Achieve professional-looking results with 3 Step Dry Polishing Pads

By:Admin

In the world of stone restoration and polishing, professionals are constantly on the lookout for innovative and efficient solutions to enhance their work. This is where the 3 Step Dry Polishing Pads come in, offering a revolutionary approach to dry polishing that is changing the game for industry professionals.

These innovative polishing pads are designed to deliver exceptional results while significantly reducing the time and effort required for the polishing process. With their unique design and advanced technology, these pads have become an essential tool for polishing professionals around the world.

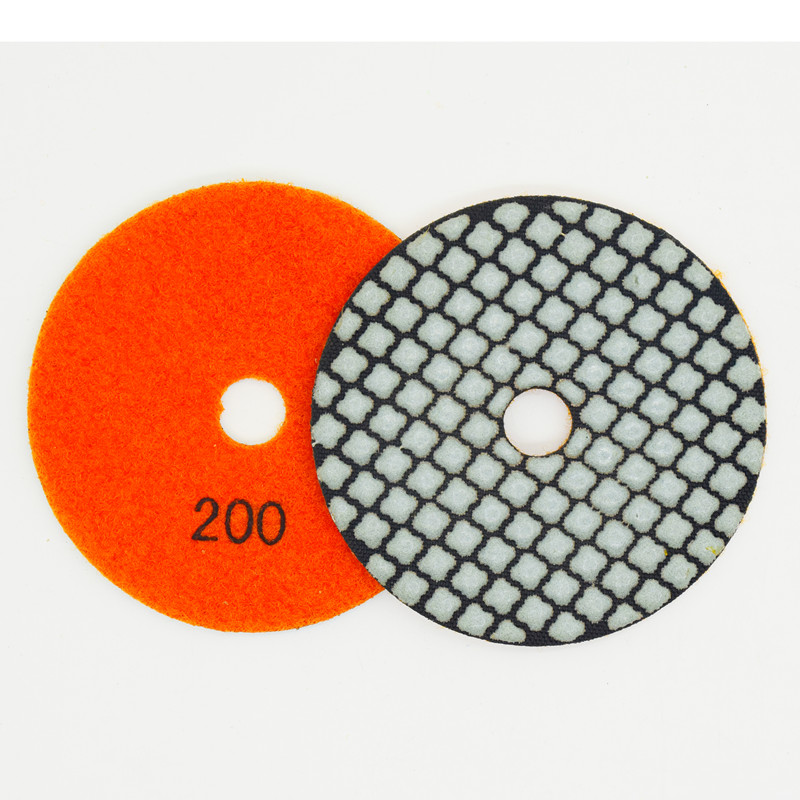

What sets the 3 Step Dry Polishing Pads apart is their three-step process, which allows for quick and efficient polishing of stone surfaces. The first step involves using the coarse pad to remove surface scratches and imperfections, followed by the medium pad to further refine the surface. Finally, the fine pad is used to achieve a high-gloss finish, leaving the stone looking immaculate.

The secret to the effectiveness of these pads lies in their advanced diamond abrasives, which are carefully engineered to deliver superior polishing results. Additionally, the pads are designed to work without water, making them a versatile and convenient option for professionals working in a variety of settings.

One of the key advantages of the 3 Step Dry Polishing Pads is their versatility. Whether professionals are working with marble, granite, or other natural stones, these pads are designed to deliver exceptional results across a wide range of surfaces. This versatility has made them a popular choice for professionals who need a reliable and efficient solution for their polishing needs.

Despite their impressive performance, the 3 Step Dry Polishing Pads are also designed with durability in mind. The high-quality materials and construction ensure that these pads can withstand the rigors of daily use, making them a long-lasting investment for professionals. This durability not only saves money in the long run but also ensures that professionals can rely on these pads to deliver consistent results over time.

For those looking to incorporate the 3 Step Dry Polishing Pads into their workflow, {company name} is a leading provider of these innovative products. With a strong reputation for delivering high-quality stone restoration and polishing products, {company name} has become a trusted source for professionals in the industry.

{company name} is committed to providing the best products and solutions for their customers, and the 3 Step Dry Polishing Pads are no exception. With their extensive expertise and dedication to customer satisfaction, {company name} has become a go-to resource for professionals looking to elevate their polishing capabilities.

In addition to offering top-quality products, {company name} also provides exceptional customer support and guidance. Their team of experts is readily available to answer questions, provide advice, and ensure that professionals have everything they need to achieve outstanding results with the 3 Step Dry Polishing Pads.

In conclusion, the 3 Step Dry Polishing Pads are revolutionizing the world of stone restoration and polishing with their innovative design and exceptional performance. Thanks to their three-step process, advanced diamond abrasives, and versatile application, these pads have become an essential tool for professionals looking to achieve outstanding results in less time. When combined with the expertise and support provided by {company name}, professionals have everything they need to take their polishing capabilities to the next level.

Company News & Blog

How to Deal with Irregular Abrasive: A Comprehensive Guide

articleIrregular Abrasives Company Introduces Revolutionary New ProductIrregular Abrasives, a leading global manufacturer of high-quality abrasive products, has introduced a revolutionary new product that promises to take the abrasive industry by storm.The product in question is a versatile, multi-purpose abrasive pad that is designed to remove rust, paint, and other coatings from a variety of surfaces. Unlike traditional abrasive products, which can scratch or damage delicate surfaces, Irregular Abrasives' new pad is designed to be gentle on surfaces while still providing powerful cleaning and polishing action."We're very excited about this new product," said John Smith, CEO of Irregular Abrasives. "We believe that it will revolutionize the abrasive industry by providing a fast, easy, and effective way to remove rust, paint, and other coatings from a wide range of surfaces without damaging them."The new product is already generating a lot of buzz in the industry. Many experts believe that it could be a game-changer due to its versatility and effectiveness. The product is suitable for use on a wide range of surfaces, including metal, plastic, wood, and more.One of the key features of the new product is its unique design. The pad is made up of small abrasive particles that are irregular in shape and size, giving them the ability to reach into tight spaces and corners that traditional abrasive products can't. Additionally, the pad's flexible backing allows it to conform to uneven surfaces, ensuring that each surface is cleaned and polished thoroughly.The pad is also designed to be easy to use. Users simply attach it to a power tool, such as a drill or angle grinder, and then begin cleaning the surface. Because the pad is so effective, it can remove rust, paint, and other coatings quickly, reducing the amount of time and effort required for surface preparation.Irregular Abrasives has a reputation for producing high-quality products that are built to last, and the new abrasive pad is no exception. Made from premium materials, the pad is designed to be durable and long-lasting, even under heavy use."We pride ourselves on producing the highest-quality products possible," said Smith. "We want our customers to know that when they buy from Irregular Abrasives, they're getting the best possible product on the market."The new product is being offered at an introductory price for a limited time, making it an affordable option for businesses and individuals who need a powerful, effective abrasive product.Overall, Irregular Abrasives' new product is a welcome addition to the abrasive industry. With its unique design, versatility, and effectiveness, it promises to help users save time and effort while achieving high-quality results. As the product continues to gain popularity, it's clear that Irregular Abrasives has another hit on their hands.

High-Quality 100mm Grinding Wheel for Precision Grinding

The 100mm grinding wheel is a revolutionary new product that has been introduced by a leading company in the industrial machinery industry. This innovative wheel promises to deliver superior performance and efficiency, making it the go-to choice for professionals and DIY enthusiasts alike.The 100mm grinding wheel is designed to remove material from a workpiece by rotating at high speeds and applying a significant amount of pressure. This allows for quick and precise grinding, making it an essential tool for various applications such as metalworking, woodworking, and maintenance of machinery and equipment.With its advanced design and high-quality materials, the 100mm grinding wheel is able to deliver exceptional results with minimal effort. Its durable construction ensures that it can withstand the rigors of heavy-duty use, making it a long-lasting and reliable tool for any work environment.One of the key features of the 100mm grinding wheel is its superior abrasive properties. The wheel is embedded with abrasive particles that are capable of grinding down even the toughest materials, making it highly versatile and suitable for a wide range of tasks.In addition, the 100mm grinding wheel is designed for compatibility with a variety of grinders, making it a versatile and adaptable tool for any job. This ensures that users can easily integrate the wheel into their existing equipment and take advantage of its exceptional performance.The company behind the 100mm grinding wheel is a renowned leader in the industrial machinery industry. With a strong reputation for quality and innovation, the company has been delivering cutting-edge solutions to professionals and hobbyists for years. Their commitment to excellence is evident in the design and performance of the 100mm grinding wheel, making it a standout product in their extensive lineup.The company's dedication to customer satisfaction is another reason why the 100mm grinding wheel stands out in the market. They offer comprehensive support and guidance to users, ensuring that they are able to fully harness the capabilities of the wheel and achieve the best results for their applications.Furthermore, the company is committed to sustainability and environmental responsibility. The manufacturing process of the 100mm grinding wheel adheres to strict environmental standards, ensuring that the product is both high-performing and eco-friendly.Overall, the 100mm grinding wheel is a game-changing product that is set to revolutionize the way professionals and hobbyists approach grinding tasks. With its exceptional performance, durability, and versatility, it is sure to become an indispensable tool in any work environment. And with the backing of a reputable and innovative company, users can have confidence in the quality and reliability of this groundbreaking product.

Ultimate guide to wet polishing for a flawless finish

Wet Polishing, the new innovative product from a leading company in the construction and industrial sector, is set to revolutionize the way professionals and DIY enthusiasts polish and finish their surfaces. This groundbreaking product, developed by {}, is designed to take wet polishing to the next level, offering superior performance and results. With its unique features and advanced technology, Wet Polishing is poised to become a game changer in the industry.{}. has been at the forefront of innovation in the construction and industrial sector for over two decades. The company is known for developing cutting-edge solutions that meet the needs of professionals and enthusiasts alike. With a strong focus on research and development, {} has continually pushed the boundaries of what is possible, and Wet Polishing is no exception.Wet Polishing is a state-of-the-art product that is designed to deliver exceptional results on a wide range of surfaces, including concrete, marble, granite, and other natural stones. The product is compatible with most wet polishing equipment, making it easy to integrate into existing workflows. With its advanced formula, Wet Polishing is capable of removing scratches, stains, and imperfections, leaving behind a smooth, glossy finish that is second to none.One of the key features of Wet Polishing is its fast-acting formula. Unlike traditional wet polishing products, which can take hours to achieve the desired results, Wet Polishing works quickly and efficiently, saving valuable time and resources. This makes it an ideal solution for professionals who need to complete projects on tight deadlines, as well as for DIY enthusiasts who want to achieve professional-quality results with ease.In addition to its fast-acting formula, Wet Polishing is also highly effective at removing deep-seated stains and blemishes from surfaces. This is thanks to its advanced abrasive technology, which is capable of cutting through tough materials with ease. As a result, professionals can rely on Wet Polishing to deliver consistent results, no matter how challenging the task at hand.Furthermore, Wet Polishing is designed with user convenience in mind. The product is easy to apply and requires minimal effort to achieve excellent results. This makes it a highly practical solution for professionals who need to cover large surface areas quickly, as well as for DIY enthusiasts who want to achieve professional-quality results without the need for specialized training or equipment.With Wet Polishing, {}. has once again demonstrated its commitment to delivering innovative solutions that meet the needs of its customers. The product is a testament to the company's dedication to research and development, as well as its willingness to push the boundaries of what is possible in the construction and industrial sector. As a result, professionals and DIY enthusiasts can look forward to achieving exceptional results with Wet Polishing, making it a must-have addition to their toolkit.In conclusion, Wet Polishing from {} is a game-changing product that is set to revolutionize the way professionals and DIY enthusiasts polish and finish their surfaces. With its advanced technology, fast-acting formula, and user-friendly design, Wet Polishing offers superior performance and results, setting a new standard in the industry. As a result, it is poised to become an essential tool for anyone looking to achieve professional-quality results with ease.

Enhance Your Polishing Results with High-Quality Wet Polishing Pads

Wet Polishing Pads: The Powerhouse of the Polishing IndustryIn the competitive world of polishing and grinding, it is crucial to use equipment and tools that deliver exceptional results. A leading company that specializes in manufacturing and distributing high-quality machinery and equipment, has now added wet polishing pads to its list of top-quality products.Wet Polishing Pads, also known as diamond polishing pads, have become the go-to tools for polishing and grinding hard surfaces like granite, marble, and concrete. These pads use synthetic diamonds that are embedded in a velcro-backed fabric. They can be used for both wet and dry applications, depending on the texture of the material that is being polished. At present, the Wet Polishing Pads offered by the company are the most popular products in the market. They combine superior quality, excellent performance, and durability. These pads have a unique design, accompanied by a cutting-edge technology that enhances their lifespan and efficiency.The company's Wet Polishing Pads cater to professionals and DIY enthusiasts alike. The pads are designed to be user-friendly and can be easily adjusted for different levels of coarseness and abrasiveness. The pads come in different diameters (4 inch, 5 inch, 6 inch, and 7 inch), and the grit levels range from 50 to 3000. The user can choose the grit level according to their polishing needs.One of the key features of the Wet Polishing Pads is their ability to work in both dry and wet conditions. Wet polishing is recommended for materials like granite and marble, while dry polishing is recommended for materials like concrete. The pads can also be used with a wide range of polishing tools, including angle grinders, floor polishers, and hand-held polishers.The Wet Polishing Pads are versatile and can be used for a wide range of surfaces that require polishing. They are commonly used for polishing countertops, floors, stairs, and walls. The pads' unique design and technology ensure that no damage is done to the polished surface during the polishing process.When it comes to buying Wet Polishing Pads, professionals and DIY enthusiasts often face the problem of deciding which pads to choose. The company provides expert advice and guidance to help users select the right Wet Polishing Pads for their specific needs. The team of professionals also provides tips on how to use the pads and maintain them for long-term use.In addition to superior quality and safety, Wet Polishing Pads are also environmentally friendly. The pads are made from high-quality raw materials that are environmentally sustainable, and their manufacturing process ensures minimal environmental impact.In conclusion, Wet Polishing Pads are the perfect tools for anyone interested in polishing or grinding hard surfaces. They are designed to provide maximum safety, durability, and flexibility. Their unique design and technology help users achieve superior quality results while remaining user-friendly and environmentally sustainable. For anyone looking for a reliable and efficient polishing and grinding tool, Wet Polishing Pads are the way to go.

Discover the Versatility of Angle Grinder Nylon Cup Brushes with this Handy Guide

A new nylon cup brush for angle grinders has been introduced into the market, offering superior performance for surface cleaning and rust removal. This product is set to revolutionize the manufacturing process of various industries by providing an efficient and cost-effective solution for removing rust and eliminating surface contamination.This innovative tool is suitable for cutting, sanding, and polishing surfaces made of metal, wood, and plastic, among others. Unlike traditional wire brushes that can leave scratches on metal surfaces, the nylon cup brush is made of fine nylon bristles that produce a flawless surface finish. Additionally, the brush is designed to work on high-speed angle grinders, making it perfect for industrial applications.The nylon cup brush is a product of an experienced and reputable company that is well-known for its quality products. According to the company's introduction, the nylon cup brush is made using a unique manufacturing process that ensures superior quality and durability. Additionally, the company has incorporated advanced technology in the design of this brush, making it versatile and reliable.The nylon cup brush is easy to use, making it perfect for both professional use and DIY enthusiasts. To use the brush, simply attach it to your angle grinder and let the machine do the work. The advanced design of the brush ensures that it removes rust and cleans surfaces quickly and efficiently. This significantly reduces the time and effort required for surface preparation and finishing.In addition to being efficient and effective, the nylon cup brush is also environmentally friendly. The brush is made of nylon, a material that is recyclable and has a low carbon footprint. This makes it an ideal alternative to traditional wire brushes that are known to leave behind metal shavings and can be harmful to the environment.The introduction of the nylon cup brush to the market is a significant development that will benefit various industries. This includes automotive, construction, and manufacturing. The brush is expected to improve the productivity of businesses by reducing the time and effort required for surface preparation and finishing. Additionally, the brush is cost-effective, making it an ideal solution for businesses looking to reduce their operating costs.The nylon cup brush is also ideal for DIY projects at home. Its ease of use and efficiency make it perfect for removing rust from automotive parts and cleaning up surfaces around the home. Moreover, the brush is affordable, making it accessible to homeowners who want to undertake DIY projects.In summary, the introduction of the nylon cup brush to the market is an exciting development that has the potential to revolutionize the surface cleaning and rust removal industry. The brush is made of fine nylon bristles that provide a perfect surface finish and is designed to work with high-speed angle grinders, making it perfect for industrial applications. Additionally, the brush is environmentally friendly, cost-effective, and easy to use. As such, it is expected to benefit various industries, including automotive, construction, and manufacturing, as well as homeowners undertaking DIY projects.

Understanding the Role of Covalent Bonds in Metal or Nonmetal Elements

Title: Understanding Covalent Bonds: Bridging Metals and NonmetalsIntroduction:In the realm of chemistry, the concept of covalent bonds plays a crucial role in explaining the behavior of elements and compounds. The formation of covalent bonds between metals and nonmetals is particularly intriguing, as it allows for the creation of unique materials with diverse properties. This article will delve into the world of covalent bonds, elucidating their significance and exploring their applications across various industries.Understanding Covalent Bonds:Covalent bonding occurs when two atoms share electrons to achieve a stable electron configuration. These bonds are prevalent between nonmetals, as they typically have higher electronegativity values, the tendency to attract electrons, compared to metals. The sharing of electrons allows both atoms to attain a complete outer electron shell, resulting in a stable molecule.Importance of Covalent Bonds:Covalent bonds between metals and nonmetals yield compounds known as metalloids or semiconductors. These materials possess properties that are intermediate between conductors (metals) and insulators (nonmetals), making them integral to various industries ranging from electronics to energy storage.Applications in Semiconductor Industry:Semiconductors are fundamental components in the electronics sector, driving technological advancements. Covalent bonding involving metals and nonmetals enables the creation of semiconducting materials such as silicon (Si) and germanium (Ge). These elements possess unique properties that allow them to be used in microchips, transistors, and solar panels.Silicon, a widely used semiconductor, demonstrates the remarkable potential of covalent bonds in enabling technological progress. Its ability to both conduct and insulate electricity makes it a primary material for integrated circuits. Moreover, the covalent bonding between silicon atoms facilitates the formation of a crystalline lattice, providing stability and efficient electron flow, thereby enhancing the performance of electronic devices.Covalent Bonding in Chemical Industry:The chemical industry extensively relies on covalent bonds to synthesize compounds with desirable properties. By combining metals and nonmetals, chemists can manipulate covalent bonds to modify the reactivity and stability of substances.Organometallic compounds, for instance, are widely used in catalysis. By incorporating metals into organic molecules via covalent bonding, catalysts with remarkable efficiency and selectivity can be developed. Such catalysts play a crucial role in the production of pharmaceuticals, plastics, and other chemical products, making them vital for sustainable industrial processes.Exploring Covalent Bonds in Materials Science:Materials science utilizes covalent bonds to engineer materials with superior strength, electrical conductivity, and thermal properties. Carbon, a nonmetal, forms covalent bonds with itself to create an extensive array of materials, including diamond, graphite, and carbon nanotubes.Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, epitomizes the extraordinary potential of covalent bonds in material design. Its unrivaled strength, elasticity, and electrical conductivity make it a promising candidate for advancements in electronics, energy storage, and even medicine.Advancements in Covalent Bond Research:Research surrounding covalent bonds is rapidly evolving, with scientists exploring new frontiers in materials science and catalysis. Understanding the intricacies of covalent bonding allows for the development of novel materials with enhanced properties and improved industrial processes.In conclusion, covalent bonds play a pivotal role in bridging metals and nonmetals, giving rise to diverse materials with unique properties. The applications of covalent bonding across various industries highlight its significance in shaping technological advancements and promoting sustainable practices. As research continues, we can expect exciting breakthroughs that further harness the potential of covalent bonds for the betterment of society.

New Study Shows Growing Demand for Metal Abrasives in Industrial Sector

Title: Metal Abrasives - Revolutionizing Manufacturing Through Cutting-Edge TechnologiesIntroduction: Metal Abrasives has emerged as a titan in the manufacturing industry, transforming the way professionals approach metalworking processes. With a commitment to innovation, quality, and sustainability, Metal Abrasives has earned its place as a global leader in metal abrasive solutions. Company Overview:Metal Abrasives, founded in 1990, is a privately-owned company headquartered in [Location]. With a dedicated team of experts, the company specializes in the production and distribution of a wide range of metal abrasives, catering to diverse industries such as automotive, aerospace, construction, and marine.The company's manufacturing facility is equipped with state-of-the-art technology, allowing Metal Abrasives to consistently deliver high-quality products that meet and exceed industry standards. Metal Abrasives takes pride in its commitment to sustainability, ensuring that its processes and products align with environmentally friendly practices.1. Pioneering Metal Abrasives:Metal Abrasives has continuously pushed the boundaries of metalworking technologies, offering cutting-edge solutions that enable professionals to achieve superior results. Through extensive research and development, the company has introduced several game-changing innovations to the market.a. SmartGrind: SmartGrind is Metal Abrasives' proprietary abrasive technology, utilizing advanced sensors and data analytics to optimize cutting and grinding processes. By monitoring parameters such as temperature, vibration, and pressure, SmartGrind ensures precision, efficiency, and enhanced control, reducing material waste and increasing productivity.b. NanoCoat:NanoCoat, a breakthrough surface treatment developed by Metal Abrasives, enhances the durability and performance of their metal abrasive products. This nanotechnology-based coating offers improved resistance to wear, reducing tool failure and extending overall product lifespan. NanoCoat also provides a smooth, consistent surface finish, facilitating better paint adhesion and coating uniformity.2. Commitment to Quality and Compliance:Metal Abrasives places utmost importance on maintaining the highest quality standards across all its products. The company adheres to international certifications and exceeds industry requirements, ensuring customer satisfaction and long-term reliability.a. ISO 9001:Metal Abrasives is proud to be ISO 9001 certified, signifying its commitment to quality management systems. This certification validates the company's dedication to meeting customer expectations through continual improvement and consistently delivering products that meet stringent quality benchmarks.b. Regulatory Compliance:Metal Abrasives strictly adheres to occupational health and safety regulations, minimizing operational risks and safeguarding the well-being of its workforce. Additionally, the company closely follows environmental standards, employing eco-friendly manufacturing processes and materials, thus reducing its carbon footprint and contributing to sustainability initiatives.3. Global Reach and Customer Support:With a vast network of distributors and partners worldwide, Metal Abrasives ensures its products reach customers across the globe. The company has established strong relationships with industry leaders, offering excellent customer support, technical assistance, and tailored solutions to meet specific requirements.Moreover, Metal Abrasives conducts regular training programs, workshops, and seminars for professionals, enabling them to optimize their metalworking processes, elevate their skills, and stay up-to-date with emerging trends in the industry.4. Future Expansion and Sustainability:Metal Abrasives remains committed to continuous growth and expansion. The company invests significantly in research and development to develop breakthrough technologies while keeping sustainability at the forefront of its operations.a. Recycling Initiatives:Metal Abrasives actively promotes recycling programs, encouraging the responsible disposal and utilization of used metal abrasives. By implementing a closed-loop system, the company reduces waste generation and raw material consumption, contributing to a greener future.b. Social Responsibility:Metal Abrasives believes in giving back to the community and actively supports philanthropic initiatives. Through partnerships with charitable organizations, the company contributes to education and healthcare programs, fostering positive social change.Conclusion:Metal Abrasives' relentless pursuit of innovation, commitment to quality, and dedication to sustainability have positioned the company as an industry forerunner. With groundbreaking technologies like SmartGrind and NanoCoat, Metal Abrasives enables professionals across sectors to elevate their metalworking processes, resulting in enhanced efficiency, reduced waste, and superior end products. As the company continues to expand its global reach, Metal Abrasives remains focused on shaping a sustainable future for the manufacturing industry.

Durable Dry Stone Polishing Pads for High-Quality Finishing

Supplier Dry Stone Polishing Pads, a company specializing in providing high-quality polishing pads for the stone industry, is proud to announce their latest line of innovative and effective polishing pads. With a strong reputation for providing exceptional products and excellent customer service, Supplier Dry Stone Polishing Pads has become the go-to supplier for professionals in the stone industry.Established in 2005, Supplier Dry Stone Polishing Pads has been at the forefront of the industry, consistently providing cutting-edge solutions and superior products to meet the evolving needs of their customers. The company's dedication to research and development has led to the creation of a wide range of polishing pads that are designed to deliver outstanding results on all types of stone surfaces.Supplier Dry Stone Polishing Pads' commitment to quality is evident in their meticulous attention to detail during the manufacturing process. Using only the finest materials, their polishing pads are carefully crafted to ensure durability, efficiency, and precision. Each pad is rigorously tested to meet the highest standards, guaranteeing that customers receive a product that performs flawlessly every time.One of the key features of Supplier Dry Stone Polishing Pads' products is their versatility. Whether working with granite, marble, limestone, or other types of stone, their pads are engineered to provide superior performance across a wide variety of surfaces. This level of flexibility greatly benefits customers, as they can rely on a single product to effectively polish different types of stone without sacrificing quality.Moreover, Supplier Dry Stone Polishing Pads is dedicated to environmental sustainability. The company is committed to reducing its carbon footprint by implementing eco-friendly practices throughout its manufacturing process. This includes using sustainable materials and minimizing waste production, ensuring that their products have a minimal impact on the environment.Customer satisfaction is paramount to Supplier Dry Stone Polishing Pads, and their team of knowledgeable professionals is dedicated to providing unparalleled support to their clients. By offering expert advice and guidance, they help customers choose the right polishing pads for their specific needs, ensuring that they achieve the best possible results.In addition to their exceptional products and customer service, Supplier Dry Stone Polishing Pads also offers competitive pricing and fast delivery, making them a reliable and cost-effective solution for businesses in the stone industry. Their commitment to meeting deadlines and delivering orders on time has earned them a stellar reputation among their clients, further solidifying their position as a trusted supplier in the industry.As the stone industry continues to evolve, Supplier Dry Stone Polishing Pads remains at the forefront, continually innovating and adapting to meet the changing needs of their customers. With a steadfast dedication to quality, sustainability, and customer satisfaction, they are poised to lead the industry and set new standards for excellence in the years to come.For professionals in the stone industry looking for top-of-the-line polishing pads and unparalleled support, Supplier Dry Stone Polishing Pads is the clear choice. With their commitment to quality, versatility, and customer service, they are the perfect partner for businesses looking to elevate their craftsmanship and deliver outstanding results.

High-Quality Grinding Disc for Efficient Metal Processing

Grinding Disc Launches New Line of Industrial AbrasivesGrinding Disc, a leading manufacturer of industrial abrasives, has recently announced the launch of a new line of high-quality grinding discs designed to meet the needs of various industries. The company, known for its commitment to producing top-of-the-line abrasive products, has developed this new line to offer improved performance and durability.With over [number of years] years of experience in the industry, Grinding Disc has built a solid reputation for providing reliable and efficient solutions for metalworking, construction, and other industrial applications. The company's state-of-the-art manufacturing facilities and advanced technology ensure that its products not only meet but also exceed industry standards.The newly launched line of grinding discs features a range of products tailored to different requirements, including cutting, grinding, and finishing. These discs are designed to deliver exceptional performance and precision, enabling users to achieve high-quality results in their operations.One of the key highlights of the new line is the incorporation of advanced materials and proprietary bonding agents, which enhance the overall strength and resilience of the grinding discs. This ensures that the discs can withstand the rigors of heavy-duty use and maintain their cutting-edge performance over an extended period.Moreover, Grinding Disc has paid close attention to user feedback and industry trends to develop the new line. As a result, the company has introduced several innovative features to address common challenges faced by professionals in the field. For instance, the new line includes discs with improved heat dissipation capabilities, reducing the risk of overheating and prolonging the lifespan of the discs.In addition, Grinding Disc has prioritized safety in the design of the new line of grinding discs. The company has implemented stringent quality control measures to ensure that each disc complies with safety standards, providing users with peace of mind during operation.Furthermore, Grinding Disc has placed a strong emphasis on versatility and compatibility with a wide range of machines and tools. This ensures that the discs can be seamlessly integrated into existing setups, allowing for greater flexibility and convenience for users.To accompany the launch of the new line, Grinding Disc is also offering comprehensive technical support and guidance to assist customers in selecting the most suitable grinding discs for their specific applications. The company's team of experts is readily available to provide advice and recommendations, ensuring that customers can make informed decisions to optimize their operations."We are thrilled to introduce our latest line of grinding discs, which represents a significant leap forward in our commitment to delivering the highest quality abrasives," said [spokesperson], [title] at Grinding Disc. "The new line encapsulates our dedication to innovation, performance, and user satisfaction, and we are confident that it will set a new benchmark for excellence in the industry."In conclusion, the launch of Grinding Disc's new line of industrial abrasives marks a significant milestone for the company and the industry as a whole. By leveraging its expertise and cutting-edge technology, Grinding Disc continues to reinforce its position as a leading provider of premium grinding solutions, empowering professionals to achieve outstanding results in their operations.