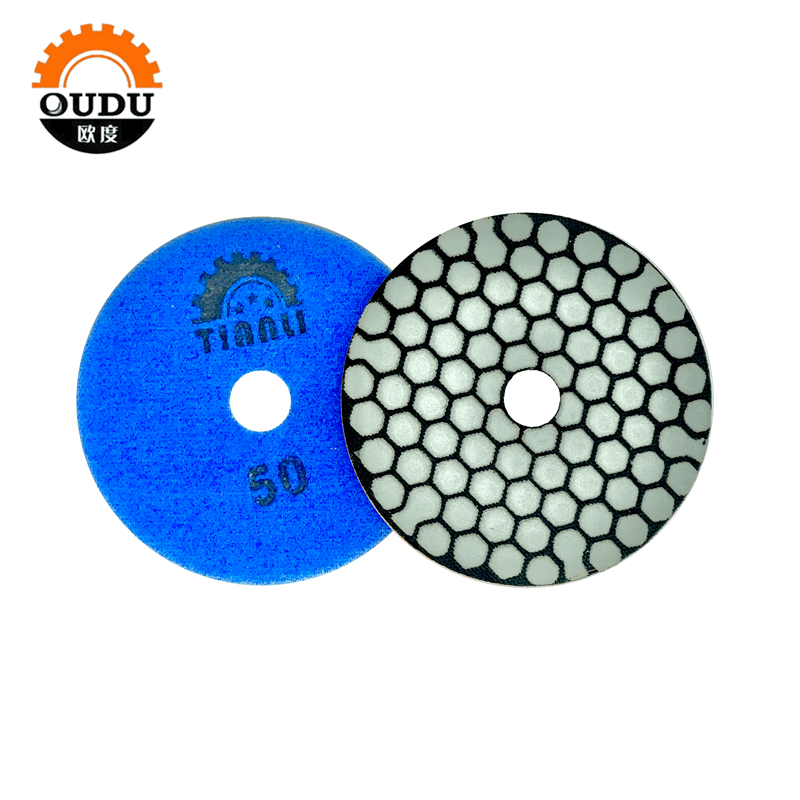

Floor Polishing Pad: Achieve Gleaming Floors with Professional Grade Tools

Floor Polishing Pad: A New Generation of High-Quality Polishing ToolsFloor polishing is an essential task in any commercial or residential building. However, it is often a tedious and time-consuming task that requires the use of specialized tools and high-quality equipment. This is where floor polishing pads come into the picture. The latest innovation in the field of floor polishing, floor polishing pads are designed to make the process faster, easier, and more efficient.Floor Polishing Pad is a leading company that specializes in the production of high-quality floor polishing pads. The company has been in the industry for more than a decade, and over the years, it has established itself as a trusted name in the market. Floor Polishing Pad offers a wide range of polishing pads that are designed to cater to the different needs of its customers.One of the most innovative products from the company is its Diamond Floor Polishing Pads. This product is designed to provide a long-lasting and superior quality finish on various types of floors, including marble, granite, concrete, terrazzo, and more. These pads are made from high-quality materials, and they are designed to deliver consistent performance over a long period.The Diamond Floor Polishing Pads are available in different sizes and grit levels, making them suitable for various polishing tasks. They are easy to use and can be attached to any standard floor buffer or polisher. The pads are also compatible with different polishing compounds, ensuring that customers can achieve the desired finish.Apart from the Diamond Floor Polishing Pads, the company also offers other innovative products. The Resin Floor Polishing Pads, for instance, are designed to provide a high-gloss finish on concrete floors. These pads are made from resin and are suitable for wet and dry polishing. The company also offers a range of Polishing Buffs that are designed to provide a high-quality finish on metal and glass surfaces.The success of Floor Polishing Pad can be attributed to its commitment to quality and customer satisfaction. The company has a team of experienced professionals who are dedicated to ensuring that its customers get the best value for their money. The company also invests heavily in research and development to ensure that its products remain innovative and relevant in the market.Floor Polishing Pad has a robust distribution network that allows it to reach customers in different parts of the world. The company has also established partnerships with other industry players, including equipment manufacturers, to ensure that its products are compatible with the latest polishing tools.In conclusion, Floor Polishing Pad is a leading company that specializes in the production of high-quality floor polishing pads. The company's innovative products, including its Diamond Floor Polishing Pads, Resin Floor Polishing Pads, and Polishing Buffs, have won the trust of its customers. With its commitment to quality and customer satisfaction, Floor Polishing Pad is poised to remain a dominant player in the market.

Top 7 Inch Grinding Wheel: Essential Tool for Precision and Efficiency

Title: High-Quality 7-Inch Grinding Wheel Now Available for Enhanced Precision and EfficiencyIntroduction:In a recent development, a renowned company, specializing in industrial tools and machinery, has released its latest offering - a top-notch 7-inch grinding wheel. Designed to deliver superior performance, this all-new grinding wheel promises enhanced precision and efficiency. The company, known for its commitment to quality and innovation, has once again raised the bar in the field of industrial abrasives.[Company Name - OPTIONAL]:With over [number of years] of experience, and a strong presence in the industrial sector, this company has become a trusted name for professionals and hobbyists alike. Established with the goal of providing cutting-edge tools and machinery, the company has consistently delivered products that exceed the expectations of its customers. Renowned for its commitment to quality, reliability, and customer satisfaction, the company continues to be a prominent player in the industry.The 7-Inch Grinding Wheel:The newly launched 7-inch grinding wheel is the result of extensive research and development efforts by the company's team of experts. Crafted with precision, the wheel offers exceptional durability and performance, making it an ideal choice for various grinding applications. Equipped with advanced features, this grinding wheel ensures an efficient workflow while adding a touch of convenience to the user's experience.The key features of the 7-inch grinding wheel include:1. High-Quality Materials: Crafted from premium-grade materials, this grinding wheel offers excellent durability and long-lasting performance, even under challenging working conditions. Its construction guarantees minimal wear and tear, ensuring a prolonged product lifespan.2. Precise Grinding: The 7-inch wheel has been engineered to deliver precise grinding and smoothing results. Its balanced design ensures smooth operation and reduced vibrations, allowing for consistent and accurate material removal. This feature enables users to achieve desired finishes promptly and efficiently.3. Versatility: The grinding wheel is compatible with various materials, including metal, stone, ceramics, and more. Its versatility enables users to tackle a wide range of applications, making it an indispensable tool in industries such as construction, automotive, and manufacturing.4. Easy Installation: Designed with user convenience in mind, this grinding wheel features a hassle-free installation process. Equipped with a universal spindle size, it can be quickly mounted on most grinders, reducing downtime and improving productivity.5. Enhanced Safety: Prioritizing user safety, the grinding wheel incorporates features such as reinforced construction and adequate heat dissipation. These safety measures minimize the risk of accidents, ensuring a secure working environment.6. Performance Efficiency: The 7-inch size of the wheel allows for greater surface coverage, resulting in improved efficiency and time-saving benefits. The wheel's optimal composition guarantees smooth and consistent grinding, reducing the need for frequent tool changes.Conclusion:The introduction of the high-quality 7-inch grinding wheel has made a significant impact on professionals and hobbyists in various industries. With its durable construction, precise grinding capabilities, and enhanced safety features, this tool is set to elevate the standards of grinding efficiency, while maintaining the company's reputation for producing reliable and innovative products.As the company continues to pave the way in the field of industrial tools and machinery, the 7-inch grinding wheel stands out as a testament to their commitment to delivering superior performance and meeting the evolving needs of their customers.

Newly Developed Woven Polishing Pads Offer Enhanced Performance and Durability

Nov-Woven Polishing Pad Sets New Industry Standard for Surface Finishing[City Name], [Date] - The surface finishing industry has just witnessed the release of a groundbreaking product, the Nov-Woven Polishing Pad. Manufactured by a leading company in the field, this pads introduction is set to revolutionize the way surfaces are polished, providing both professionals and consumers with unmatched efficiency and outstanding results.The Nov-Woven Polishing Pad, developed by an innovative and forward-thinking team of experts, is a culmination of years of research, development, and testing. This cutting-edge product aims to address the limitations experienced by traditional polishing pads, providing a solution that exceeds expectations and sets a new industry standard.One of the most remarkable features of the Nov-Woven Polishing Pad is its superior durability. Unlike other pads on the market, this pad has been designed to withstand the rigors of heavy-duty polishing tasks, ensuring a long lifespan and consistent performance. With its enhanced durability, users can expect to achieve impressive results even after extended use, saving both time and resources in the long run.The innovation behind the Nov-Woven Polishing Pad lies in its unique weave structure and advanced material composition. The pad's surface is meticulously engineered to deliver optimal contact with the material being polished, resulting in faster and more efficient performance. This innovative design boasts dual-action capabilities, allowing it to remove scratches and imperfections while simultaneously enhancing shine, all in one easy step.Additionally, the Nov-Woven Polishing Pad offers an exceptional level of versatility, making it suitable for a wide range of applications across various industries. Whether it's automotive, construction, or furniture, this polishing pad is guaranteed to provide outstanding results on any surface. Its adaptability to different materials, such as metal, wood, or plastic, further enhances its appeal to professionals and DIY enthusiasts alike.The company behind this groundbreaking product has a strong reputation for delivering high-quality surface finishing solutions. With a long-standing presence in the industry, they have consistently pushed the boundaries of innovation, introducing products that have revolutionized the way surfaces are treated. Their commitment to research and development has earned them the trust and loyalty of customers worldwide.Furthermore, sustainability is a core value of the company, and this philosophy is reflected in the production of the Nov-Woven Polishing Pad. Manufactured using eco-friendly materials and processes, this pad not only reduces environmental impact but also meets the growing demands for sustainable solutions in the industry. By choosing this product, customers can contribute to the preservation of our planet without compromising on quality.The Nov-Woven Polishing Pad has already made waves among industry professionals and early users. Feedback has been overwhelmingly positive, with many praising its effectiveness, durability, and ease of use. Experts anticipate that this product will quickly become a must-have in workshops, garages, and households worldwide.In conclusion, the Nov-Woven Polishing Pad sets a new industry standard for surface finishing. With its superior durability, innovative design, and remarkable versatility, this product provides a game-changing solution for all polishing needs. Backed by a reputable company known for their dedication to quality and sustainability, the Nov-Woven Polishing Pad is set to revolutionize the way surfaces are treated, offering professionals and consumers alike a superior polishing experience.

Understanding the Role of Covalent Bonds in Metal or Nonmetal Elements

Title: Understanding Covalent Bonds: Bridging Metals and NonmetalsIntroduction:In the realm of chemistry, the concept of covalent bonds plays a crucial role in explaining the behavior of elements and compounds. The formation of covalent bonds between metals and nonmetals is particularly intriguing, as it allows for the creation of unique materials with diverse properties. This article will delve into the world of covalent bonds, elucidating their significance and exploring their applications across various industries.Understanding Covalent Bonds:Covalent bonding occurs when two atoms share electrons to achieve a stable electron configuration. These bonds are prevalent between nonmetals, as they typically have higher electronegativity values, the tendency to attract electrons, compared to metals. The sharing of electrons allows both atoms to attain a complete outer electron shell, resulting in a stable molecule.Importance of Covalent Bonds:Covalent bonds between metals and nonmetals yield compounds known as metalloids or semiconductors. These materials possess properties that are intermediate between conductors (metals) and insulators (nonmetals), making them integral to various industries ranging from electronics to energy storage.Applications in Semiconductor Industry:Semiconductors are fundamental components in the electronics sector, driving technological advancements. Covalent bonding involving metals and nonmetals enables the creation of semiconducting materials such as silicon (Si) and germanium (Ge). These elements possess unique properties that allow them to be used in microchips, transistors, and solar panels.Silicon, a widely used semiconductor, demonstrates the remarkable potential of covalent bonds in enabling technological progress. Its ability to both conduct and insulate electricity makes it a primary material for integrated circuits. Moreover, the covalent bonding between silicon atoms facilitates the formation of a crystalline lattice, providing stability and efficient electron flow, thereby enhancing the performance of electronic devices.Covalent Bonding in Chemical Industry:The chemical industry extensively relies on covalent bonds to synthesize compounds with desirable properties. By combining metals and nonmetals, chemists can manipulate covalent bonds to modify the reactivity and stability of substances.Organometallic compounds, for instance, are widely used in catalysis. By incorporating metals into organic molecules via covalent bonding, catalysts with remarkable efficiency and selectivity can be developed. Such catalysts play a crucial role in the production of pharmaceuticals, plastics, and other chemical products, making them vital for sustainable industrial processes.Exploring Covalent Bonds in Materials Science:Materials science utilizes covalent bonds to engineer materials with superior strength, electrical conductivity, and thermal properties. Carbon, a nonmetal, forms covalent bonds with itself to create an extensive array of materials, including diamond, graphite, and carbon nanotubes.Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, epitomizes the extraordinary potential of covalent bonds in material design. Its unrivaled strength, elasticity, and electrical conductivity make it a promising candidate for advancements in electronics, energy storage, and even medicine.Advancements in Covalent Bond Research:Research surrounding covalent bonds is rapidly evolving, with scientists exploring new frontiers in materials science and catalysis. Understanding the intricacies of covalent bonding allows for the development of novel materials with enhanced properties and improved industrial processes.In conclusion, covalent bonds play a pivotal role in bridging metals and nonmetals, giving rise to diverse materials with unique properties. The applications of covalent bonding across various industries highlight its significance in shaping technological advancements and promoting sustainable practices. As research continues, we can expect exciting breakthroughs that further harness the potential of covalent bonds for the betterment of society.

New Study Shows Growing Demand for Metal Abrasives in Industrial Sector

Title: Metal Abrasives - Revolutionizing Manufacturing Through Cutting-Edge TechnologiesIntroduction: Metal Abrasives has emerged as a titan in the manufacturing industry, transforming the way professionals approach metalworking processes. With a commitment to innovation, quality, and sustainability, Metal Abrasives has earned its place as a global leader in metal abrasive solutions. Company Overview:Metal Abrasives, founded in 1990, is a privately-owned company headquartered in [Location]. With a dedicated team of experts, the company specializes in the production and distribution of a wide range of metal abrasives, catering to diverse industries such as automotive, aerospace, construction, and marine.The company's manufacturing facility is equipped with state-of-the-art technology, allowing Metal Abrasives to consistently deliver high-quality products that meet and exceed industry standards. Metal Abrasives takes pride in its commitment to sustainability, ensuring that its processes and products align with environmentally friendly practices.1. Pioneering Metal Abrasives:Metal Abrasives has continuously pushed the boundaries of metalworking technologies, offering cutting-edge solutions that enable professionals to achieve superior results. Through extensive research and development, the company has introduced several game-changing innovations to the market.a. SmartGrind: SmartGrind is Metal Abrasives' proprietary abrasive technology, utilizing advanced sensors and data analytics to optimize cutting and grinding processes. By monitoring parameters such as temperature, vibration, and pressure, SmartGrind ensures precision, efficiency, and enhanced control, reducing material waste and increasing productivity.b. NanoCoat:NanoCoat, a breakthrough surface treatment developed by Metal Abrasives, enhances the durability and performance of their metal abrasive products. This nanotechnology-based coating offers improved resistance to wear, reducing tool failure and extending overall product lifespan. NanoCoat also provides a smooth, consistent surface finish, facilitating better paint adhesion and coating uniformity.2. Commitment to Quality and Compliance:Metal Abrasives places utmost importance on maintaining the highest quality standards across all its products. The company adheres to international certifications and exceeds industry requirements, ensuring customer satisfaction and long-term reliability.a. ISO 9001:Metal Abrasives is proud to be ISO 9001 certified, signifying its commitment to quality management systems. This certification validates the company's dedication to meeting customer expectations through continual improvement and consistently delivering products that meet stringent quality benchmarks.b. Regulatory Compliance:Metal Abrasives strictly adheres to occupational health and safety regulations, minimizing operational risks and safeguarding the well-being of its workforce. Additionally, the company closely follows environmental standards, employing eco-friendly manufacturing processes and materials, thus reducing its carbon footprint and contributing to sustainability initiatives.3. Global Reach and Customer Support:With a vast network of distributors and partners worldwide, Metal Abrasives ensures its products reach customers across the globe. The company has established strong relationships with industry leaders, offering excellent customer support, technical assistance, and tailored solutions to meet specific requirements.Moreover, Metal Abrasives conducts regular training programs, workshops, and seminars for professionals, enabling them to optimize their metalworking processes, elevate their skills, and stay up-to-date with emerging trends in the industry.4. Future Expansion and Sustainability:Metal Abrasives remains committed to continuous growth and expansion. The company invests significantly in research and development to develop breakthrough technologies while keeping sustainability at the forefront of its operations.a. Recycling Initiatives:Metal Abrasives actively promotes recycling programs, encouraging the responsible disposal and utilization of used metal abrasives. By implementing a closed-loop system, the company reduces waste generation and raw material consumption, contributing to a greener future.b. Social Responsibility:Metal Abrasives believes in giving back to the community and actively supports philanthropic initiatives. Through partnerships with charitable organizations, the company contributes to education and healthcare programs, fostering positive social change.Conclusion:Metal Abrasives' relentless pursuit of innovation, commitment to quality, and dedication to sustainability have positioned the company as an industry forerunner. With groundbreaking technologies like SmartGrind and NanoCoat, Metal Abrasives enables professionals across sectors to elevate their metalworking processes, resulting in enhanced efficiency, reduced waste, and superior end products. As the company continues to expand its global reach, Metal Abrasives remains focused on shaping a sustainable future for the manufacturing industry.

Top Ceramic Sanding Belts for Superior Grinding Results

Ceramic Sanding Belts: The Future of Industrial AbrasivesSanding is a crucial process in any manufacturing industry that requires precision and perfection. Be it metal, wood, or any other material; the process of sanding helps to give the perfect finish to the desired product. The abrasive industry has come a long way with developments in technology and materials. One of the most significant innovations in the abrasive industry is the Ceramic Sanding Belts.Ceramic Sanding Belts are a relatively new type of abrasive that has been gaining popularity in industrial manufacturing. These belts are made from a tough and durable ceramic material that delivers excellent performance, much better than conventional abrasives. These ceramic belts are used for heavy stock removal, grinding, and deburring. They are designed to work on a wide variety of metals, such as stainless steel, titanium, and aluminum.Ceramic Sanding Belts have several benefits over traditional abrasives. The first and most important benefit is the durability of the ceramic material, which means that these belts can last up to five times longer than standard sanding belts. This increased lifespan reduces the replacement costs significantly, making them more cost-effective. Secondly, the ceramic material used in these belts is less likely to wear, tear, or become dull, even when subjected to high pressures and high temperatures. This means that they can withstand heavy-duty operations without breaking or wearing out.Another remarkable benefit of Ceramic Sanding Belts is their self-sharpening feature. When conventional sanding belts get dull, they need to be replaced or sharpened manually. In contrast, Ceramic Sanding Belts have a higher self-sharpening property, which means that they sharpen themselves while in use, without any intervention from the operator. This makes the process of sanding more efficient and less time-consuming, as there is no need to stop the machine to replace or sharpen the belt.Ceramic Sanding Belts are also well-known for their consistent performance. They deliver a uniform finish on every pass, which is critical for any manufacturing process that requires precision and accuracy. These belts ensure that the final product is of the desired quality, whether it is a shiny surface or a deburred edge.One company that has been leading the way in developing Ceramic Sanding Belt technology is {}. With over twenty years of experience in the abrasive industry, they have been at the forefront of innovation and technological advancement. The company has designed and manufactured a vast range of Ceramic Sanding Belts that have been used in various industries, including automotive, aviation, marine, and woodworking.Their Ceramic Sanding Belts are engineered to provide optimal results in different applications. They offer belts with varying grit levels, ranging from 36-grit for heavy stock removal to 120-grit for surface finishing. The company also provides belts with different backing materials to suit various types of machines and applications.In addition to Ceramic Sanding Belts, {} also produces other abrasive products to meet customer requirements and offer complete solutions to their customers. Their extensive product range includes flap discs, fibre discs, sanding sheets, and even abrasive rolls. The company also offers customized solutions to meet specific applications.{} is committed to providing quality products and excellent customer service. They understand the importance of providing high-quality abrasives and the role they play in the manufacturing process. The company has invested heavily in research and development to ensure that their products are at the forefront of innovation and meet the changing needs of their customers.In conclusion, Ceramic Sanding Belts are the future of the abrasive industry, and companies like {} are pushing the boundaries of technology to provide better solutions to their customers. By offering a range of Ceramic Sanding Belts with varying grit levels, backing materials, and customized options, {} is setting the standard for the industry. With their commitment to providing quality products, {} is sure to continue being at the forefront of innovation in the abrasive industry.

Top Trends in Cutting Tools for 2021

Cutting Tools: A Critical Component of Precision ManufacturingIn the world of precision manufacturing, nothing is more important than accuracy and consistency. Whether you are producing aerospace components, medical implants, or automotive parts, the ability to cut precisely and consistently is essential for producing high-quality finished products. That's where cutting tools come in - they are the critical component that enables precise and efficient machining.One leading manufacturer of cutting tools is a company that has been in business for over 50 years. Over this span of time they have developed a reputation for producing some of the best cutting tools in the industry, known for their precision, durability, and consistency. With a focus on research and development, this company has been committed to staying on the cutting edge - continually refining their product line and staying up-to-date with the latest manufacturing technologies.One of the unique strengths of this company is their ability to manufacture a wide range of cutting tools to meet virtually any machining need. From end mills and drills to taps and reamers, their product line includes hundreds of different types of cutting tools, each designed to cut specific materials in specific ways. They even offer custom cutting solutions for customers with unique machining needs.So what makes their cutting tools so special? One key factor is the materials they use. From high-speed steel to carbide and diamond, they use only the best raw materials to ensure durability and precision. They also use state-of-the-art manufacturing technologies, including CNC grinding machines and other automated equipment, to produce cutting tools with tolerances that are measured in microns.But it's not just about the quality of the materials - it's also about the design. Every cutting tool they produce is engineered to cut precisely and efficiently, with the smallest possible amount of waste and the longest possible tool life. They use advanced software to design their cutting tools and simulate their performance, ensuring that they will perform as expected in even the most demanding machining applications.This commitment to excellence has earned them a reputation as a top supplier of cutting tools to some of the world's leading manufacturers. Their products are used in a wide range of industries, from aerospace and defense to medical devices, automotive, and more. And with a global network of distributors and sales representatives, they are able to support customers around the world with fast delivery and technical support.So what does the future hold for cutting tools? With the ongoing evolution of manufacturing technologies, the demand for ever-more-precise and efficient cutting tools will only continue to grow. Companies like this one are well-positioned to stay ahead of the curve, investing in R&D to develop the next generation of cutting tools that will enable even greater levels of precision and efficiency.For manufacturers, the importance of cutting tools cannot be overstated. They are the critical component that enables precise and efficient machining, which in turn enables the production of high-quality finished products. With a world-class supplier like this company, manufacturers can be confident that they are getting cutting tools that are engineered to perform at the highest level, no matter what materials they are cutting or what application they are being used for.

Revolutionary Floor Polishing Pads Set to Transform Diamond Polishing Industry

[Company Name] Revolutionizes the Diamond Floor Polishing Industry[City, State] - In an industry first, [Company Name], a leading provider of floor polishing solutions, has introduced a game-changing product that is set to revolutionize the diamond floor polishing market. By combining cutting-edge technology with their years of experience, [Company Name] has developed a line of floor polishing pads that offer unparalleled quality and performance.With a strong commitment to innovation and continuous improvement, [Company Name] has always been at the forefront of the industry. They have consistently strived to develop products that meet the evolving needs of their customers, and their recent breakthrough is a true testament to their dedication.The new line of diamond floor polishing pads developed by [Company Name] boasts several key features that set them apart from the competition. Firstly, they are engineered with precision and crafted from the highest quality materials. This ensures durability and longevity, making them a cost-effective solution for any floor polishing project.Additionally, the pads are designed to offer exceptional performance and efficiency. The advanced technology used in the manufacturing process enables them to remove scratches, stains, and marks from a variety of flooring surfaces, including marble, granite, terrazzo, and concrete, with ease. This saves time and effort, making the diamond floor polishing process quicker and more convenient for professionals and do-it-yourself enthusiasts alike.The innovative design of [Company Name]'s diamond floor polishing pads also enables them to deliver a superior finish. The unique composition and tight particle distribution create a smooth and glossy surface that enhances the appearance of any floor. Regardless of the condition of the floor, these pads are capable of restoring it to its former glory, leaving the surface looking brand new.Moreover, [Company Name] understands the importance of sustainability in the current global landscape. Their diamond floor polishing pads are produced with eco-friendly materials, minimizing their impact on the environment without compromising on quality. As sustainability continues to be a growing concern for businesses and consumers alike, [Company Name] aims to provide solutions that align with this ethos.The launch of these state-of-the-art diamond floor polishing pads is a significant milestone for [Company Name]. They have not only solidified their position as an industry leader but have also demonstrated their commitment to pushing boundaries and revolutionizing the market. With the introduction of this ground-breaking product, [Company Name] hopes to set new standards in the diamond floor polishing industry and cater to the diverse and evolving needs of their customers.Furthermore, [Company Name] takes pride in their exceptional customer service. They have a team of dedicated professionals who are passionate about assisting clients every step of the way, ensuring a smooth and successful floor polishing experience. Their commitment to excellence extends beyond the initial purchase, as [Company Name] provides ongoing support and guidance to help users make the most of their diamond floor polishing pads.In conclusion, [Company Name] has redefined the diamond floor polishing industry with its innovative line of floor polishing pads. With unparalleled quality, performance, and eco-friendly features, these pads are set to become the go-to solution for professionals and enthusiasts alike. Through its continuous drive for innovation, [Company Name] proves once again that they are committed to meeting and exceeding customer expectations, paving the way for a new era in floor polishing.

Revamp Your Concrete Flooring with a Diamond Grinding Machine

Diamond Grinding Machine Floor: The Game Changer in the Flooring Industry For those in the flooring industry, the Diamond Grinding Machine Floor is a game changer. This highly-advanced machine that uses diamond technology has made a significant contribution to the flooring industry. Its ability to polish and grind surfaces, remove coatings and level and prepare floors has always been beneficial for the industry.As a leading provider of diamond grinding machines, we at XYZ have been at the forefront of this innovation. Our machines are designed to provide the ultimate solution for challenging surface preparation tasks while saving time and effort. We have combined the latest technology with the best materials to create a state-of-the-art machine that professionals rely on.The diamond grinding machine floor is engineered to grind, level, and clean concrete surfaces. With its powerful motor, this machine cuts through even the toughest surfaces and leaves them smooth and polished. Because it uses diamond technology, it is able to remove coatings such as epoxies, urethanes, and glues, which is something that other grinding machines can struggle with.Our machines are designed to be easy to operate, with an ergonomic handlebar for easy steering and an adjustable dust collection system. The dust collection system is key in the flooring industry, as it helps to keep the work area clean and helps to prevent the inhalation of harmful dust.The diamond grinding machine floor is also incredibly versatile and can be used on a variety of surfaces. From concrete floors to terrazzo, and even marble, this machine can do it all. This makes it an excellent addition to any flooring professional's toolkit.One of the most impressive features of our machines is the fact that they are environmentally friendly. Because they use diamond technology, they produce minimal dust and debris, making them perfect for use in areas where cleanliness is paramount.The Diamond Grinding Machine Floor has revolutionized the flooring industry and has become an essential tool for professionals. At XYZ, we understand the importance of producing high-quality machines that are built to last. We use only the best materials and the latest technology to ensure that our machines stand the test of time.Our machines are used in a variety of applications, from polishing concrete floors in commercial buildings to preparing floors for the installation of new tiles in homes. They are also used in the construction industry for cutting and preparing surfaces for the installation of new roads, sidewalks, and pavement.In conclusion, the Diamond Grinding Machine Floor is a game-changer in the flooring industry. Its ability to polish, grind, and level surfaces has made it an essential tool for professionals. With its powerful motor, versatility, and environmental friendliness, it's easy to see why it has become such a popular choice. At XYZ, we take pride in providing high-quality machines that are designed to last, and we will continue to innovate and improve our technology to meet the changing needs of the industry.